- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

concrete weight coating mesh

Concrete weight coating mesh serves as an indispensable component in the construction and protection of subsea pipelines and infrastructure

. Its importance lies in its ability to offer stability, protection, and flexibility, ensuring that the pipelines remain undisturbed on the seabed. This article will delve into the intricate details of concrete weight coating mesh, emphasizing its role, benefits, and applications within the industry.

The use of concrete weight coating mesh is rooted in its capability to provide enhanced mechanical protection and added weight, stabilizing the pipelines against buoyancy and unpredictable ocean currents. This weight coating is specially designed to withstand the harsh marine environment, resisting degradation from saltwater exposure over extended periods. The robustness of the material ensures that the pipelines maintain their integrity, providing a seamless flow of resources without interruptions prevalent due to environmental factors.

One of the prominent advantages of using concrete weight coating mesh is its adaptability to different pipeline diameters and configurations. This flexibility ensures that regardless of the project specifics, the mesh can be customized to fit varying dimensions, optimizing handling and operational efficiency. The mesh not only adds physical weight but also acts as a protective shield, significantly reducing the risk of damage from external impacts.

Experts in marine construction highlight the application of concrete weight coating mesh in regions where pipelines traverse through rocky seabeds or areas prone to seismic activity. Here, the mesh absorbs shock and vibration, minimizing the potential adverse effects on the pipeline's structural integrity. Furthermore, as industries push into deeper waters, where pressures and temperatures vary drastically, the reliance on a trusted, sturdy protective layer becomes even more critical.

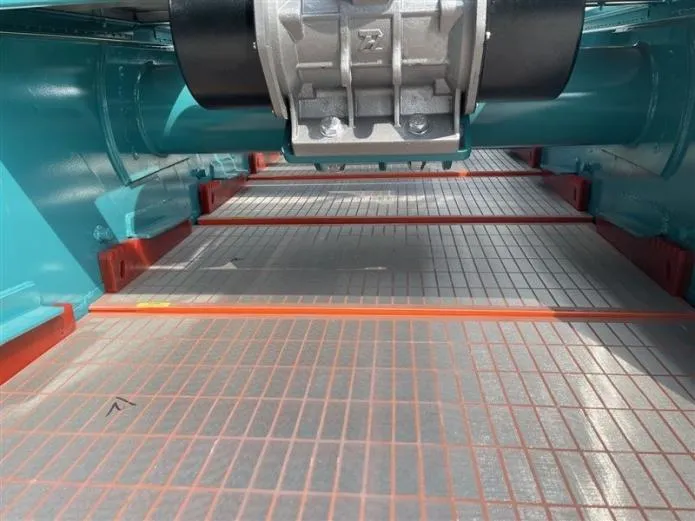

concrete weight coating mesh

The implementation of concrete weight coating mesh is also pivotal in reducing pipeline costs associated with maintenance and repair. By mitigating damage risk, pipelines require less frequent interventions, translating into cost savings and enhanced operational efficiency. The upfront investment in high-quality concrete weight coating can lead to long-term financial benefits, which is particularly appealing in large-scale offshore projects.

From an authority standpoint, industry leaders and engineers often laud these innovations in concrete weight coating mesh for setting higher safety and reliability standards. Companies involved in the production and application of this coating adhere to rigorous testing and quality control to meet international standards, ensuring that every inch is fit for purpose. This meticulous attention to fabrication detail solidifies the material's place as a reliable stalwart in subsea pipeline protection.

Ensuring trustworthiness, manufacturers provide certifications and documentation verifying that their concrete weight coating mesh has been subjected to and passed comprehensive assessments. Data supporting these evaluations offer tangible proof of performance, giving stakeholders confidence in their investment. Additionally, continuous research and development efforts strive to enhance product capabilities, further cementing the coating's reputation in the industry.

In conclusion, concrete weight coating mesh stands as a crucial player in the safeguarding and stability of offshore pipelines and related infrastructures. Its blend of physical strength, adaptability, and reliability underpins its essential status in marine environments. As the industry continuously evolves, investing in proven solutions like concrete weight coating mesh not only addresses current challenges but also paves the way for safer, more efficient operations moving forward.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025