- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Helideck Safety Solutions for Enhanced Netting and Operational Efficiency

Understanding Helideck Netting Safety and Efficiency in Offshore Operations

In the modern era of offshore operations, safety is paramount. Helicopters play an essential role in the transportation of personnel and supplies to and from offshore installations, such as oil rigs and wind farms. Given the unique challenges posed by maritime environments, ensuring the safe landing and take-off of helicopters is critical. One vital aspect of this safety protocol is helideck netting.

What is Helideck Netting?

Helideck netting refers to safety nets that are installed around helidecks on offshore platforms. These nets serve multiple purposes they prevent personnel and equipment from falling overboard during helicopter operations, enhance the safety of landings and take-offs, and protect the helideck from adverse weather conditions. The nets are designed to absorb impacts and prevent accidents during helicopter maneuvers, which can be particularly challenging in windy or turbulent maritime conditions.

Importance of Helideck Netting

1. Accident Prevention The primary goal of helideck netting is to minimize the risk of accidents. Helicopter landings are complicated by factors such as high winds, waves, and movement of the platform itself. Helideck nets act as a barrier, capturing any equipment or personnel that may be at risk of falling during these critical operations.

2. Enhanced Safety Protocols In compliance with international safety regulations, helideck netting is an essential component of offshore safety protocols. Organizations such as the International Maritime Organization (IMO) and the International Organization for Standardization (ISO) emphasize the need for safety measures in aviation operations offshore. The use of netting demonstrates a commitment to employee safety and regulatory compliance.

3. Operational Efficiency Safety nets do not just enhance safety; they also contribute to operational efficiency. With reduced risks of accidents, helicopter operations can proceed with greater confidence. This, in turn, minimizes downtime and ensures that personnel and supplies are delivered promptly and safely.

helideck netting

4. Customizable Design Helideck netting can be tailored to fit the specific needs of different offshore installations. Factors such as the size of the helideck, the type of helicopter used, and the environmental conditions of the operational area can all influence the design and installation of netting. This customization ensures that each installation can operate effectively within its unique context.

Types of Helideck Netting

Helideck nets are typically made from high-strength materials designed to withstand harsh marine environments. Common materials include synthetic fibers, which provide durability and resistance to wear and tear. Depending on the specific needs, nets may vary in size, mesh density, and structural design to optimize their performance.

There are primarily two types of helideck netting

1. Static Nets These nets are fixed in place and designed to hold personnel and equipment in the event of a fall. They are typically anchored to the helideck structure and offer a rigid form of protection.

2. Dynamic Nets Unlike static nets, dynamic nets are designed to absorb impacts and allow for some movement. This can be particularly advantageous in high-wind conditions, where the force of the wind could lead to destabilization during helicopter operations.

Conclusion

Helideck netting represents a vital component of offshore safety measures, ensuring that helicopter operations are as safe and efficient as possible. With the increasing reliance on helicopters for offshore logistics, investing in quality helideck netting is a crucial step towards minimizing risks and ensuring the safety of personnel and equipment. As technology and design continue to evolve, the effectiveness of helideck netting will undoubtedly enhance, paving the way for safer and more efficient offshore operations. Understanding and implementing these safety measures is essential for the future of offshore aviation, where the stakes can be incredibly high. With the proper safety nets in place, the skies above our offshore installations can remain secure and reliable.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

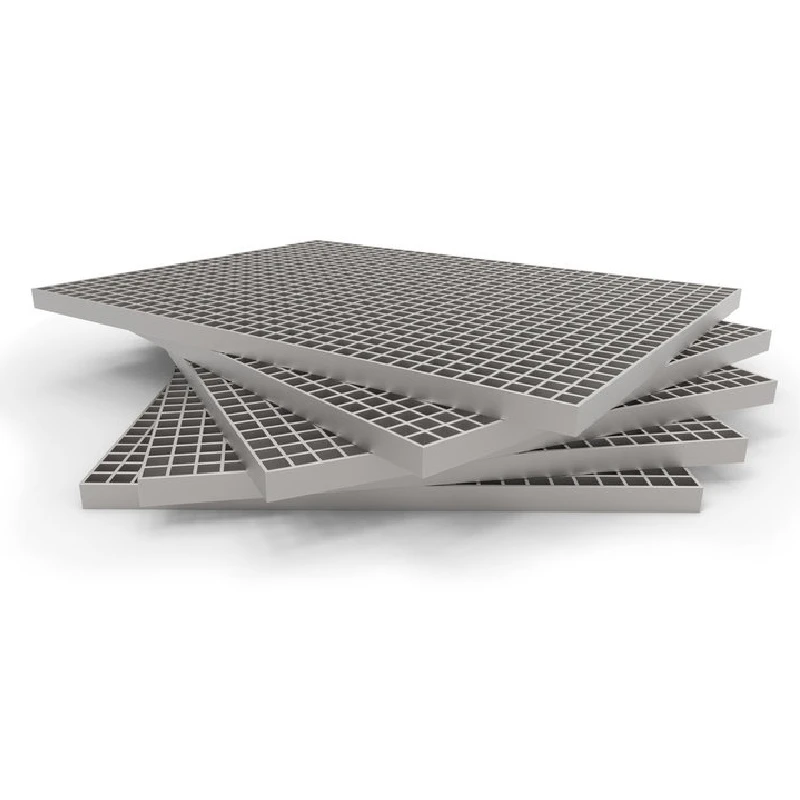

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025