- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Welded Wire Mesh Solutions for Offshore Pipeline Counterweights and Structural Support Systems

Offshore Pipeline Counterweight The Role of Welded Wire Mesh

The offshore oil and gas industry relies heavily on pipelines for the transportation of hydrocarbons from remote locations to processing facilities and refineries. Among various engineering innovations, the use of counterweights in offshore pipeline installations is critical to ensuring stability and integrity under harsh marine conditions. A significant component of this counterweight system is welded wire mesh, which serves both structural and functional purposes.

Understanding Offshore Pipelines

Offshore pipelines are typically submerged beneath the seabed, carrying materials such as oil, natural gas, and water. The harsh marine environment presents a multitude of challenges, including shifting seabeds, water currents, and potential environmental impacts. To mitigate these challenges, counterweights are often added to pipelines, particularly in areas with unstable soil or varying underwater topography. These counterweights help maintain the desired elevation of pipelines and prevent buoyancy issues that could lead to structural failures.

The Importance of Counterweights

Counterweights play a crucial role in the anchoring of pipelines on the seabed. Without adequate ballast, pipelines may float or shift, leading to leaks or ruptures that could have catastrophic environmental consequences. The primary function of these counterweights is to ensure that pipelines remain in place despite the dynamic conditions of the marine environment. They provide stability and support, allowing for safer operations and prolonged service life of the pipelines.

Welded Wire Mesh A Viable Solution

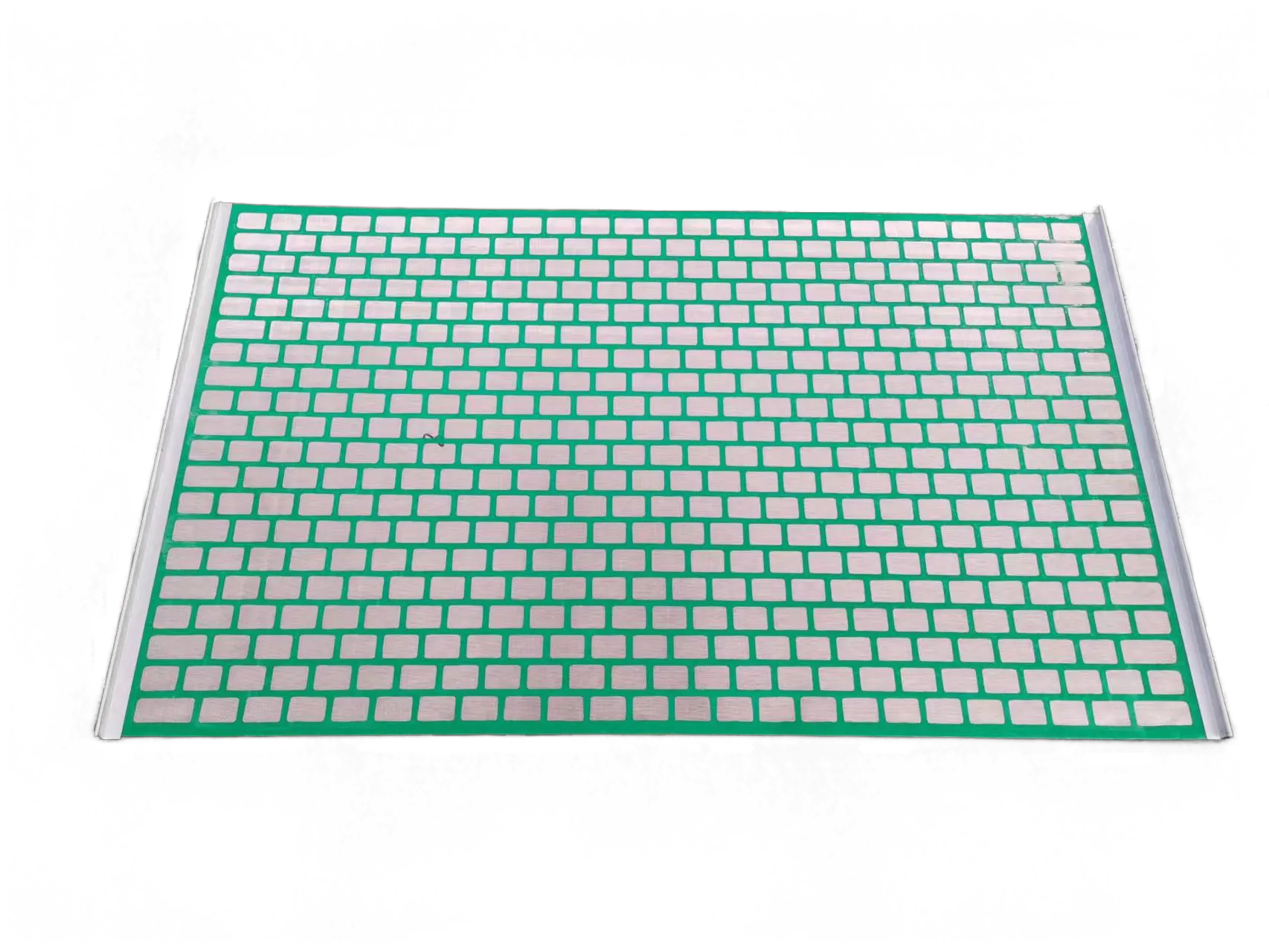

Welded wire mesh has emerged as a reliable choice for constructing counterweights in offshore pipeline applications. This material is made by welding together steel wires to form a grid-like structure. Here are several reasons why welded wire mesh is advantageous

1. Strength and Durability Welded wire mesh is known for its high tensile strength and resilience against corrosion, particularly when coated with protective materials like galvanization or polyethylene. This durability is essential for withstanding harsh marine conditions, including saltwater exposure.

offshore pipeline counterweight welded wire mesh

2. Customizability The versatility of welded wire mesh allows for the customization of sizes and configurations to meet specific engineering requirements. This adaptability is critical in offshore environments where pipeline specifications can vary widely based on location and deployment conditions.

3. Weight Distribution The design of welded wire mesh aids in the even distribution of weight. This characteristic ensures that the counterweight maintains a stable position, further preventing any potential pipeline movement.

4. Cost-Effectiveness Compared to other materials, welded wire mesh can be economically beneficial. It requires less material for construction due to its efficient design while maintaining structural integrity, which helps in reducing overall costs associated with installation and maintenance.

5. Easy Installation The lightweight nature of welded wire mesh facilitates easier handling and installation, essential factors in offshore construction where complex logistics can pose challenges.

Environmental Considerations

In today’s environmentally conscious world, the use of welded wire mesh also aligns with sustainable practices. The material is recyclable, meaning that at the end of its service life, it can be repurposed, reducing waste and environmental impact. Moreover, the structural integrity provided by these mesh counterweights aids in preventing leaks and spills, thereby protecting marine ecosystems.

Conclusion

Welded wire mesh serves as a crucial component in the development of offshore pipeline counterweight systems. Its unique properties—strength, durability, customizability, and cost-effectiveness—make it an ideal solution for enhancing the stability of pipelines in challenging underwater environments. As the demand for offshore energy resources continues to grow, innovations like welded wire mesh will play an essential role in ensuring the safety and reliability of these vital transportation systems.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025