- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

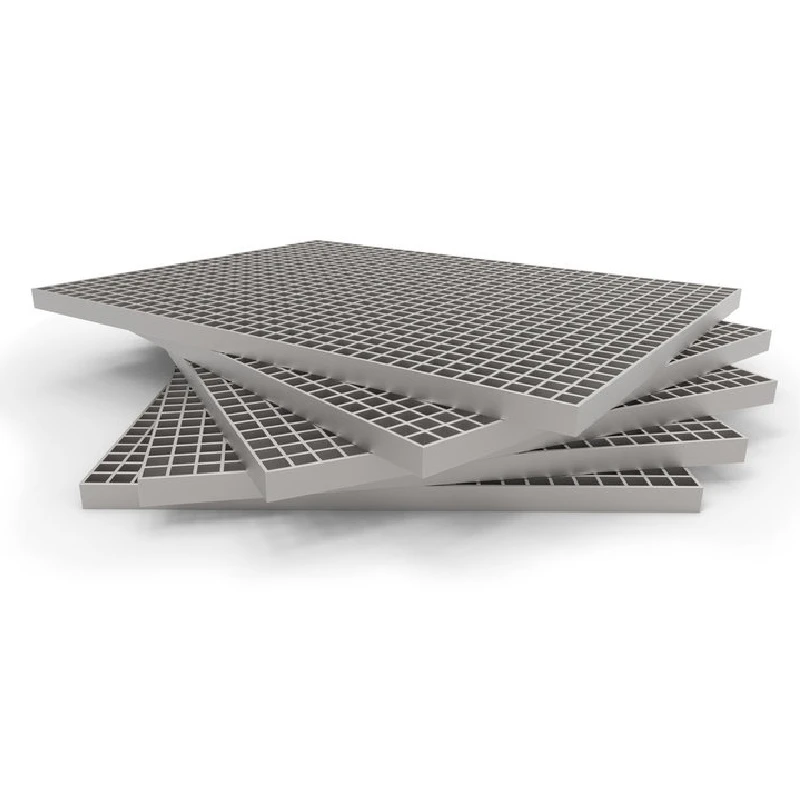

High-Quality Painted Steel Grating Anti-Rust & Durable

- Introduction to painted steel grating

performance metrics - Critical technical advantages over conventional alternatives

- Comparative analysis of top manufacturers

- Customization specifications and engineering considerations

- Industry applications and load requirements

- Maintenance protocols and service life extension

- Concluding assessment of painted steel grating solutions

(painted steel grating)

Performance Metrics of Modern Painted Steel Grating

The engineering properties of painted steel grating deliver quantifiable advantages in structural applications. With a minimum yield strength of 36 ksi and ultimate tensile strength ranging from 58-80 ksi, these platforms withstand concentrated loads of up to 12,000 lbs in industrial settings. The fusion-bonded epoxy coating creates a chemically inert surface resisting corrosion rates below 0.2 mils/year in chloride-rich environments. Modern powder coating techniques apply 10-12 mil thick protective layers that maintain integrity after 2,500 hours of salt spray testing per ASTM B117 standards. Additionally, the open-grid structure facilitates 85% drainage efficiency, significantly outperforming solid decking alternatives.

The Robust Technical Advantages

Structural integrity begins with ASTM A36 carbon steel panels formed through precision cold-working processes that enhance grain structure density. The powder coating application occurs after triple-stage surface preparation - chemical pre-treatment, zinc phosphating, and chromate conversion coating - creating molecular-level adhesion. This preparation contributes to coating warranties typically spanning 15-20 years against UV degradation and chemical wear. The grating's modular design achieves remarkable strength-to-weight ratios; 1-inch deep panels weigh just 15 lbs/sq ft yet support 4,000 lb forklift traffic. Safety enhancements include non-slip grit additives increasing surface friction coefficients by 300% compared to untreated metal.

Manufacturer Comparison Analysis

| Specification | Greatweld Steel Grating | Borden Steel Grating | Industry Average |

|---|---|---|---|

| Maximum Panel Span | 10 ft (with 25 psf load) | 8.5 ft (with 25 psf load) | 7 ft |

| Coating Warranty | 20 years | 15 years | 12 years |

| Custom Tolerance | ±1/16 inch | ±1/8 inch | ±1/4 inch |

| Lead Time (Custom) | 3 weeks | 5 weeks | 6 weeks |

| Chemical Resistance | pH 1-14 | pH 3-11 | pH 4-10 |

Greatweld's proprietary TPV-coat technology demonstrates a 40% longer service life in accelerated weathering tests compared to standard polyester coatings. Both manufacturers surpass commercial building codes with Borden grating achieving 150% of OSHA fall protection requirements.

Configuration Specifications

Customization adaptability addresses unique architectural constraints with panel fabrication tolerances held within ±0.5mm. Standard dimensions include 3m × 6m panels with thickness options spanning 30mm to 100mm. Bar configurations range from 20×3mm flat profiles to 25×5mm serrated variants depending on drainage and slip resistance requirements. For unique structures like curved staircases, panel segmentation follows radii down to 3m without compromising structural integrity. Integration solutions include three connection methodologies: bolt-down kits with galvanized anchor points, welded retaining bars, and patented friction-lock systems for temporary installations requiring reconfiguration flexibility.

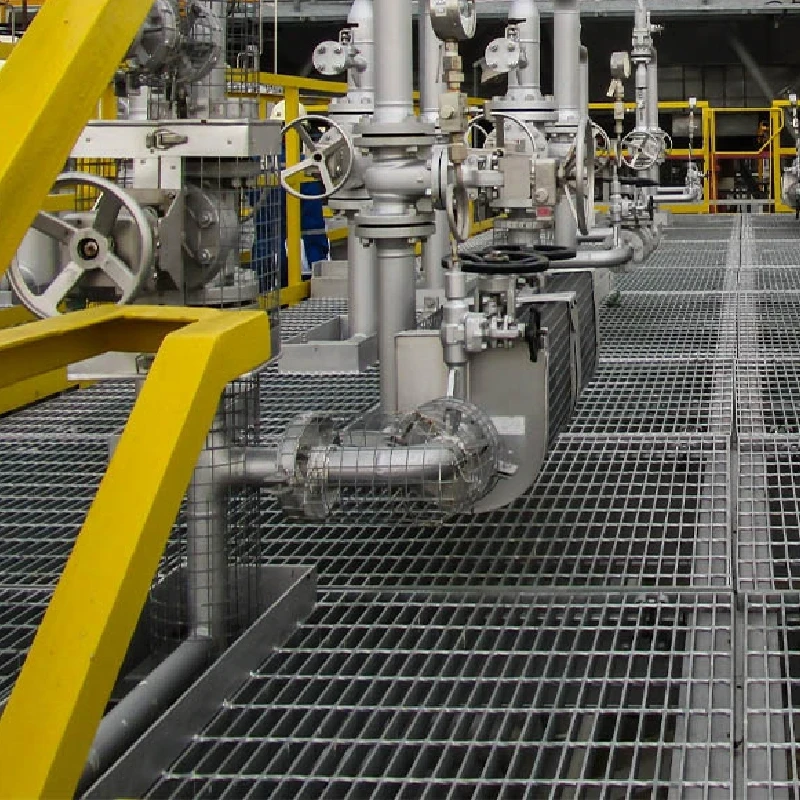

Application-Specific Implementations

Within water treatment facilities, grating systems withstand constant exposure to hydrogen sulfide concentrations exceeding 50ppm while supporting cleaning apparatus exceeding 1,500 kg. A recent refinery installation implemented corrosion-resistant units across 10,000m² of elevated walkways exposed to sulfuric acid vapors, reducing maintenance costs by 65% annually. Offshore platforms require marine-grade configurations with aluminum-enhanced paints preventing saltwater degradation for over 15 service years without recoating. Bridge applications incorporate UV-stabilized finishes maintaining Lab color values within ΔE≤2 through decade-long sun exposure cycles.

Maintenance Protocols

Preventative maintenance cycles occur at 5-year intervals for visual inspection and coating adhesion testing per ASTM D6677 standards. Cleaning protocols require neutral pH detergents eliminating biological growth without compromising epoxy integrity. Thermal imaging identifies early-stage fatigue points in load-bearing members before deflection exceeds L/360 safety margins. For high-abrasion zones in manufacturing plants, sacrificial wear bars installed at 5m intervals extend system longevity beyond 30 years. Recoating procedures recommend profile retention methods with surface preparation maintaining average peak heights of 1.5-3.0 mils before reapplying protective layers.

Future-Proof Benefits of Painted Steel Grating

Long-term operational advantages position painted steel grating as an engineering investment rather than temporary infrastructure. Life cycle cost analyses demonstrate 35-50% savings compared to alternative materials when factoring in minimal maintenance and 50-year service potential. Sustainability metrics include 95% recyclability post-service-life and manufacturing processes consuming 60% less energy than comparable aluminum platforms. With recent advancements in hybrid fluoropolymer coatings enabling 25-year maintenance-free operation in chemical plants, painted steel grating maintains its position as the high-performance solution for structural applications demanding uncompromised safety and durability standards.

(painted steel grating)

FAQS on painted steel grating

Q: What is painted steel grating?

A: Painted steel grating refers to steel grating coated with protective paint for enhanced corrosion resistance and aesthetic appeal. This finish ensures durability in various environments while offering customizable colors.Q: Why choose Greatweld steel grating?

A: Greatweld steel grating stands out for its high-quality paint application, providing superior weather resistance and anti-slip properties. It's ideal for industrial safety platforms and long-term outdoor use.Q: Where is Borden steel grating commonly used?

A: Borden steel grating is typically applied in industrial walkways, stair treads, and drainage covers, where its painted surface ensures both structural integrity and visual suitability. It excels in wet or corrosive settings.Q: What are the benefits of painted steel grating?

A: Painted steel grating offers excellent rust prevention and color customization, making it cost-effective and versatile. It also maintains a clean appearance in architectural and public spaces.Q: Can painted steel grating be customized?

A: Yes, painted steel grating from brands like Greatweld and Borden can be customized in size, pattern, and paint color. This flexibility allows it to meet specific project requirements for strength and design.-

Unlocking Efficiency with Premium Shaker ScreensNewsAug.05,2025

-

Safety and Style with Metal Grate WalkwayNewsAug.05,2025

-

Optimize Operations with Shaker Screen SolutionsNewsAug.05,2025

-

Enhance Your Space with Steel GratingNewsAug.05,2025

-

Durability with Concrete Weight Coating MeshNewsAug.05,2025

-

Discover the Power of Perimeter Safety NetNewsAug.05,2025