- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

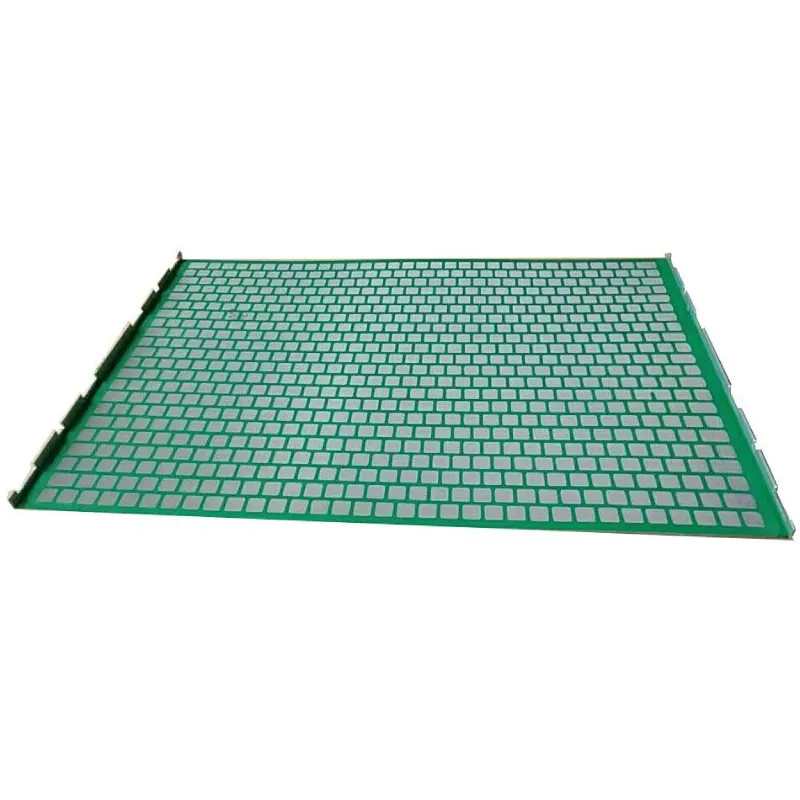

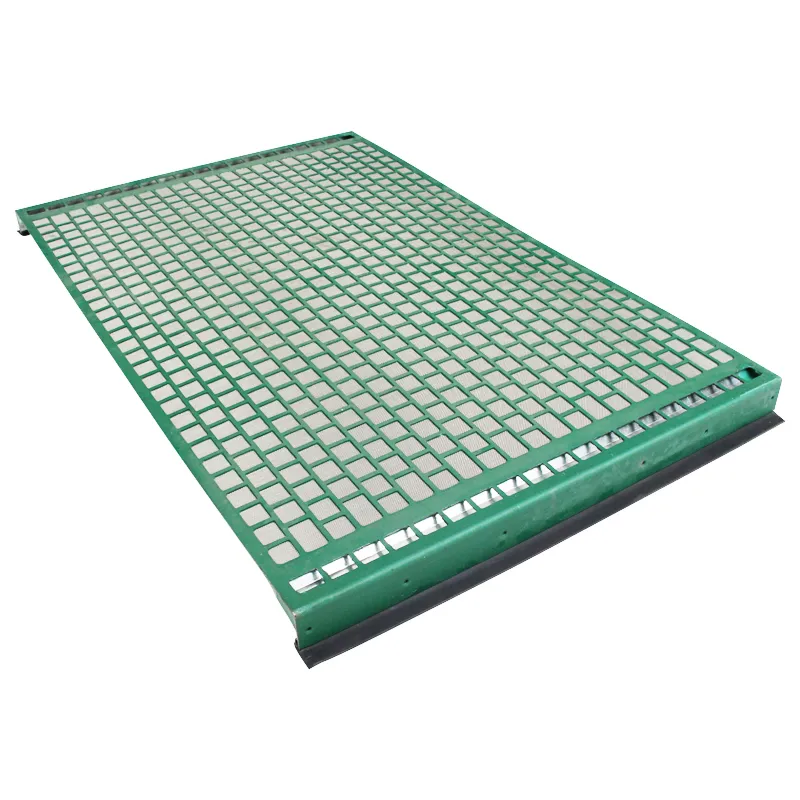

Premium Shale Shaker Screens for Efficient Drilling Filtration

Understanding the Critical Role of Shale Shaker Screens in Modern Drilling

In the intricate world of oil and gas exploration, efficient solid control is paramount for operational success, environmental compliance, and cost-effectiveness. At the heart of this process lies the shale shaker screen, a vital component designed to separate drill cuttings from valuable drilling fluid, or mud. This initial phase of solid-liquid separation significantly impacts drilling efficiency, drilling fluid longevity, and overall operational expenditure. The advent of advanced drilling techniques, such as horizontal drilling and hydraulic fracturing, has amplified the demand for high-performance screens capable of handling increased flow rates and finer particle separation. Modern screens must offer superior filtration efficiency, extended service life, and robust construction to withstand the harsh conditions encountered on drilling rigs. The continuous evolution of screen technology aims to reduce mud losses, minimize waste disposal volumes, and enhance drilling penetration rates, making the selection of the right screen a critical strategic decision for drilling operators globally.

The market for shale shaker screen technology is experiencing robust growth, driven by increasing global energy demands and the continuous innovation in drilling fluid management. Industry trends point towards a greater adoption of composite screens, known for their lighter weight, improved flow capacity, and extended operational life compared to traditional metal screens. Furthermore, there's a growing emphasis on screens with optimized shale shaker screen mesh configurations, designed to achieve higher conductivity and finer cut points without sacrificing throughput. This technological push is supported by a global commitment to environmental responsibility, as more efficient solid control directly contributes to reducing the carbon footprint of drilling operations. As drilling activities expand into more challenging geological formations and remote areas, the reliability and performance of these screens become even more crucial, underscoring their irreplaceable role in the modern energy sector.

Technical Specifications and Performance Parameters

Choosing the right shale shaker screen involves a deep understanding of its technical specifications and how these parameters translate into real-world performance. Key metrics include mesh size (measured in microns or API mesh numbers), screen area, non-blanked screen area (NSA), conductance, and cut point. The API RP 13C standard provides a standardized method for evaluating screen performance, ensuring comparability across different manufacturers. Higher conductance values typically indicate better fluid flow through the screen, while a finer cut point signifies superior separation efficiency, leading to cleaner drilling fluid. The mechanical integrity, material composition (often stainless steel or composite frames with multi-layered mesh), and frame design (e.g., Hook Strip Flat Screen) also play a pivotal role in determining the screen's durability and resistance to wear and tear in high-vibration, abrasive environments.

Typical Shale Shaker Screen Parameters (Hook Strip Flat Screen)

| Parameter | Description | Typical Range/Value |

|---|---|---|

| API Mesh Number | Indicates mesh fineness based on API RP 13C. | 20 to 325 |

| Cut Point (D100) | Particle size (in microns) at which 100% of particles are retained. | 74 to 800 microns |

| Non-Blanked Screen Area (NSA) | Effective open area for fluid flow, crucial for capacity. | 0.5 to 1.5 m² (depending on screen size) |

| Conductance (kiloDarcy) | Measure of fluid flow through the screen. | 10 to 300 kD |

| Screen Life | Expected operational hours under normal conditions. | 200 to 600+ hours |

| Applicable Industries | Primary sectors where screens are utilized. | Oil & Gas, Horizontal Directional Drilling, Mining, Water Well Drilling |

The performance of a shale shaker screen is not static; it is influenced by drilling fluid properties, flow rates, and the G-forces applied by the shaker. Optimized screens, like the Hook Strip Flat Screen, are designed to maximize throughput while maintaining efficient solids removal, thereby reducing drilling fluid losses and minimizing wear on downstream equipment. This directly translates into significant operational savings and improved drilling rates. The meticulous engineering of each screen ensures that it performs reliably under extreme conditions, upholding the highest standards of efficiency and durability required in challenging drilling environments.

Manufacturing Excellence and Quality Assurance

The production of a high-quality shale shaker screen is a complex process demanding precision and adherence to stringent quality control protocols. It typically begins with the selection of premium-grade stainless steel wire (e.g., SS304, SS316, or specialized alloys) for the mesh, or advanced composite materials for the frame. The wire mesh is often woven or perforated to specific API-compliant patterns and then precisely cut. Frame fabrication follows, utilizing processes such as advanced welding for steel frames or injection molding for composite frames, ensuring structural integrity. For the Hook Strip Flat Screen, the tensioning of the mesh onto the frame is a critical step, often involving specialized machinery to ensure uniform tension and prevent premature blinding or tearing. Each screen undergoes rigorous inspection at various stages.

Post-assembly, critical quality checks are performed, including visual inspection for defects, dimensional verification, and sometimes, even dynamic testing to simulate shaker vibrations. Compliance with international standards such as ISO 9001 for quality management and API RP 13C for screen testing is non-negotiable for reputable manufacturers. The manufacturing process often incorporates CNC machining for frame components to ensure precise fit and finish, contributing to the screen's longevity and performance. The commitment to these high standards ensures that each shale shaker screen delivered exhibits superior wear resistance, optimal filtration capabilities, and a prolonged service life, ultimately reducing operational downtime and maintenance costs in applications across petrochemical, metallurgy, and water treatment industries.

Technical Advantages and Application Scenarios

The technical advantages of advanced shale shaker screen designs are multifaceted, directly impacting operational efficiency and environmental footprint. Screens like the Hook Strip Flat Screen offer enhanced flow capacity, allowing for higher processing volumes of drilling fluid, which is crucial in high-rate drilling operations. Their optimized shale shaker screen mesh layers provide superior solids separation, leading to cleaner drilling mud that can be recirculated, minimizing mud losses and the need for fresh fluid. This translates into significant cost savings in mud chemicals and disposal fees. Furthermore, the robust construction ensures exceptional durability and resistance to blinding, a common issue where fine particles clog the mesh, reducing screen efficiency.

In various application scenarios, the benefits of high-performance screens are evident. In conventional drilling, they efficiently remove coarser cuttings, protecting downstream equipment like desanders and desilters. For challenging horizontal drilling and deep-well operations, where formation stability and precise mud weight control are critical, advanced screens ensure the removal of very fine solids, maintaining optimal rheological properties of the drilling fluid. In mining and tunneling, these screens are crucial for separating rock particles from drilling slurries, while in environmental applications, they aid in waste water treatment by filtering out suspended solids. Their corrosion resistance makes them suitable for use with various drilling fluid chemistries, including oil-based, water-based, and synthetic-based muds, showcasing their versatility and adaptability across diverse industrial needs.

Manufacturer Comparison and Customization Solutions

The global market for shale shaker screen products features a diverse range of manufacturers, each with unique strengths. When evaluating potential suppliers, key factors extend beyond just the shale shaker screen price. It's crucial to assess their adherence to API standards, quality of raw materials, manufacturing consistency, and post-sales support. Leading manufacturers often differentiate themselves through superior R&D capabilities, offering innovative designs like composite frames, advanced multi-layer mesh configurations, and custom sizes tailored to specific shaker models. The service life, resistance to blinding, and overall efficiency are significant differentiators that can impact long-term operational costs.

For specialized drilling projects or unique shaker equipment, customization solutions offered by a dedicated shale shaker screen factory become invaluable. This might involve screens with specific mesh patterns for ultra-fine separation, custom dimensions to fit non-standard shaker models, or specialized materials for corrosive environments. Experienced manufacturers like us, with years of expertise in the field, possess the technical know-how and manufacturing flexibility to provide bespoke solutions that optimize solid control systems for maximum performance and efficiency. Our commitment to understanding client-specific challenges allows us to engineer screens that not only meet but exceed performance expectations, contributing directly to improved drilling economics and environmental stewardship.

Client Experience and Trustworthiness

Our track record in delivering high-performance Hook Strip Flat Screens speaks volumes about our commitment to quality and client satisfaction. Over the past decade, we have supplied thousands of shale shaker screen units to drilling operations across North America, the Middle East, and Asia, supporting diverse projects from conventional oil and gas to challenging geothermal drilling. Our screens have consistently demonstrated extended operational life, often exceeding industry averages by 20-30%, leading to reduced replacement costs and minimal downtime for our clients. For instance, a recent deep-well drilling project in the Permian Basin reported a 15% reduction in mud losses attributed directly to the superior separation efficiency of our screens, translating into substantial savings on drilling fluid expenses.

Frequently Asked Questions (FAQ)

-

Q: How does your shale shaker screen improve drilling efficiency?

A: Our screens feature optimized shale shaker screen mesh designs that maximize non-blanked screen area and conductance, allowing for higher fluid throughput while maintaining a fine cut point. This efficiently removes solids, preserving mud properties, reducing wear on pumps, and ultimately increasing penetration rates.

-

Q: What is the typical delivery timeframe for large orders?

A: For standard orders, our delivery cycle typically ranges from 7 to 14 business days, depending on the volume and destination. For large-scale customized orders, we provide a detailed timeline during the quotation process, often ranging from 3 to 5 weeks to ensure rigorous quality control.

-

Q: What warranty do you offer on your Hook Strip Flat Screens?

A: We offer a comprehensive 6-month warranty against manufacturing defects and material failures under normal operating conditions. Our commitment extends to robust customer support, ensuring quick resolution of any performance concerns and providing expert technical assistance whenever needed.

Our dedication to quality is underscored by our ISO 9001 certification and strict adherence to API RP 13C standards, ensuring every Hook Strip Flat Screen meets the highest industry benchmarks. We provide comprehensive technical support, from initial consultation to post-installation guidance, ensuring optimal performance and maximum return on investment for our clients. This holistic approach, combined with transparent pricing and reliable delivery, solidifies our position as a trusted partner in the solid control industry.

References

- American Petroleum Institute. (2020). Recommended Practice 13C: Drilling Fluid Processing Equipment Evaluation.

- International Organization for Standardization. (2015). ISO 9001: Quality management systems – Requirements.

- Oilfield Review. (2018). Innovations in Solid-Control Technology for Enhanced Drilling Efficiency. Schlumberger.

- Journal of Petroleum Technology. (2019). Advancements in Shale Shaker Screen Design for Environmental Compliance. Society of Petroleum Engineers.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025