- Zona industri, Selatan Kota Anping, Hengshui, Hebei, Cina.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  Bahasa inggris

Bahasa inggris  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Bahasa inggris

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Helideck Safety Nets: Your First Line of Defense

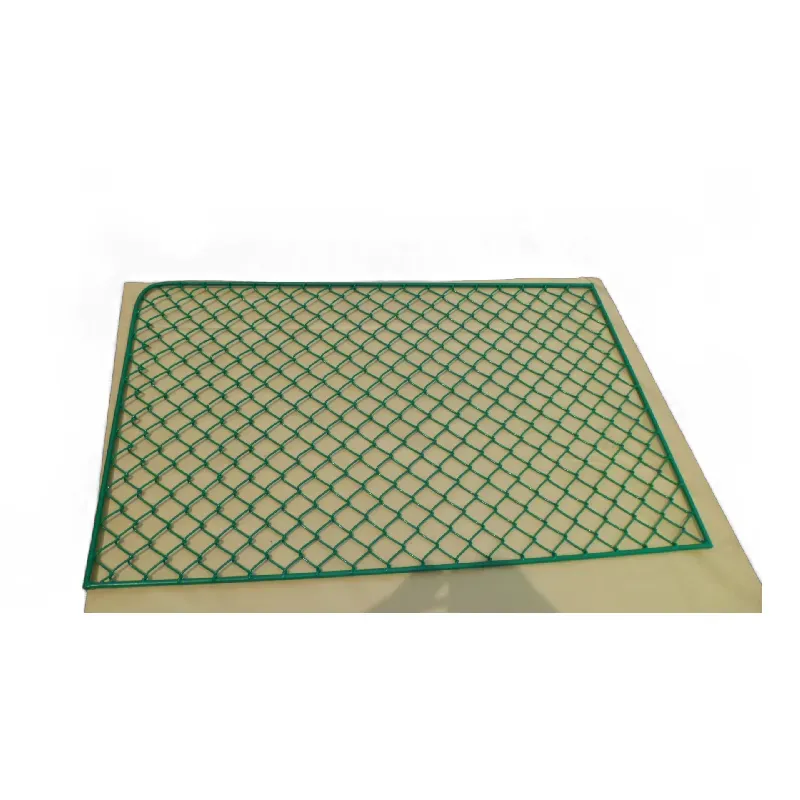

When it comes to offshore and elevated helideck operations, safety isn't just a priority—it's a necessity. That's where helideck safety net systems come into play. Our premium helideck netting solutions, including specialized helideck perimeter net installations, provide the ultimate protection against falls and equipment loss. Designed as essential helideck perimeter safety nets, these surrounded structures of helicopter landing decks serve one critical purpose: preventing equipment and personnel from falling. Whether you're managing an offshore rig, hospital rooftop landing pad, or any elevated helideck, our safety nets deliver unmatched protection and peace of mind.

Why Helideck Safety Net Systems Are Non-Negotiable

Every helicopter landing operation carries inherent risks, making helideck safety net installations absolutely vital. These specialized barrier systems act as the last line of defense, catching anything—or anyone—that might slip off the deck's edge. Unlike standard railings that can obstruct operations, our helideck netting provides unobtrusive yet incredibly strong protection. The helideck perimeter net is engineered to withstand extreme weather conditions while maintaining flexibility to absorb impacts. For facilities where every square foot matters, these safety solutions offer maximum protection with minimal footprint. Remember: when it comes to elevated operations, prevention is always better than reaction.

The Critical Role of Helideck Perimeter Safety Nets

The helideck perimeter safety nets serve as the surrounded structures of helicopter landing decks that many operators don't think about—until they're needed. Designed specifically to prevent equipment and personnel from falling, these nets are constructed from ultra-strong, UV-resistant materials that won't degrade in harsh marine environments. Unlike solid barriers that can create dangerous wind patterns, our helideck netting allows for proper airflow while stopping falls cold. The modular design means easy installation and replacement of sections if needed, with all components meeting strict aviation safety standards. For offshore installations where rescue operations are complex, these nets aren't just equipment—they're potentially life-saving infrastructure.

Custom Helideck Netting Solutions for Every Application

One size doesn't fit all when it comes to helideck safety net requirements. That's why we offer fully customizable helideck perimeter net systems tailored to your specific deck dimensions and operational needs. Our engineers consider factors like maximum potential load, frequent wind directions, and deck usage patterns when designing your helideck perimeter safety nets. Special attachments allow for quick deployment during emergencies while maintaining a low profile during normal operations. The high-visibility coloring of our helideck netting serves dual purposes: it marks the deck edge clearly for personnel while maintaining the net's presence in pilots' peripheral vision during approach and departure.

Maintenance and Compliance for Helideck Safety Systems

Installing helideck safety net systems is just the beginning—proper maintenance ensures they remain effective. Our helideck netting products come with clear inspection guidelines and easy-to-replace components. The helideck perimeter net materials are treated to resist saltwater corrosion, mold growth, and UV damage, dramatically extending service life in harsh environments. For compliance officers, our helideck perimeter safety nets meet all major international standards including ICAO and CAP 437 requirements. We provide complete documentation packages to simplify your safety audits and inspections. Remember: properly maintained safety nets don't just protect people—they protect your operation's reputation and bottom line too.

FAQs About Helideck Safety Nets

How often should helideck safety nets be inspected?

All helideck safety net systems require formal monthly inspections, with visual checks before each flight operation.

What weight capacity do helideck perimeter safety nets have?

Our standard helideck perimeter net systems are rated for 500kg dynamic loads, with higher capacities available.

Can the nets withstand extreme weather conditions?

Yes, our helideck netting is engineered to perform in winds exceeding 150km/h and temperatures from -40°C to 80°C.

How long does installation typically take?

Most helideck perimeter safety nets can be installed in 2-3 days with minimal disruption to operations.

Are there color options for visibility requirements?

We offer high-visibility orange, yellow, or white helideck safety net options to meet various regulatory standards.

Every helicopter operation carries enough inherent risks without adding preventable dangers. Our helideck safety net systems provide that critical last line of defense when seconds count. With customizable helideck netting solutions, compliant helideck perimeter net configurations, and ultra-durable helideck perimeter safety nets, we help you create the safest possible landing environment. These surrounded structures of helicopter landing decks do more than meet regulations—they save lives and equipment. Visit our website today to request your custom safety evaluation—because when it comes to helideck operations, there's no such thing as being too safe. Protect your people, protect your assets, and protect your peace of mind with professional-grade safety netting solutions.

-

Welded Steel Grating: The Strong Foundation for Industrial SafetyBeritaJul.16,2025

-

Strong and Safe: Swaged Grating SolutionsBeritaJul.16,2025

-

Smart Choice For Industrial Safety MeshBeritaJul.16,2025

-

Press-Locked Steel Grating: The Ultimate in Strength and SafetyBeritaJul.16,2025

-

Keep Worksites Safer With Practical NettingBeritaJul.16,2025