- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

helideck netting

The Importance of Helideck Netting in Offshore Operations

In the realm of offshore operations, safety is paramount. With helicopters being a crucial mode of transportation for personnel and supplies to and from oil rigs and other maritime installations, the design and maintenance of helidecks have become increasingly sophisticated. One significant safety feature in this context is helideck netting. This specialized type of netting plays a vital role in enhancing safety for helicopter landings and takeoffs, reducing the risk of accidents, and ensuring personnel safety on helidecks.

Helideck netting is primarily designed to capture any objects that may fall from helicopters during landing or takeoff, or those that might be accidentally dropped by personnel on the helideck. The netting serves as a protective barrier that prevents these objects from falling into the water or onto the decks of vessels nearby, where they could pose serious hazards. This is especially important in offshore environments, where the risk of accidents can escalate quickly due to challenging weather conditions and operational pressures.

The materials used in helideck netting are engineered to withstand harsh marine environments. Typically constructed from high-strength synthetic fibers, these nets are resistant to corrosion and UV degradation, ensuring durability over time. The nets are designed to be lightweight yet robust, allowing them to endure impact without compromising the overall structural integrity of the helideck.

The installation of helideck netting is regulated by various international maritime safety standards. Compliance with these standards not only improves safety but also enhances operational efficiency. For instance, with effective netting in place, crews can focus more on their tasks, knowing that the risk of falling objects has been significantly minimized. This assurance fosters a more productive work environment, ultimately leading to better service delivery and reduced downtime.

helideck netting

Moreover, regular inspections and maintenance of helideck netting are critical. Assessing the condition of the netting ensures that any wear and tear are addressed promptly. Routine checks help in identifying potential issues before they escalate into more significant problems, potentially jeopardizing operations. Operators are encouraged to develop a thorough maintenance schedule as part of their safety protocols, thereby enhancing the overall safety culture within their operations.

Another key advantage of helideck netting is its contribution to pollution control. In the unfortunate event of an accident or spill, the netting can aid in containing any debris or hazardous materials, preventing them from spreading into the marine environment. This aspect is particularly significant for offshore facilities, where environmental regulations are stringent, and the protection of marine ecosystems is crucial.

Training and awareness among personnel is another integral part of ensuring the effectiveness of helideck netting. It is vital for crew members to understand the importance of the netting system and adhere to safety protocols. Regular training sessions that include emergency drills and safety briefings can reinforce the importance of these measures and prepare the crew for swift action in case of an emergency.

In conclusion, the installation of helideck netting is a crucial component of offshore safety. Through effective design, durable materials, and regulatory compliance, helideck netting significantly enhances safety for both personnel and equipment. Regular maintenance and personnel training further ensure that these systems function as intended, protecting lives and the environment. In an industry where safety can never be compromised, helideck netting stands out as a vital safety feature, reflecting the importance of proactive measures in managing the risks associated with offshore operations. As the offshore sector continues to evolve, ongoing innovations and adherence to best practices will remain essential in safeguarding operational integrity and personnel welfare.

-

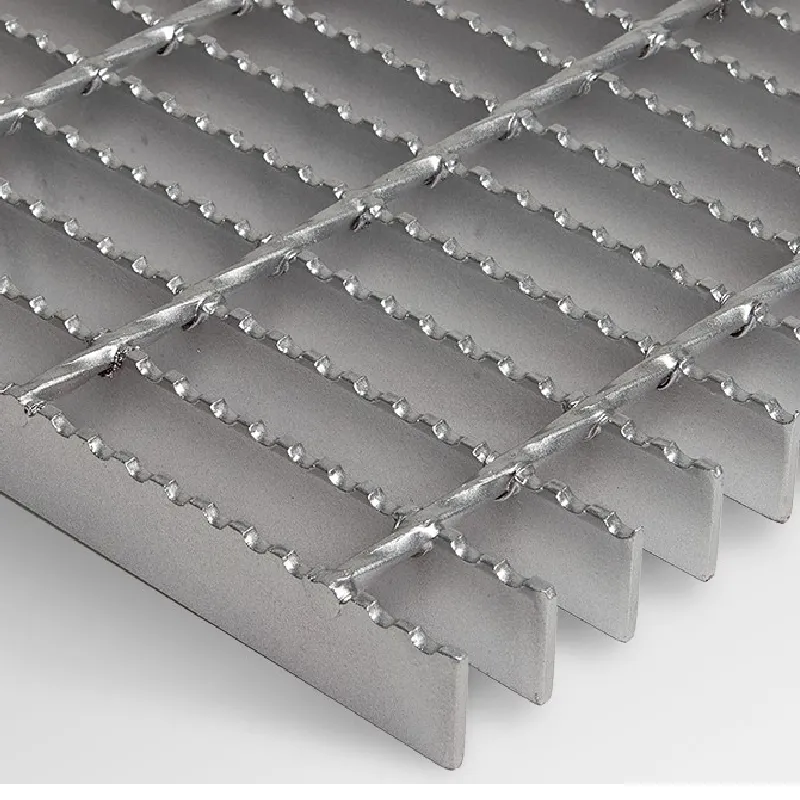

The Versatility of Steel Walkway GratingNewsAug.07,2025

-

The Benefits of Galvanized Steel Grating for Your ProjectsNewsAug.07,2025

-

Shaker Screens: The Ultimate Solution for Your Drilling NeedsNewsAug.07,2025

-

Perimeter Safety Net: An Essential Solution for Helipad SafetyNewsAug.07,2025

-

Enhance Safety and Efficiency with Steel Walkway GratingNewsAug.07,2025

-

Discover Exceptional Steel Grating for SaleNewsAug.07,2025