- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

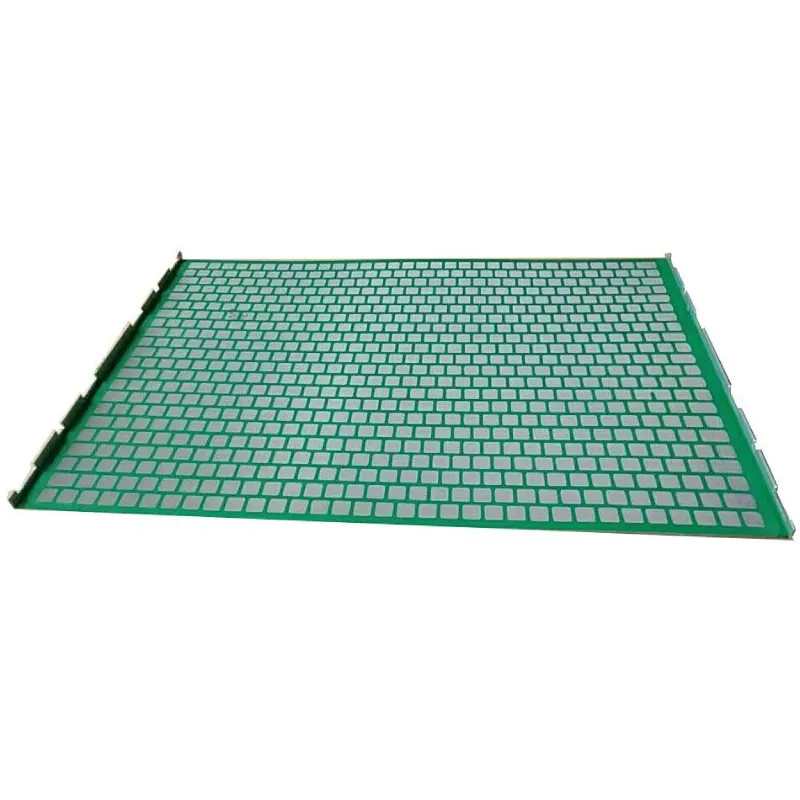

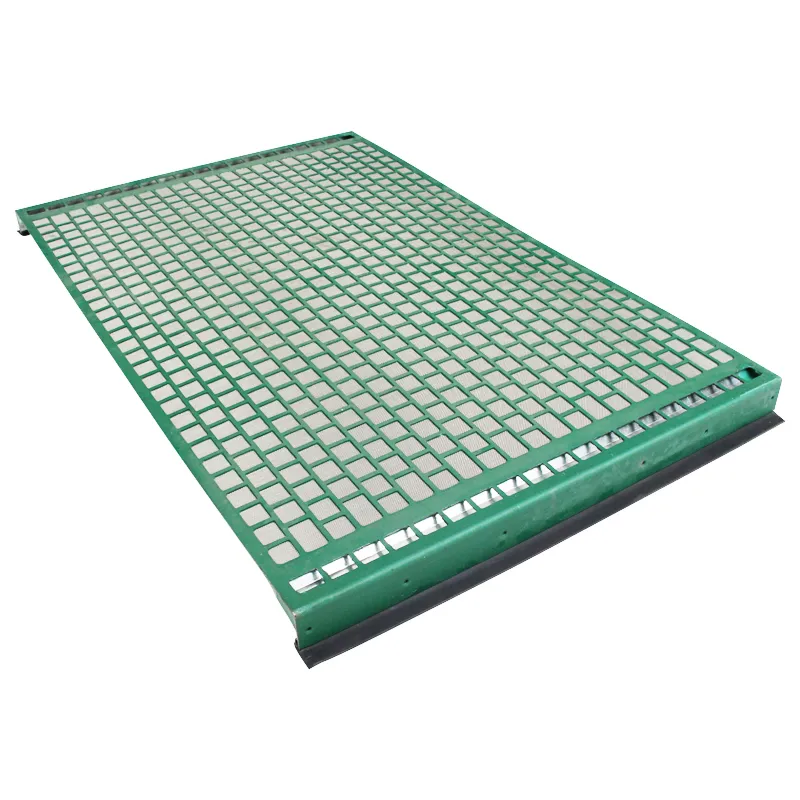

Shale Shaker Screen—API-Rated, Durable, Factory Price?

Hook Strip Flat Screen: field notes, pitfalls, and how to spec it right

If you’ve spent time around a mud system, you already know the humble shale shaker screen does the quiet heavy lifting. This piece—our Hook Strip Flat Screen from the industrial zone south of Anping, Hengshui, Hebei—has been earning its keep in drilling fluids control and waste management. To be honest, it’s the kind of component you only notice when it fails. The goal here: make sure it doesn’t.

What’s trending in solids control

Three shifts I’m seeing on rigs and recycling plants: tighter API separations, measurable conductance (not guesses), and screens built for fast swaps. Hook strip flat isn’t flashy, but it’s cost-efficient and easy to tension across a flat basket. Many customers say it feels old-school—until they see the numbers under API RP 13C testing.

Core specs (real-world values may vary)

| Parameter | Typical value ≈ | Notes |

|---|---|---|

| API designation range | API 20–325 | Per API RP 13C (D100 method) |

| D100 cut point | 840–44 μm | Depends on mesh count |

| Conductance | ≈ 1.2–6.5 kD/mm | Lab conditions; field mud varies |

| Material | SS304 / SS316 | Corrosion-resistant wire cloth |

| Layers | 2–4 | Backing + fine mesh configuration |

| Panel size | Common: 585×1165 mm; 630×1250 mm | Custom footprints on request |

How it’s built (quick process flow)

- Materials: SS304/SS316 woven wire; galvanized/SS hook strips; epoxy system formulated for oil-based or water-based muds (low VOC).

- Methods: precision wire weaving → pre-tensioning → layer stacking → adhesive bonding → hook strip crimping → edge sealing.

- Testing: API RP 13C D100 and conductance; flatness tolerance; mesh integrity; salt-spray per ASTM B117 on hooks.

- Service life: ≈ 300–800 hours depending on solids loading, flow rate, and drilling fluid chemistry.

- Industries: oil & gas, HDD, CBM, mining tailings, municipal waste management.

In fact, the most common failure we see isn’t wire fatigue—it’s improper tensioning. Take an extra minute on install; it pays back in days.

Vendor comparison (field-procurement snapshot)

| Vendor | Type | API Range | Avg. Life ≈ | Certs | Lead Time |

|---|---|---|---|---|---|

| HF PetroMesh Hook Strip Flat Screen | Hook strip flat | 20–325 | ≈ 450–700 h | ISO 9001; API RP 13C tested | Usually 5–10 days |

| Vendor A | Composite frame | 40–230 | ≈ 500–800 h | ISO 9001 | 7–14 days |

| Vendor B (economy) | Hook strip flat | 20–170 | ≈ 250–450 h | Factory QC only | 3–20 days |

Use cases and feedback

- Oil & Gas: switch from API 120 to 140 on top deck cut mud losses by ≈18% (Arabian onshore, OBM). Crew noted fewer blind-offs.

- HDD: Midwest contractor reports two extra shifts before first screen swap—“less babysitting,” as they put it.

- Waste management: higher conductance panels improved throughput around 12% on a thickened slurry line.

Customization? Absolutely: mesh counts, hook orientation, panel size, epoxy for OBM/WBM, and logo printing. From Anping, we ship fast and, surprisingly, packaging has gotten tougher—corner guards survive the roughest yards.

Quality notes, standards, and test data

A typical API 140 shale shaker screen we tested delivered D100 ≈ 106 μm and conductance ≈ 2.2 kD/mm in lab brine; real mud trimmed that by ~10–20%. Hooks cleared ASTM B117 48-hour exposure without red rust. Facility runs ISO 9001:2015 QMS, and panels are verified to API RP 13C labeling. Nothing fancy—just measurable, repeatable output.

Bottom line: if you want a durable shale shaker screen that doesn’t wreck your budget, hook strip flat is still a smart choice. And yes, installation matters. Tension evenly, re-check after warm-up, and keep solids distribution centered. It’s boring advice that works.

Citations

- API RP 13C: Recommended Practice on Drilling Fluids Processing Systems Evaluation and Testing (Shale Shaker Screens).

- IADC Drilling Manual, 12th Edition, Solids Control Chapter.

- ASTM B117: Standard Practice for Operating Salt Spray (Fog) Apparatus.

- ISO 9001:2015 Quality Management Systems—Requirements.

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025