- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 02, 2025 03:29

Back to list

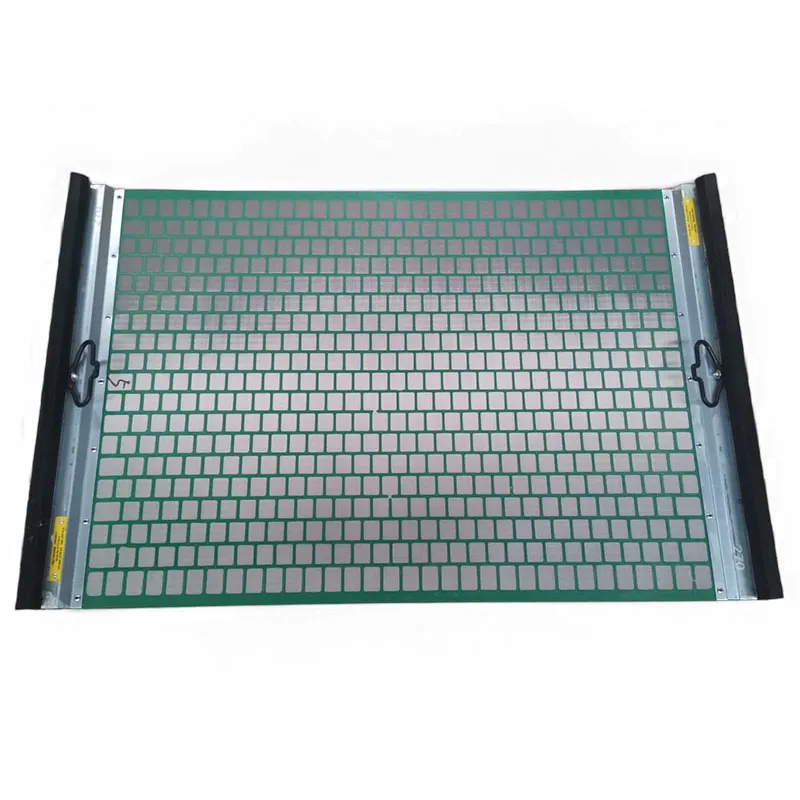

metal grating for sale

Ensuring workplace safety often hinges on selecting the right materials to minimize hazards, especially where slippery surfaces are involved. Non-slip metal grating is a paramount product in environments where both safety and durability are non-negotiable. This functional product not only contributes to preventing accidents but also withstands rigorous conditions, making it a preferred choice in industries ranging from manufacturing to transportation.

Trustworthiness in product selection for safety solutions cannot be overemphasized. Non-slip metal grating provides not just peace of mind but also demonstrable satisfaction to health and safety officers and facility managers who prioritize accident prevention. Testimonials and case studies from varied industries bear witness to the numerous instances where these gratings have significantly reduced the likelihood of workplace incidents. Installations of non-slip metal gratings in warehouses, production facilities, and public infrastructure have consistently resulted in lower accident rates and boosted worker confidence. Making an informed choice about non-slip metal grating requires understanding both the technical specifications and the operational demands of your environment. Consulting with experts who specialize in industrial safety can help tailor solutions to specific needs. For example, choosing between pressed, welded, or swaged grating may depend on the application requirements, such as load types and environmental conditions. In conclusion, non-slip metal grating stands out as a first-rate safety solution that combines expert engineering, recognized authority, and trustworthy performance. Its implementation not only enhances safety protocols but, more importantly, it fortifies the commitment to creating workplaces that prioritize the welfare of their workers. As industries continue to evolve and safety standards become even more stringent, the integration of such reliable products will remain indispensable. Through the thoughtful selection and application of non-slip metal grating, businesses can foster environments that not only meet but exceed contemporary safety expectations.

Trustworthiness in product selection for safety solutions cannot be overemphasized. Non-slip metal grating provides not just peace of mind but also demonstrable satisfaction to health and safety officers and facility managers who prioritize accident prevention. Testimonials and case studies from varied industries bear witness to the numerous instances where these gratings have significantly reduced the likelihood of workplace incidents. Installations of non-slip metal gratings in warehouses, production facilities, and public infrastructure have consistently resulted in lower accident rates and boosted worker confidence. Making an informed choice about non-slip metal grating requires understanding both the technical specifications and the operational demands of your environment. Consulting with experts who specialize in industrial safety can help tailor solutions to specific needs. For example, choosing between pressed, welded, or swaged grating may depend on the application requirements, such as load types and environmental conditions. In conclusion, non-slip metal grating stands out as a first-rate safety solution that combines expert engineering, recognized authority, and trustworthy performance. Its implementation not only enhances safety protocols but, more importantly, it fortifies the commitment to creating workplaces that prioritize the welfare of their workers. As industries continue to evolve and safety standards become even more stringent, the integration of such reliable products will remain indispensable. Through the thoughtful selection and application of non-slip metal grating, businesses can foster environments that not only meet but exceed contemporary safety expectations.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025