- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

1月 . 14, 2025 12:00

Back to list

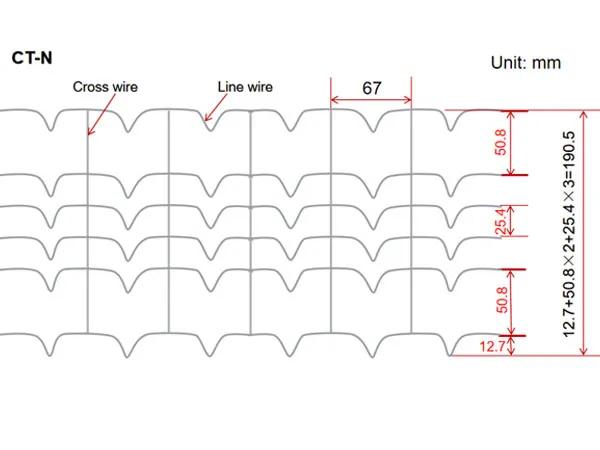

Shale Shaker Screen

Navigating the complex landscape of shale shaker screen pricing involves a keen understanding of the industry dynamics underpinned by prominent factors such as material quality, mesh size, screen type, and market trends. Shale shaker screens, essential in the oil and gas drilling industry, demand due diligence from procurement specialists to secure the best value without compromising quality—here's why.

Authoritativeness in the procurement of these screens is exhibited by a strong grasp of market dynamics. Price fluctuations can occur due to various factors, including raw material availability and geopolitical influences affecting the shipping and availability of the screens. Trustworthy vendors who have established relationships in the market can offer competitive pricing through strategic sourcing and bulk purchasing, passing the savings to their clients. The pricing strategy should also take into account the screen's compatibility with existing systems. Investing in non-compliant screens, even if initially cheaper, could result in costly operational delays. Trustworthy manufacturers and suppliers often provide detailed product manuals and compatibility assessments, enabling buyers to make informed decisions confidently. Trustworthiness in product and vendor selection is further bolstered by customer testimonials and third-party reviews that highlight past performance and reliability. A meticulous review of these endorsements can reveal insights into product longevity and real-world performance, offering a meaningful benchmark against which potential purchases can be compared. Ultimately, achieving the balance between cost and quality when discussing shale shaker screen prices becomes a matter of informed decision-making founded on experienced evaluation, authoritative guidelines of industry standards, and a trust-based relationship with suppliers. Professionals actively engaged in the field can unlock significant value by leveraging this knowledge to enhance operational efficiency while managing the economics of drilling operations effectively. As the industry evolves, staying abreast of technological advancements and market conditions will continue to be crucial for making strategic purchase decisions and securing competitive pricing in shale shaker screens.

Authoritativeness in the procurement of these screens is exhibited by a strong grasp of market dynamics. Price fluctuations can occur due to various factors, including raw material availability and geopolitical influences affecting the shipping and availability of the screens. Trustworthy vendors who have established relationships in the market can offer competitive pricing through strategic sourcing and bulk purchasing, passing the savings to their clients. The pricing strategy should also take into account the screen's compatibility with existing systems. Investing in non-compliant screens, even if initially cheaper, could result in costly operational delays. Trustworthy manufacturers and suppliers often provide detailed product manuals and compatibility assessments, enabling buyers to make informed decisions confidently. Trustworthiness in product and vendor selection is further bolstered by customer testimonials and third-party reviews that highlight past performance and reliability. A meticulous review of these endorsements can reveal insights into product longevity and real-world performance, offering a meaningful benchmark against which potential purchases can be compared. Ultimately, achieving the balance between cost and quality when discussing shale shaker screen prices becomes a matter of informed decision-making founded on experienced evaluation, authoritative guidelines of industry standards, and a trust-based relationship with suppliers. Professionals actively engaged in the field can unlock significant value by leveraging this knowledge to enhance operational efficiency while managing the economics of drilling operations effectively. As the industry evolves, staying abreast of technological advancements and market conditions will continue to be crucial for making strategic purchase decisions and securing competitive pricing in shale shaker screens.

Share

Prev:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025