- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

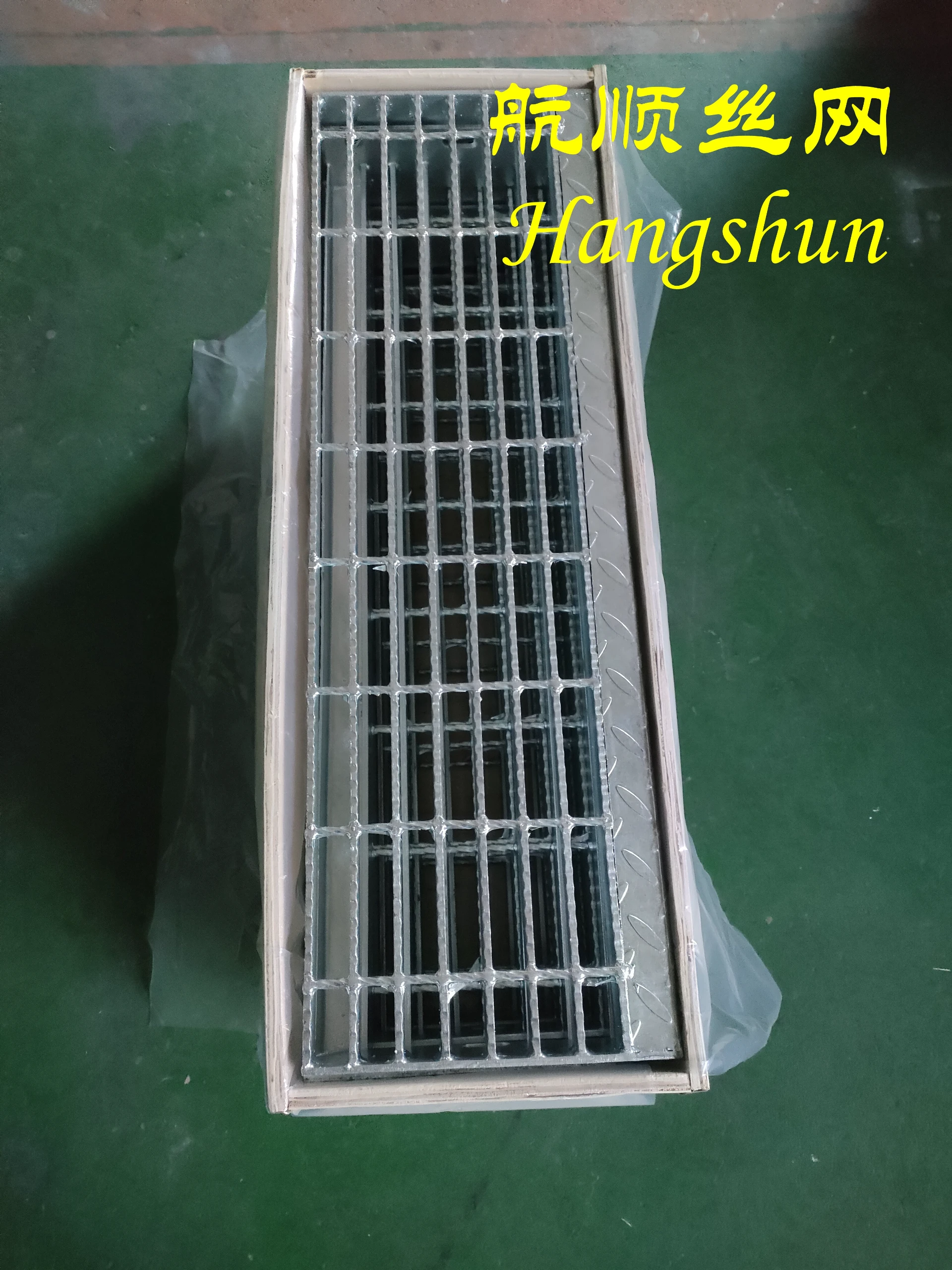

galvanized serrated grating

Understanding Galvanized Serrated Grating An Essential Component in Industrial Applications

Galvanized serrated grating is an innovative and essential material utilized in various industries due to its unique properties and advantages. This type of grating is constructed from steel or other metals and undergoes a galvanization process, which involves coating the metal with a layer of zinc to enhance its resistance to corrosion. The serrated design, characterized by its ridged surface, provides additional slip resistance and structural integrity. In this article, we will explore the features, benefits, applications, and maintenance of galvanized serrated grating.

Features of Galvanized Serrated Grating

Galvanized serrated grating typically comes in various materials, including mild steel, stainless steel, and aluminum. However, the galvanization process is primarily applied to steel to combat rust and deterioration in harsh environments. The grates are engineered in different shapes and sizes, including rectangular, square, and round openings, depending on the specific application requirements.

The serrated edges of the grating offer substantial advantages. Their design enhances grip and traction, making them ideal for surfaces exposed to wet or slippery conditions. Additionally, serrated grating can maintain its structural integrity under heavy loads, making it an excellent choice for flooring applications in industrial settings.

Advantages of Using Galvanized Serrated Grating

1. Corrosion Resistance The galvanization process creates a protective barrier against moisture and corrosive substances, significantly extending the lifespan of the grating. This feature is crucial in environments prone to high humidity, temperature fluctuations, and chemical exposure.

2. Safety The slip-resistant serrated surface reduces the risk of accidents caused by slipping, making it suitable for walkways, platforms, and stairs in factories, warehouses, and industrial sites.

3. Lightweight yet Durable Galvanized serrated grating is designed to bear heavy loads while remaining lightweight. This characteristic simplifies transportation, installation, and maintenance, ultimately reducing labor costs.

4. Versatile Applications Due to its durability and versatile design, galvanized serrated grating is widely used in various applications, including pedestrian walkways, platform flooring, drain covers, and machinery guards. It is also employed in water treatment facilities and power plants where safety and durability are paramount.

galvanized serrated grating

Common Applications

Galvanized serrated grating finds applications in multiple sectors, including

- Manufacturing and Warehousing In factories and warehouses, it serves as flooring for walkways and work platforms, ensuring employee safety and providing strong load-bearing capabilities.

- Construction Used in scaffolding and temporary structures, serrated grating can support heavy materials and workers efficiently while minimizing the risk of falls.

- Waste Management In wastewater treatment plants, galvanized grating is commonly utilized for catwalks and platforms that require high corrosion resistance due to exposure to chemicals and moisture.

- Mining and Oil & Gas The oil and gas industry benefits from its strength and durability under harsh environmental conditions, making it suitable for offshore platforms and mining operations.

Maintenance of Galvanized Serrated Grating

One of the major advantages of galvanized serrated grating is its low maintenance requirement. Regular inspections for any signs of wear, damage, or accumulated debris are advisable to ensure safety and functionality. Cleaning can be performed with water and mild detergents, particularly in environments with corrosive substances to prevent buildup that could affect performance.

Conclusion

In conclusion, galvanized serrated grating is a vital component in various industrial applications, offering numerous benefits, including corrosion resistance, safety enhancements, and cost-effectiveness. Its unique design and material properties make it an indispensable choice for businesses aiming to enhance safety and efficiency in their operations. As industries continue to evolve, the demand for durable and reliable materials like galvanized serrated grating is likely to grow, solidifying its role as a backbone of industrial safety and design.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025