- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

what is bar grating

What is Bar Grating?

Bar grating, also known as grating or metal grating, is a common architectural and construction material comprised of a series of parallel bars or slats that are typically spaced apart to create a grid-like structure. These gratings serve various functional purposes ranging from flooring to drainage, and they can be found in both industrial and commercial applications.

Types of Bar Grating

Bar grating can be crafted from various materials, but the most common include steel, aluminum, and fiberglass. The choice of material depends largely on the intended use, environmental conditions, and cost considerations.

1. Steel Bar Grating This is the most widely used type due to its strength and durability. Steel gratings are often coated to prevent rust and corrosion, making them suitable for outdoor applications and harsh environments.

2. Aluminum Bar Grating Aluminum is lighter than steel and resistant to corrosion, making it an excellent choice for applications in humid or marine environments. It is also easier to install and handle due to its lighter weight.

3. Fiberglass Bar Grating This type is made from a combination of fiberglass and resin, providing a non-conductive and non-corrosive alternative. Fiberglass gratings are often used in environments with high levels of moisture and chemical exposure, such as chemical plants or wastewater treatment facilities.

Design and Construction

Bar grating is typically manufactured using one of two methods welded or press-locked.

- Welded Grating In this method, the load-bearing bars are welded to the cross bars, providing a strong and stable grid. This design is ideal for heavy-load applications and can withstand significant weight without bending or breaking.

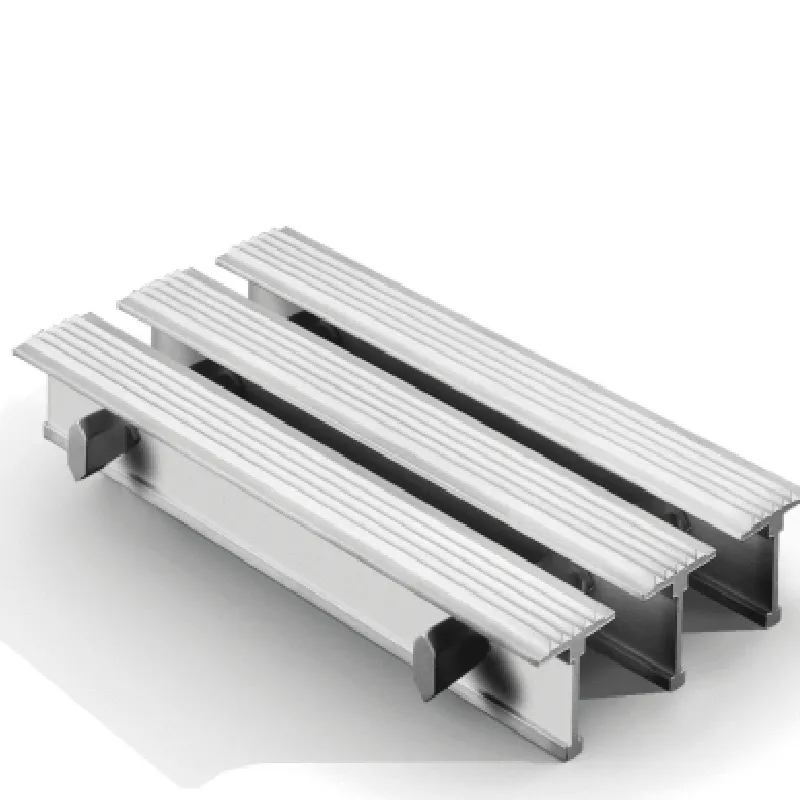

- Press-Locked Grating This involves inserting the load bars into pre-made slots on the cross bars, which are then pressed together to form a tight fit. This type of grating is more cost-effective than welded grating and provides resistance against twisting and slipping.

Most bar gratings are available in custom sizes and configurations to accommodate specific project requirements. Bar spacing, thickness, and overall dimensions can be tailored to meet load-bearing specifications, ensuring safety and performance.

Applications of Bar Grating

what is bar grating

Bar grating is highly versatile, making it suitable for a variety of applications

- Industrial Flooring Bar grating is commonly used as flooring in manufacturing and industrial facilities where heavy equipment and vehicles operate. Its open design allows for effective drainage, reducing the risk of slips and falls.

- Walkways and Platforms The slip-resistant surface and ability to hold considerable weight make bar grating the preferred material for walkways, platforms, and catwalks in various settings, including power plants, petrochemical facilities, and food processing plants.

- Drainage Systems Bar grating is often utilized in drainage systems to cover drainage channels, providing a sturdy surface that allows water to flow while preventing debris from clogging the system. This is especially important in outdoor applications and municipal systems.

- Safety Barriers In many industries, bar gratings serve as barriers or guards for machinery and equipment, helping to prevent accidents and injuries. Their transparent design allows for visibility while maintaining safety.

Advantages of Bar Grating

Bar grating offers numerous advantages that contribute to its popularity

- Strength and Durability Steel and aluminum gratings provide high load capacity, ensuring reliable performance in heavy-duty applications.

- Lightweight Compared to solid alternatives, bar grating is lightweight, making it easier to handle, transport, and install.

- Corrosion Resistance Many gratings come with protective coatings, enhancing their longevity when exposed to harsh environmental conditions.

- Low Maintenance Bar grating requires minimal maintenance, often just periodic cleaning to prevent buildup of debris.

- Cost-Effective With various materials and designs available, bar grating can be a cost-effective solution providing high functionality without excessive expenditure.

In conclusion, bar grating is an essential material used across a wide range of industries and applications. Its versatility, strength, and low maintenance requirements make it an attractive choice for developers, architects, and engineers looking to create safe and functional spaces. Whether it’s for flooring, walkways, or drainage solutions, bar grating continues to be an integral component of modern design and infrastructure.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025