- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Shale Shaker Screen - Anping County Hangshun Wire Mesh Manufacture Co., Ltd. | Drilling Efficiency, Durability

Shale shaker screens are critical components in the oil and gas industry, designed to separate drilling cuttings from mud (drilling fluid) during the extraction process. These screens are essential for maintaining the efficiency and sustainability of drilling operations. This article provides an in-depth exploration of the Shale Shaker Screen, including its features, technical specifications, applications, and the company behind this innovative product.

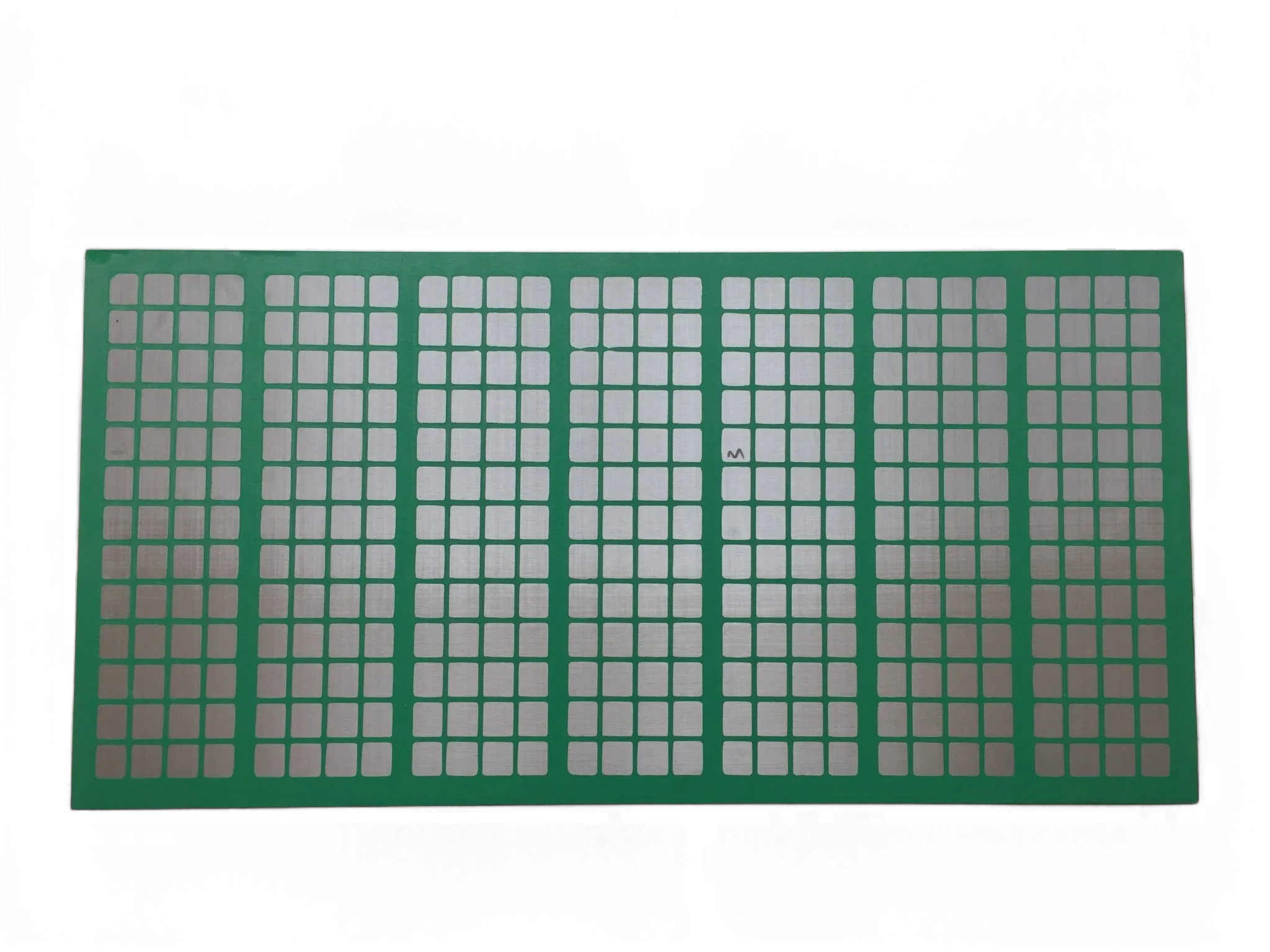

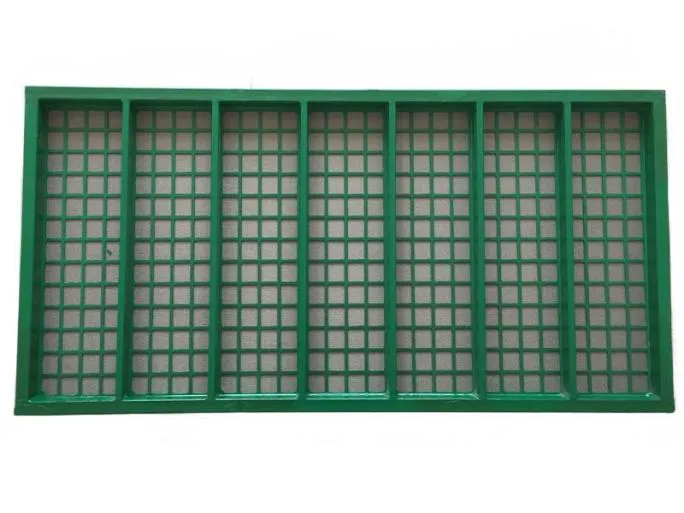

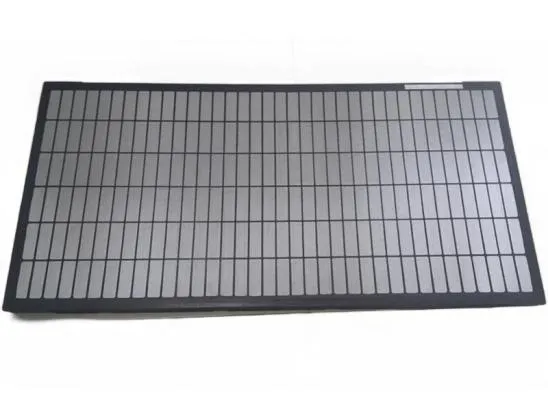

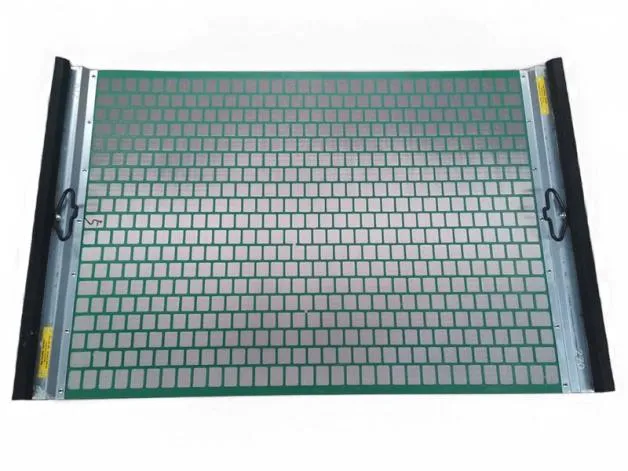

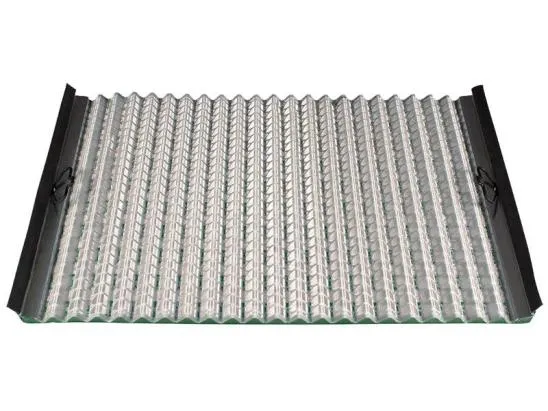

The Shale Shaker Screen is a fine mesh screen installed in shale shakers, typically composed of multiple layers of stainless steel wire cloth. This design allows for precise filtration of solid particles from drilling fluid, ensuring that only the cleanest fluid is recycled back into the system. The screen's structure is engineered to withstand the harsh conditions of drilling environments while maintaining high efficiency and durability.

Shale Shaker Screen is a mesh screen made of woven metal, designed to be used within shale shakers. When drilling equipment produces cuttings, they are coated in drilling liquid. As these cuttings are shaken over the screen, the mesh captures solid particles while allowing excess mud to drip through, which is then returned to the tank. This process is vital for maintaining the quality and consistency of drilling fluids, which directly impacts the efficiency of drilling operations.

The Shale Shaker Screen is available in various configurations, including dual or triple-layered structures. These layers are made of stainless steel wire cloths with different mesh sizes, ensuring optimal filtering accuracy. The product is designed to adapt to different drilling conditions, with options like wave screens offering high processing efficiency and steel frame screens providing superior weight-bearing capacity. This versatility makes the Shale Shaker Screen a valuable asset in diverse drilling scenarios.

Learn more about the Shale Shaker Screen and how it can enhance your drilling operations.

Key Features of Shale Shaker Screen

- High Strength and Load-Bearing Capacity: The Shale Shaker Screen is constructed with materials that ensure it can withstand the heavy loads of drilling fluids, making it ideal for demanding environments.

- Excellent Filtering Accuracy: The multi-layered design allows for precise separation of solids from liquids, ensuring that the drilling fluid remains clean and effective.

- High Processing Efficiency: The screen's design enhances the rate at which drilling cuttings are processed, contributing to overall operational efficiency.

- Wear and Corrosion Resistance: The use of stainless steel and other durable materials ensures that the screen can endure prolonged use without significant degradation.

- Flexibility: The Shale Shaker Screen is compatible with various types of shale shakers, allowing for easy integration into existing systems.

- Superior Appearance: The screen is manufactured to avoid defects such as bumps, deformation, or flash edges, ensuring a smooth and professional finish.

- Easy Installation and Maintenance: Designed for user convenience, the screen is straightforward to install and requires minimal maintenance, reducing downtime and operational costs.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | Stainless steel, carbon steel |

| Surface Treatment | Coating |

| Production Process | Weaving and perforating |

| Color | Black, green, blue (customizable) |

| Type | Steel or composite frame screen, hook strip screen, wave screen |

| Standards | ISO 13501, API RP 13C, GBT 11648, GBT 11650 |

Applications of Shale Shaker Screen

The Shale Shaker Screen is widely used in various industries where mud purification is essential. Its applications include:

- Oil Drilling: The screen is critical in separating cuttings from drilling fluids, ensuring the efficiency of drilling operations.

- Non-Excavation Horizontal Directional Crossing: Used to maintain the quality of drilling mud during directional drilling, reducing environmental impact.

- Coal Bed Methane Drilling: The screen helps in the efficient separation of solids, enhancing the productivity of methane extraction.

- Shale Gas Drilling: The high-performance design of the Shale Shaker Screen ensures effective filtration in challenging shale gas environments.

- Environmental Protection: The screen is used in river sludge treatment to purify mud and reduce pollution.

About Anping County Hangshun Wire Mesh Manufacture Co., Ltd.

Founded in 2005, Anping County Hangshun Wire Mesh Manufacture Co., Ltd. is a leading manufacturer of Shale Shaker Screen and other industrial wire mesh products. The company is dedicated to providing high-quality solutions for the oil and gas industry, with a focus on innovation and customer satisfaction.

With a strong commitment to quality and precision, Anping County Hangshun Wire Mesh Manufacture Co., Ltd. adheres to international standards such as ISO 13501 and API RP 13C. The company's state-of-the-art production facilities and rigorous quality control processes ensure that every product meets the highest standards of performance and reliability.

Industry Standards and Certifications

The Shale Shaker Screen is manufactured in compliance with several international standards, ensuring its reliability and performance in demanding environments. These include:

- ISO 13501: A standard that specifies the requirements for the design and testing of wire mesh screens.

- API RP 13C: A recommended practice for the design and operation of shale shakers, ensuring compatibility and efficiency.

- GBT 11648 and GBT 11650: Chinese national standards that govern the quality and performance of wire mesh products.

Why Choose Our Shale Shaker Screen?

The Shale Shaker Screen offers several advantages that make it a preferred choice for drilling operations:

- Enhanced Efficiency: The screen's design maximizes processing speed, reducing downtime and increasing productivity.

- Durability: Built to last, the screen is resistant to wear and tear, ensuring long-term performance.

- Customization: The company offers a range of options to meet specific drilling requirements, including different mesh sizes and frame types.

- Compliance: Adherence to international standards ensures that the product meets the highest quality and safety requirements.

References and Further Reading

The information provided in this article is based on industry standards and the expertise of Anping County Hangshun Wire Mesh Manufacture Co., Ltd. For further details on the standards and specifications of Shale Shaker Screen, refer to the following authoritative sources:

- National Institute of Standards and Technology (NIST) – Provides guidelines and standards for industrial equipment and materials.

References:

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025