- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Mar . 04, 2025 09:44

Back to list

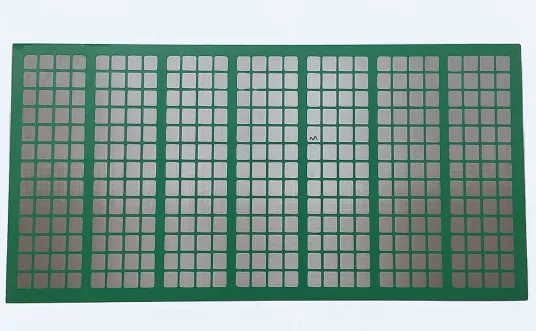

Offshore Pipeline Counterweight Welded Wire Mesh

CWC pipe coating, a crucial component for enhancing the durability and performance of pipelines, stands at the intersection of engineering proficiency and cutting-edge materials science. This process involves the application of a concrete weight coating to submarine pipelines, a method renowned for its ability to provide both protection and stability against harsh underwater conditions.

When discussing authority within the pipeline coating industry, companies specializing in CWC pipe coatings often rely on a deep well of research and development. It’s not uncommon for these authorities to spend years refining their concrete mixtures and application techniques to align with the latest environmental regulations and technological advancements. Leading firms usually operate state-of-the-art laboratory facilities, conducting rigorous tests to ensure that their products exceed the expectations of pipeline operators and adhere to international standards. Trustworthiness remains the cornerstone of CWC pipe coating services. Given the high stakes involved in underwater pipeline operations, stakeholders demand transparency and accountability from CWC providers. Companies build trust by providing detailed case studies, testimonials from previous clients, and compliance certifications that validate their coatings' efficacy. Regular audits, quality checks, and third-party verifications further substantiate their claims, reinforcing their reputation as reliable partners in the preservation of subsea infrastructure. In conclusion, CWC pipe coating is indispensable for the protection and efficacy of underwater pipelines. With its proven track record of enhancing pipeline durability and reducing long-term costs, its implementation is guided by expert techs who excel in precision and consistency. The ongoing innovation and commitment to quality by leading authorities in the field reinforce the credibility and necessity of this protective technology. Stakeholders in the oil, gas, and marine construction industries can rely on CWC pipe coating, knowing it’s a trusted solution grounded in experience, expertise, authoritative research, and unwavering trustworthiness.

When discussing authority within the pipeline coating industry, companies specializing in CWC pipe coatings often rely on a deep well of research and development. It’s not uncommon for these authorities to spend years refining their concrete mixtures and application techniques to align with the latest environmental regulations and technological advancements. Leading firms usually operate state-of-the-art laboratory facilities, conducting rigorous tests to ensure that their products exceed the expectations of pipeline operators and adhere to international standards. Trustworthiness remains the cornerstone of CWC pipe coating services. Given the high stakes involved in underwater pipeline operations, stakeholders demand transparency and accountability from CWC providers. Companies build trust by providing detailed case studies, testimonials from previous clients, and compliance certifications that validate their coatings' efficacy. Regular audits, quality checks, and third-party verifications further substantiate their claims, reinforcing their reputation as reliable partners in the preservation of subsea infrastructure. In conclusion, CWC pipe coating is indispensable for the protection and efficacy of underwater pipelines. With its proven track record of enhancing pipeline durability and reducing long-term costs, its implementation is guided by expert techs who excel in precision and consistency. The ongoing innovation and commitment to quality by leading authorities in the field reinforce the credibility and necessity of this protective technology. Stakeholders in the oil, gas, and marine construction industries can rely on CWC pipe coating, knowing it’s a trusted solution grounded in experience, expertise, authoritative research, and unwavering trustworthiness.

Share

Prev:

Next:

Latest news

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025