- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Shale Shaker Screen: Precise Mesh, Fast Delivery, Low Price?

shale shaker screen, shale shaker screen mesh, shale shaker screen price, shale shaker screen china, shale shaker screen factory is a key solution in the energy industry, specifically within Oil and Gas and Oil and gas drilling and production equipment and services. This article explores how Anping County Hangshun Wire Mesh Manufacture Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- shale shaker screen, shale shaker screen mesh, shale shaker screen price, shale shaker screen china, shale shaker screen factory Overview

- Benefits & Use Cases of shale shaker screen, shale shaker screen mesh, shale shaker screen price, shale shaker screen china, shale shaker screen factory in Oil and gas drilling and production equipment and services

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in energy

- Conclusion on shale shaker screen, shale shaker screen mesh, shale shaker screen price, shale shaker screen china, shale shaker screen factory from Anping County Hangshun Wire Mesh Manufacture Co., Ltd

shale shaker screen, shale shaker screen mesh, shale shaker screen price, shale shaker screen china, shale shaker screen factory Overview

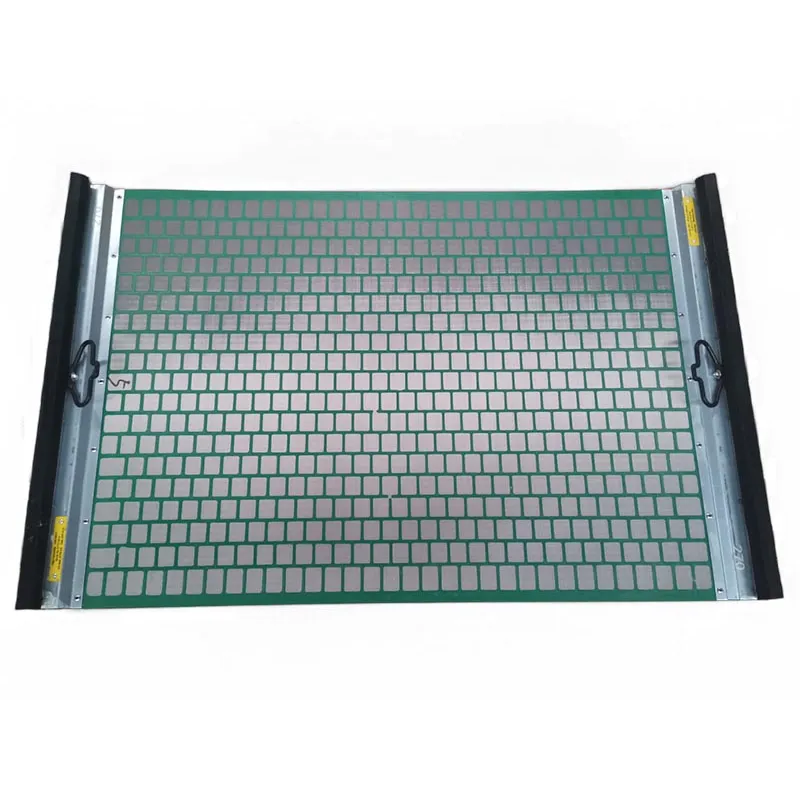

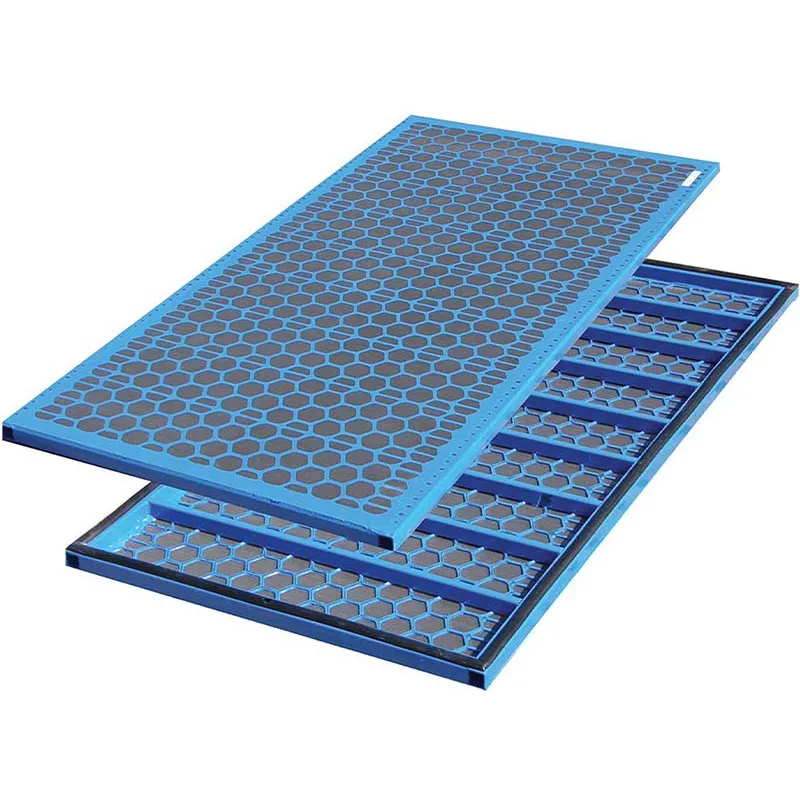

In modern drilling fluids systems, the shale shaker screen is the first and most critical line of defense for solids control. Installed on primary shakers, it separates drilled cuttings from mud to protect downstream equipment, maintain rheology, and reduce dilution rates. A high-quality shale shaker screen mesh—typically composed of multi-layer stainless steel woven cloth bonded to composite or steel frames—balances fine cuttings removal with high conductance to keep flow rates stable. API RP 13C labeling guides selection across API 20–325 ranges depending on lithology and mud weight. Anping County Hangshun Wire Mesh Manufacture Co., Ltd engineers screens compatible with leading shaker brands, including configurations for hook strip, pretensioned panel, and composite frame designs. Precision bonding, consistent mesh count, and robust perimeter sealing help minimize bypass and screen blinding. For B2B decision makers seeking reliability, a partner with deep manufacturing experience matters: the company’s controlled sourcing of SS304/SS316 mesh, rigorous tension control, and fit-checked frames deliver predictable performance across land and offshore applications. Whether optimizing for fluid clarity in water-based mud or maximizing flow capacity in oil-based mud, Hangshun’s portfolio offers the mesh gradations and build options to match diverse drilling programs.

Benefits & Use Cases of shale shaker screen, shale shaker screen mesh, shale shaker screen price, shale shaker screen china, shale shaker screen factory in Oil and gas drilling and production equipment and services

Across exploration, development, and workover operations, shale shaker screens protect drilling economics by removing solids early. Typical use cases include conventional land rigs, high-ROP unconventional horizontal wells, HP/HT environments, and offshore platforms where deck space and handling frequency are tightly managed. Selecting the right shale shaker screen mesh can reduce mud losses, extend centrifuge life, and stabilize MWD/LWD data quality by maintaining cleaner mud. Key advantages delivered by Anping County Hangshun Wire Mesh Manufacture Co., Ltd include high conductance multi-layer screens for aggressive ROP, anti-blinding patterns for sticky shales, and rugged composite frames that resist warping under thermal and mechanical stress. Tight tolerances and accurate API designation allow faster screen selection, while interchangeable panels improve fleet logistics for rigs operating mixed shaker fleets (e.g., Derrick, NOV Brandt, M-I SWACO, and FSI compatibility). For HSE-conscious operators, improved cuttings dryness reduces waste handling volume and lowers disposal cost. In directional and extended-reach wells, where solids loading spikes during slide/rotate cycles, the company’s durable edge bonding and reliable gasket seals reduce premature failures, keeping shakers online and improving overall solids control efficiency.

Cost, Maintenance & User Experience

For procurement teams, total cost of ownership depends on more than just the shale shaker screen price. It’s a function of screen life (hours per section), flow capacity, change-out frequency, fluid savings, and downstream wear reduction. With robust frames and consistent mesh bonding, screens from Anping County Hangshun Wire Mesh Manufacture Co., Ltd help lower cost per foot by minimizing nonproductive time tied to screen failures or excessive washouts. Buyers sourcing from a trusted shale shaker screen factory in China often realize a favorable landed cost without sacrificing API compliance or quality consistency. Maintenance best practices—such as proper deck alignment, correct tensioning, routine washdown, and timely rotation of panels—extend usable life and preserve conductance. Many drilling teams report fewer gasket leaks and more stable cuttings discharge when using correctly spec’d mesh and composite frames, leading to cleaner pits and less dilution. From a logistics perspective, standardized packaging, clear API labeling, and reliable delivery windows reduce inventory carrying cost. The net ROI shows up as lower fluid consumption, reduced disposal volume, and fewer unscheduled change-outs—benefits that compound over multi-well pads and long drilling campaigns.

Sustainability & Market Trends in energy

Solids control is central to ESG performance. Effective shale shaker screens reduce mud dilution, conserve base fluids, and minimize cuttings waste, directly supporting emissions reduction and cost control targets. Regulations and operator standards continue to push for better waste minimization, improved cuttings dryness, and safer screen handling. Market trends favor composite frames for lighter handling, corrosion resistance, and longer service life, alongside mesh designs that maintain conductance while refining cut points. Digital traceability and API-compliant labeling aid quality assurance across global supply chains, especially when sourcing from a shale shaker screen china supplier. Anping County Hangshun Wire Mesh Manufacture Co., Ltd invests in material optimization, efficient curing/bonding processes, and recyclable packaging to lower embodied energy. The company collaborates with customers to match mesh selections to geology and mud programs, cutting unnecessary consumption and elevating circularity in the drilling fluids ecosystem. As operators adopt performance-based contracts and data-driven maintenance, the demand for consistent, high-performing screens—and a responsive shale shaker screen factory partner—continues to grow.

Conclusion on shale shaker screen, shale shaker screen mesh, shale shaker screen price, shale shaker screen china, shale shaker screen factory from Anping County Hangshun Wire Mesh Manufacture Co., Ltd

A well-chosen shale shaker screen directly impacts drilling efficiency, fluid quality, and project economics. By combining accurate shale shaker screen mesh selection, durable frames, and tight quality control, Anping County Hangshun Wire Mesh Manufacture Co., Ltd delivers dependable performance with a competitive shale shaker screen price from a proven shale shaker screen china manufacturer. For B2B decision makers, partnering with a specialized shale shaker screen factory ensures supply reliability, compatibility, and measurable ROI across diverse drilling programs.

Contact us: email: sales@hfpetromesh.com

Visit our website: https://www.hfpetromesh.com | Product page: Shale Shaker Screen

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025