- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Shaker Screen for Sale – Durable, API-Rated, Fast Shipping

shaker screen for sale,shaker screen,industrial shaker screen,shaker screen manufacturers is a key solution in the Oil and Gas industry, specifically within Oil and gas exploration and production services and equipment and Drilling solid control equipment and accessories. This article explores how Anping County Hangshun Wire Mesh Manufacture Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- shaker screen for sale,shaker screen,industrial shaker screen,shaker screen manufacturers Overview

- Benefits & Use Cases of shaker screen for sale,shaker screen,industrial shaker screen,shaker screen manufacturers in Drilling solid control equipment and accessories

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in Oil and Gas

- Conclusion on shaker screen for sale,shaker screen,industrial shaker screen,shaker screen manufacturers from Anping County Hangshun Wire Mesh Manufacture Co., Ltd

shaker screen for sale,shaker screen,industrial shaker screen,shaker screen manufacturers Overview

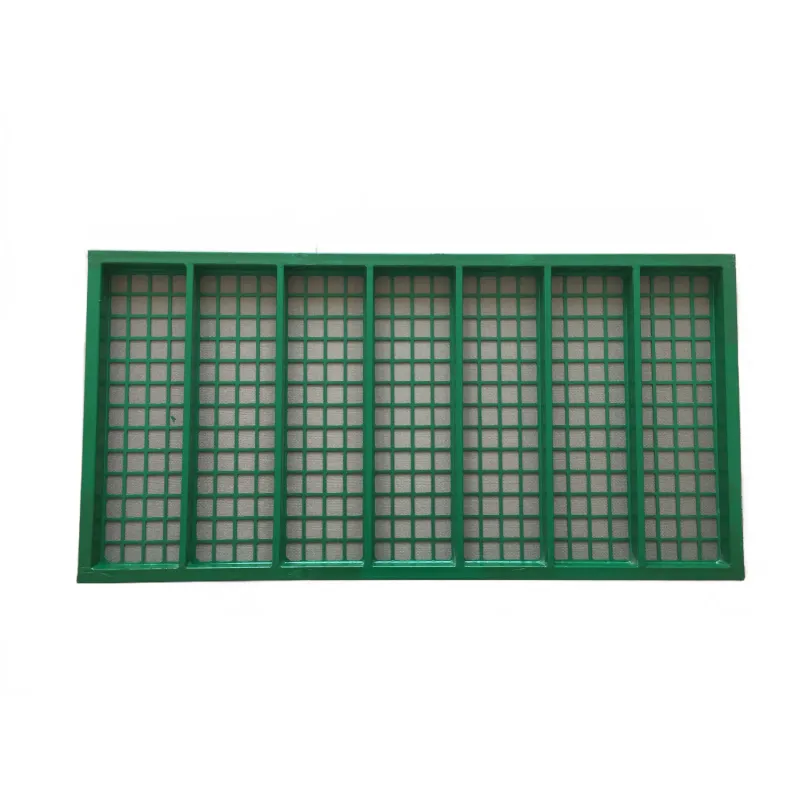

The shale shaker is the first line of defense in solids control, and the shaker screen is its core consumable. An industrial shaker screen separates drilled solids from drilling fluid, protecting downstream equipment, minimizing dilution, and improving overall mud quality. Anping County Hangshun Wire Mesh Manufacture Co., Ltd supplies steel-frame shale shaker screens engineered for rigorous oilfield duty, available in API RP 13C-compliant designations from coarse to ultra-fine. Typical construction includes multi-layer 304/316 stainless wire mesh with optimized open area, a rigid steel frame with reinforced ribs, and precision bonding that delivers consistent conductance and long service life.

For operators seeking a dependable shaker screen for sale, Hangshun’s portfolio covers flat and corrugated profiles, hook-strip and pre-tensioned frames, and compatibility with common shaker models. Screens are designed to maintain cut-point accuracy, resist blinding in both WBM and OBM, and reduce bypass. In a recent deployment on high-solids, high-G shakers, customers reported improved separation efficiency and reduced screen change-outs across a multi-well pad, highlighting the reliability of Hangshun’s industrial shaker screen solutions and their advantage over generic shaker screen manufacturers in terms of durability and quality control.

Benefits & Use Cases of shaker screen for sale,shaker screen,industrial shaker screen,shaker screen manufacturers in Drilling solid control equipment and accessories

In drilling solid control equipment and accessories, shaker screens are the primary barrier to protect desanders, desilters, and centrifuges. High-performance industrial shaker screens from Anping County Hangshun Wire Mesh Manufacture Co., Ltd enable sharper cut points, better recovery of weighted mud, and reduced dilution rates in both land and offshore operations. Whether on surface hole with large cuttings or on production intervals with finer solids and sticky clays, the right screen selection directly impacts rate of penetration, mud cost, and waste volumes.

Key advantages include:

- API RP 13C compliance for consistent D100 separation and conductance.

- Multi-layer stainless mesh and robust steel-frame construction for longer life in high G-force environments.

- Anti-blinding designs, precise sealing, and quick-fit locking to minimize bypass and speed change-outs.

- Broad compatibility with widely used shakers and tailored OEM/ODM options from experienced shaker screen manufacturers.

Use cases span high-solids spud mud, depleted reservoirs requiring finer screens, and high-density OBM where maximizing mud recovery is critical. Hangshun’s engineering team helps B2B decision makers select mesh grades and profiles to match formation, fluid type, and shaker parameters, ensuring optimal solids control performance and less nonproductive time.

Cost, Maintenance & User Experience

Total cost of ownership for a shaker screen is driven by screen life, separation efficiency, and the impact on mud costs and waste disposal. By maintaining a stable cut point and resisting premature failure, Hangshun screens help lower screen consumption per well and reduce dilution. Customers report fewer change-outs per section and improved mud recovery—benefits that translate into tangible savings on barite, base oil, and trucking.

Best practices to maximize ROI include:

- Match API designation to expected solids size and drilling parameters; avoid excessively fine screens early in hole.

- Ensure proper deck angle, tensioning, and sealing to prevent bypass and edge wear.

- Rotate screens by position and replace damaged panels promptly to protect downstream equipment.

From a user-experience standpoint, Hangshun’s industrial shaker screen panels feature clear labeling, robust perimeter seals, and packaging designed to prevent transit damage. B2B clients in oil and gas exploration and production services cite consistent quality lot-to-lot and responsive delivery schedules as key reasons for adopting this shaker screen for sale, noting 20–35% longer average life in demanding OBM compared with generic alternatives.

Sustainability & Market Trends in Oil and Gas

ESG goals and stricter regulations are reshaping solids control strategies. Efficient shaker screens reduce dilution and cuttings volume, lowering water use, chemical consumption, and waste hauling—key drivers of a rig’s carbon and cost footprint. As well designs grow more complex, the market is shifting to higher-capacity, finer API screens with improved conductance and anti-blinding features to maintain flow at tight cut points.

Anping County Hangshun Wire Mesh Manufacture Co., Ltd supports these trends with API RP 13C-compliant screening, quality systems aligned with international standards, and material choices focused on durability and recyclability. Steel-frame designs with corrosion-resistant finishes extend service life, while consistent mesh bonding reduces premature failures and waste. For procurement leaders seeking dependable shaker screen manufacturers, Hangshun offers stable supply, customization, and technical support that help operators reach sustainability targets without sacrificing performance.

Conclusion on shaker screen for sale,shaker screen,industrial shaker screen,shaker screen manufacturers from Anping County Hangshun Wire Mesh Manufacture Co., Ltd

For B2B decision makers, the right shaker screen can materially improve solids control performance, reduce mud costs, and lower waste volumes. Anping County Hangshun Wire Mesh Manufacture Co., Ltd delivers a reliable industrial shaker screen portfolio—API-compliant, durable, and compatible with leading shakers—making it a smart choice when evaluating a shaker screen for sale among global shaker screen manufacturers.

Contact us: email: sales@hfpetromesh.com

Visit our website: https://www.hfpetromesh.com

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025