- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

2月 . 14, 2025 07:23

Back to list

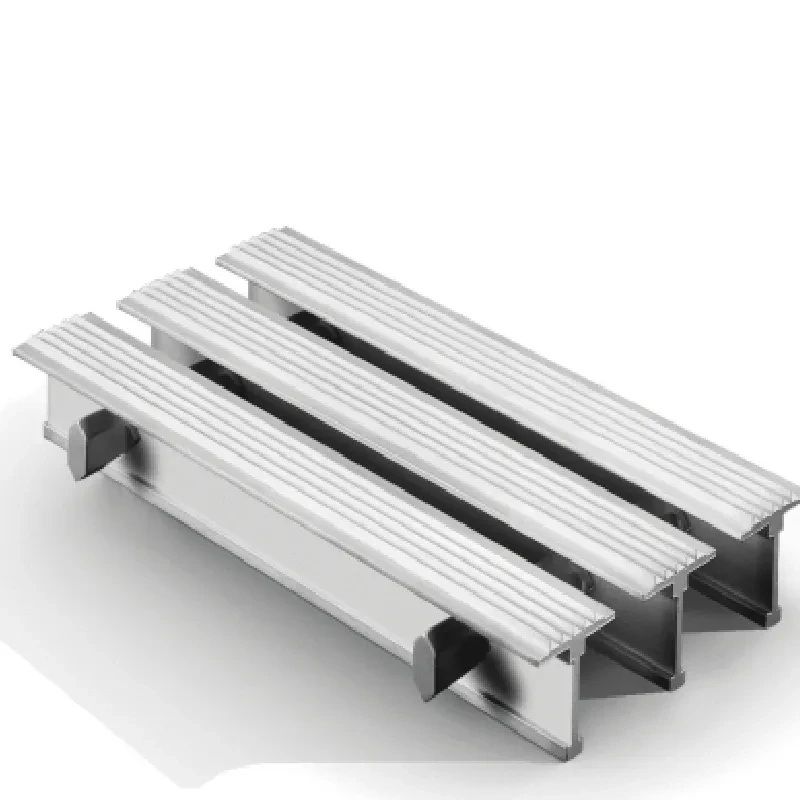

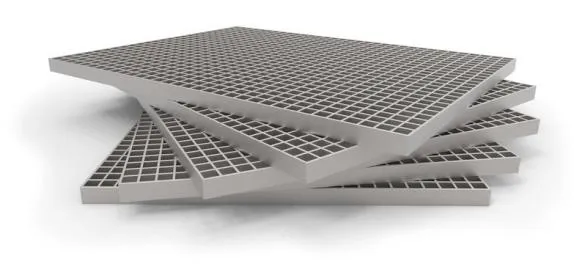

bar grating weight

In the realm of industrial flooring solutions, bar grating stands out as a versatile and resilient choice, providing strength and stability across a myriad of applications from industrial walkways to urban drainage systems. One significant consideration in the selection process is understanding the bar grating weight, a critical factor influencing everything from installation ease to structural support, and ultimately, project success.

Safety considerations also hinge greatly on weight, as heavy gratings can pose risks during lifting and installation if adequate safety measures are not in place. Lighter gratings reduce these risks and offer greater flexibility in installation, allowing for adjustments and repositioning with minimal effort. Moreover, the weight of bar grating impacts its long-term maintenance requirements. Heavier gratings, typically more robust, tend to offer enhanced durability and less frequent need for replacement, leading to reduced lifecycle costs. Conversely, lighter options might require more regular inspections and maintenance to ensure their longevity and safety. In terms of environmental impact, lighter gratings contribute to reduced carbon footprint during transportation and installation. Moreover, depending on the material, gratings can be recyclable, aligning with sustainable construction practices. Selecting the right bar grating involves striking a balance between weight, material properties, and the specific needs of the application. Engaging with experts in the field, seeking advice from seasoned engineers, and consulting with manufacturers can provide invaluable insights, ensuring informed decisions that align with project goals and compliance with industry standards. Every grating buyer and installer must consider weight alongside other performance metrics to achieve efficient, safe, and cost-effective installations. With the right analysis and professional guidance, bar grating can indeed transform from a basic functional element into a strategic component that enhances operational efficiency and safety across various industrial and commercial landscapes.

Safety considerations also hinge greatly on weight, as heavy gratings can pose risks during lifting and installation if adequate safety measures are not in place. Lighter gratings reduce these risks and offer greater flexibility in installation, allowing for adjustments and repositioning with minimal effort. Moreover, the weight of bar grating impacts its long-term maintenance requirements. Heavier gratings, typically more robust, tend to offer enhanced durability and less frequent need for replacement, leading to reduced lifecycle costs. Conversely, lighter options might require more regular inspections and maintenance to ensure their longevity and safety. In terms of environmental impact, lighter gratings contribute to reduced carbon footprint during transportation and installation. Moreover, depending on the material, gratings can be recyclable, aligning with sustainable construction practices. Selecting the right bar grating involves striking a balance between weight, material properties, and the specific needs of the application. Engaging with experts in the field, seeking advice from seasoned engineers, and consulting with manufacturers can provide invaluable insights, ensuring informed decisions that align with project goals and compliance with industry standards. Every grating buyer and installer must consider weight alongside other performance metrics to achieve efficient, safe, and cost-effective installations. With the right analysis and professional guidance, bar grating can indeed transform from a basic functional element into a strategic component that enhances operational efficiency and safety across various industrial and commercial landscapes.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025