- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Մրտ . 05, 2025 01:25

Back to list

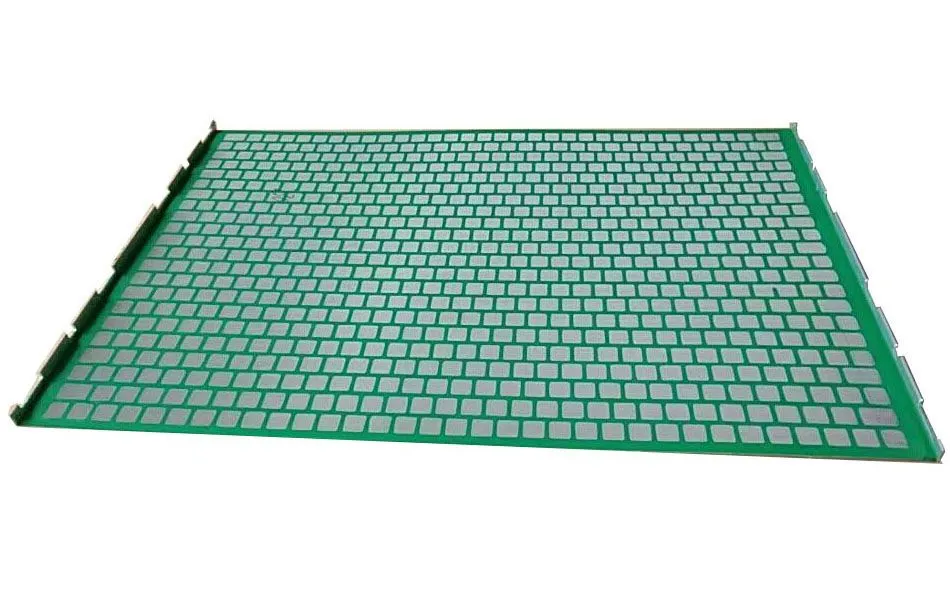

11w4 grating

When it comes to engineering and architectural breakthroughs, few components are as essential yet underrated as grating systems. Among these, the “11w4 grating” stands out, offering an impressive synthesis of functionality and versatility. Typically utilized in industrial environments, this particular grating delivers unique features that enhance operational efficiency, safety, and durability.

Trustworthiness in the industrial components market is paramount, and the 11w4 grating garners this through its proven track record. Institutions ranging from small businesses to large corporations have relied on this grating for decades, rendering it a staple in their infrastructural inventories. Users report high satisfaction levels due to the low maintenance requirements and the product’s ability to withstand extreme pressure and heavy loads. Safety being a prime concern in any industrial setting, the 11w4 grating’s slip-resistant surface minimizes risks associated with wet or oily conditions, thus safeguarding personnel and machinery alike. In the evolving landscape of industrial requisites, what truly sets the 11w4 grating apart is its contribution to sustainable practices. According to recent advancements, grating systems using recycled materials are gaining traction, aligning with global priorities around reducing environmental impact. The 11w4 grating manufacturers have embraced this shift by offering products made from recycled metals, thus promoting sustainable building practices without sacrificing quality or performance. The plethora of applications that benefit from the 11w4 grating is expansive. Facility managers appreciate the grating’s capacity to enhance operational workflows, while engineers commend its straightforward integration into existing systems. This grating serves as a testament to the harmonious blend of innovation and tradition, offering solutions that are both cutting-edge and enduringly reliable. In summary, the 11w4 grating is not merely a structural component but a beacon of engineering excellence. It embodies the principles of Experience, Expertise, Authoritativeness, and Trustworthiness—the four pillars that any professional should consider when selecting material solutions. As industries continue to evolve, the demand for such versatile and reliable components will inevitably rise, making the 11w4 grating a critical player in future infrastructure projects. With its demonstrated excellence, it sets the benchmark for quality, performance, and sustainability, ensuring users not only meet but exceed their operational objectives.

Trustworthiness in the industrial components market is paramount, and the 11w4 grating garners this through its proven track record. Institutions ranging from small businesses to large corporations have relied on this grating for decades, rendering it a staple in their infrastructural inventories. Users report high satisfaction levels due to the low maintenance requirements and the product’s ability to withstand extreme pressure and heavy loads. Safety being a prime concern in any industrial setting, the 11w4 grating’s slip-resistant surface minimizes risks associated with wet or oily conditions, thus safeguarding personnel and machinery alike. In the evolving landscape of industrial requisites, what truly sets the 11w4 grating apart is its contribution to sustainable practices. According to recent advancements, grating systems using recycled materials are gaining traction, aligning with global priorities around reducing environmental impact. The 11w4 grating manufacturers have embraced this shift by offering products made from recycled metals, thus promoting sustainable building practices without sacrificing quality or performance. The plethora of applications that benefit from the 11w4 grating is expansive. Facility managers appreciate the grating’s capacity to enhance operational workflows, while engineers commend its straightforward integration into existing systems. This grating serves as a testament to the harmonious blend of innovation and tradition, offering solutions that are both cutting-edge and enduringly reliable. In summary, the 11w4 grating is not merely a structural component but a beacon of engineering excellence. It embodies the principles of Experience, Expertise, Authoritativeness, and Trustworthiness—the four pillars that any professional should consider when selecting material solutions. As industries continue to evolve, the demand for such versatile and reliable components will inevitably rise, making the 11w4 grating a critical player in future infrastructure projects. With its demonstrated excellence, it sets the benchmark for quality, performance, and sustainability, ensuring users not only meet but exceed their operational objectives.

Share

Prev:

Next:

Latest news

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025