- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

febr . 10, 2025 11:33

Back to list

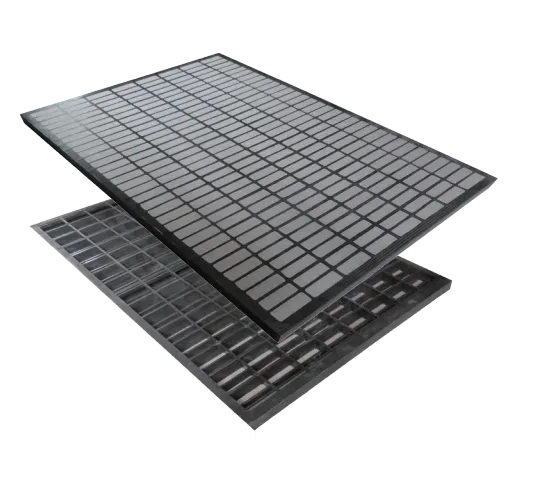

shale shaker screen mesh

Optimizing shaker screen mesh for industrial applications demands a comprehensive understanding of its design, functionality, and impact on operational efficiency. Shaker screens are a critical component in various sectors such as oil drilling, mining, and sand processing. By focusing on experience, expertise, authoritativeness, and trustworthiness, this article aims to provide unparalleled insight into the subject.

Authoritativeness is strengthened by understanding the regulatory and environmental aspects governing the use of shaker screens. Compliance with industry standards such as API (American Petroleum Institute) guidelines is crucial. Adhering to these standards ensures that the shaker screens not only perform optimally but also conform to safety and environmental protocols, avoiding potential legal issues. Trustworthiness in shaker screen mesh selection is further established through transparent communication with manufacturers and suppliers. Companies should look for partners who provide detailed product specifications, performance data, and who are capable of offering customized solutions. A reputable manufacturer can offer not only products but also insights and recommendations suited to specific operational needs. Transitioning into the marketplace, it's essential to stay informed about the latest trends and innovations in shaker screen technology. Participating in industry forums, attending trade shows, and engaging with industry publications are excellent ways to remain on the cutting edge. These venues provide opportunities to learn about new products, technologies, and methodologies that can significantly impact shaker screen performance. To foster trust and authority within the shaker screen mesh market, manufacturers should adopt a customer-centric approach, offering after-sales support and technical assistance. This builds a relationship based on reliability and service quality, enhancing brand reputation and customer loyalty. In conclusion, optimizing shaker screen mesh involves a blend of experience, technical expertise, authoritative adherence to industry standards, and robust trust-building practices. By prioritizing quality materials, innovative designs, and regulatory compliance, operations can achieve enhanced efficiency and longevity. Staying informed about and investing in technological advancements not only optimizes current processes but also prepares for future challenges in the ever-evolving industrial landscape.

Authoritativeness is strengthened by understanding the regulatory and environmental aspects governing the use of shaker screens. Compliance with industry standards such as API (American Petroleum Institute) guidelines is crucial. Adhering to these standards ensures that the shaker screens not only perform optimally but also conform to safety and environmental protocols, avoiding potential legal issues. Trustworthiness in shaker screen mesh selection is further established through transparent communication with manufacturers and suppliers. Companies should look for partners who provide detailed product specifications, performance data, and who are capable of offering customized solutions. A reputable manufacturer can offer not only products but also insights and recommendations suited to specific operational needs. Transitioning into the marketplace, it's essential to stay informed about the latest trends and innovations in shaker screen technology. Participating in industry forums, attending trade shows, and engaging with industry publications are excellent ways to remain on the cutting edge. These venues provide opportunities to learn about new products, technologies, and methodologies that can significantly impact shaker screen performance. To foster trust and authority within the shaker screen mesh market, manufacturers should adopt a customer-centric approach, offering after-sales support and technical assistance. This builds a relationship based on reliability and service quality, enhancing brand reputation and customer loyalty. In conclusion, optimizing shaker screen mesh involves a blend of experience, technical expertise, authoritative adherence to industry standards, and robust trust-building practices. By prioritizing quality materials, innovative designs, and regulatory compliance, operations can achieve enhanced efficiency and longevity. Staying informed about and investing in technological advancements not only optimizes current processes but also prepares for future challenges in the ever-evolving industrial landscape.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025