- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

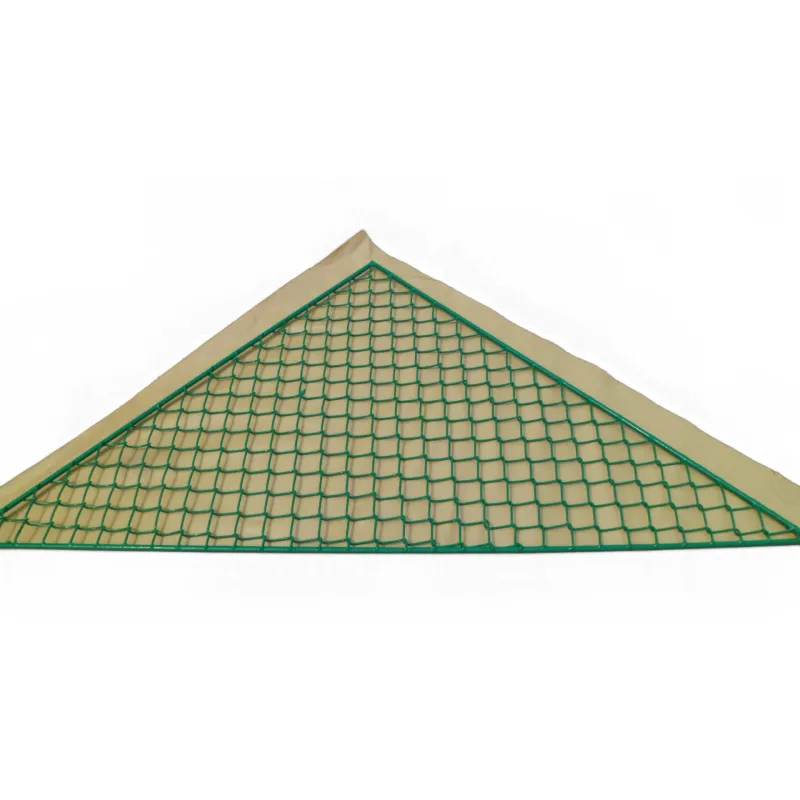

Durable Plastic Frame Shaker Screens for Enhanced Filtration and Performance

The Evolution and Importance of Plastic Frame Shaker Screens

In the world of industrial filtration and separation, shaker screens play a pivotal role in ensuring efficiency and performance. One of the noteworthy advancements in this field is the introduction of plastic frame shaker screens. The evolution from traditional metal frames to plastic alternatives has brought significant benefits to various industries, including oil and gas, mining, and wastewater treatment. This article delves into the mechanics, advantages, and applications of plastic frame shaker screens.

Understanding Shaker Screens

Shaker screens are utilized in a variety of processes to separate solids from liquids or to classify materials based on size. They are integral components in shakers, which use vibration to facilitate the separation process. Traditionally, these screens were made from metal frameworks, providing durability but often at the cost of weight and ease of handling.

With the advent of plastic frame shaker screens, companies have begun to see a shift in how these tools are perceived and utilized. Plastic frames typically consist of high-density polyethylene (HDPE) or other robust plastic materials. These innovations have not only improved the performance of shaker screens but have also introduced several advantages over their metal counterparts.

Advantages of Plastic Frame Shaker Screens

1. Lightweight Design One of the primary benefits of plastic frame shaker screens is their lightweight nature. The reduced weight makes them easier to transport, install, and replace. In industries where efficiency is paramount, this can save both time and labor costs.

2. Corrosion Resistance Plastic frames are inherently resistant to corrosion and rust, a significant advantage in environments where exposure to chemicals and harsh conditions is common. This property extends the lifespan of the screens and reduces maintenance costs.

3. Cost-Effectiveness While the initial investment in plastic frames might be comparable to metal options, the long-term savings due to reduced repairs, replacements, and maintenance make plastic screens a more economical choice.

4. Enhanced Performance The design flexibility of plastic allows for various mesh sizes and configurations. This adaptability ensures optimal performance across different applications, which is crucial in processes that require precise separation.

plastic frame shaker screen

5. Environmental Impact Many plastic frame shaker screens are now being produced using recycled materials, making them a more environmentally friendly option. Furthermore, their durability means less frequent replacements, contributing to lower material waste over time.

Applications of Plastic Frame Shaker Screens

The versatility of plastic frame shaker screens allows them to be employed in a wide range of industries. Here are some notable applications

- Oil and Gas In drilling operations, shaker screens are essential for separating drilling fluids from cuttings. The enhanced characteristics of plastic frames can greatly improve the efficiency of this process.

- Mining In the mining industry, shaker screens are used for separating ore from waste materials. The lightweight nature of plastic frames reduces the overall load on machinery, leading to improved operational efficiency.

- Wastewater Treatment Plastic frame shaker screens are also used in the treatment of wastewater, where they help filter out solids from liquid effluents. Their resistance to corrosion makes them particularly suitable for this application.

- Food and Beverage In the food industry, maintaining hygiene is of utmost importance. Plastic frames can be designed for easy cleaning and are less likely to harbor bacteria compared to metal frames.

Conclusion

Plastic frame shaker screens represent a significant innovation in the field of filtration and separation. Their lightweight, corrosion-resistant design, along with cost-effectiveness and versatility, positions them as an excellent choice across various industries. As technological advancements continue to evolve, the reliance on plastic frame shaker screens is likely to grow, underscoring their importance in modern industrial processes.

In summary, as industries seek to enhance performance while minimizing environmental impact, the adoption of plastic frame shaker screens could very well become a standard practice, setting the stage for a more efficient and sustainable future in industrial filtration.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025