- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

bar grating span

Exploring Bar Grating Span A Comprehensive Overview

Bar grating, a critical component in various engineering and architectural applications, serves multiple purposes ranging from safety to utility. This article delves into the concept of bar grating span, examining its significance, design considerations, and applications across different industries.

What is Bar Grating?

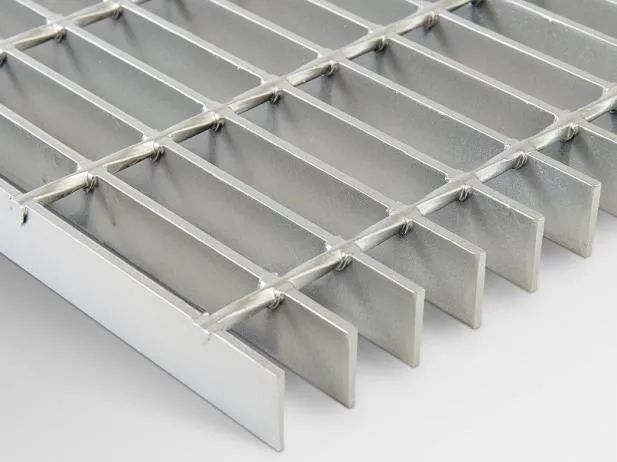

Bar grating is a type of flooring material made up of standardized, closely spaced bars that are welded or forged together. The design allows for the free flow of air, light, and liquids while providing a stable walking surface. Bar grating is typically made from materials such as steel, aluminum, and fiberglass. Its unique structural properties make it ideal for use in industrial facilities, commercial buildings, and infrastructure projects.

Understanding Bar Grating Span

The 'span' of bar grating refers to the distance between two support structures that hold up the grates. The span is critical for determining how much load the grating can support without warping or collapsing. Properly calculating the span is essential to ensure safety and durability. Incorrect span calculations can lead to structural failures, resulting in costly repairs and potential hazards.

Factors Affecting Bar Grating Span

Several factors influence the bar grating span, including

1. Load Requirements The span must be designed to support the anticipated load. This includes static loads (such as equipment or personnel) and dynamic loads (such as moving vehicles). Understanding the load requirements is essential for ensuring that the grating meets safety standards.

2. Material Properties Different materials have varying strengths and durability. For instance, steel grating typically has higher load-bearing capacity compared to fiberglass. The choice of material will affect the maximum span permissible.

3. Grating Type Bar grating comes in various designs, including welded, swaged, and interlocking gratings. Each type has distinct advantages and limitations regarding span capabilities.

4. Environmental Factors Grating exposed to harsh environmental conditions (corrosive chemicals, extreme temperatures, etc.) may require special design considerations that affect span.

bar grating span

5. Support Configuration The arrangement and type of supports (beams, columns, or concrete) also play a role in determining how far apart the supports can be placed without compromising the integrity of the grating.

Design Considerations

When designing bar grating spans, engineers typically utilize standardized loading tables to determine safe span distances based on material and load conditions. These tables consider various loading conditions and provide recommended span limits for different grating types. Furthermore, factors such as deflection limits and safety factors are considered during the design phase to ensure compliance with building codes and regulations.

Applications of Bar Grating

Bar grating is widely used across various industries. Some common applications include

- Walkways and Platforms In manufacturing plants, bar grating provides a safe, slip-resistant surface for pedestrians and workers, allowing them to navigate around machinery and hazardous areas.

- Drainage Systems Bar grating is often employed in drainage applications to cover trenches and openings while allowing water and debris to flow freely.

- Stair Treads and Ladders The slip-resistant nature of grating makes it an ideal choice for stair treads and ladders in industrial and commercial settings.

- Parking Structures Grating can support vehicular loads in parking garages while providing ventilation and light penetration.

Conclusion

Bar grating span is a crucial consideration within the design and application of this versatile material. Understanding the factors that affect span and adhering to proper design principles ensures the safety and functionality of bar grating in various applications. Whether used in walkways, drainage systems, or structural supports, the importance of carefully calculated spans cannot be overstated. As industries continue to evolve, so too will the innovations in bar grating design, promising enhanced safety and efficiency in the built environment.

-

Welded Steel Bar Grating: The Strongest Choice for Industrial FlooringNewsMay.21,2025

-

Steel Grating for Sale: The Ultimate Anti-Slip SolutionNewsMay.21,2025

-

Steel Frame Shaker Screens: Unmatched Durability for Demanding OperationsNewsMay.21,2025

-

Shaker Screens: Your Ultimate Solution for Oil & Gas FiltrationNewsMay.21,2025

-

Press Locked Steel Grating: The Smarter Choice for Heavy-Duty FlooringNewsMay.21,2025

-

Helicopter Deck Safety Nets: Protect Your Crew and EquipmentNewsMay.21,2025