- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

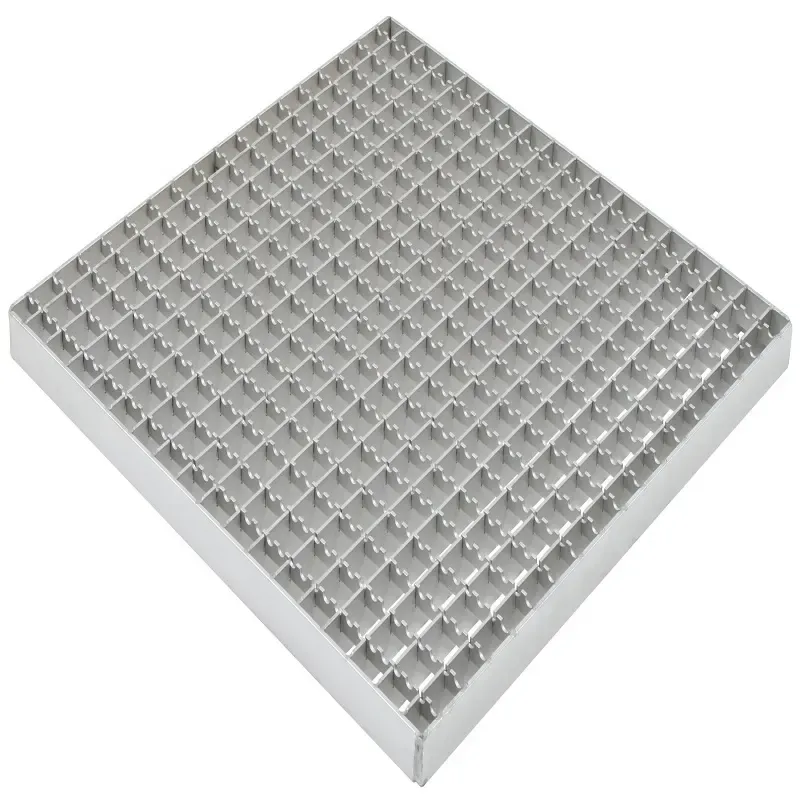

bar grating cost

Understanding the Cost of Bar Grating Factors and Considerations

Bar grating is an essential component in various industries, providing a sturdy and reliable surface solution for walkways, platforms, and other structures. These gratings come in different materials, sizes, and designs, affecting their overall cost. Understanding the factors that contribute to bar grating costs can help businesses and individuals make informed decisions, ensuring they select the right product for their specific needs.

Types of Bar Grating

Bar grating is primarily categorized based on material and type. The most common materials are

1. Steel Grating Often the most cost-effective option, steel grating offers excellent durability and strength. It is commonly used in industrial settings, but it may require protective coatings to prevent rust and corrosion, which can add to the long-term cost.

2. Aluminum Grating Lighter than steel, aluminum grating is resistant to corrosion, making it ideal for environments where moisture is a concern. While it generally has a higher upfront cost than steel, its longevity can make it a more economical choice in the long run.

3. Fiberglass (FRP) Grating This type of grating is known for its resistance to chemicals, corrosion, and UV rays. While typically more expensive than metal options, fiberglass grating provides unique benefits in specific applications, particularly in chemical processing facilities and marine environments.

4. Plastic Grating Finally, plastic grating offers a lightweight, corrosion-resistant option, typically used in residential or less demanding industrial applications. Cost can vary, but generally, it is one of the more affordable options.

Key Factors Influencing Cost

When considering bar grating, several factors can impact the overall cost

bar grating cost

1. Material Type As discussed, the material significantly affects price. Steel is usually the cheapest, while specialized materials like fiberglass can be much more expensive due to their unique properties.

2. Load Requirements The intended use of the grating impacts its design and cost. Heavy-duty applications require more robust grating solutions, which often cost more due to the materials and engineering involved.

3. Size and Thickness Larger and thicker grating panels will typically cost more due to the increased amount of material needed. Custom sizes can also add to the cost, as they often involve additional machining and handling.

4. Finish and Coatings Protective coatings and finishes designed to enhance durability, aesthetics, or slip resistance can significantly increase costs. For example, galvanized steel or powder-coated surfaces will generally be more expensive than untreated options.

5. Manufacturing Process The complexity of the grating design also plays a role. Standard configurations are usually more affordable compared to custom or intricate designs that may require specialized production techniques.

Cost Breakdown

To give a clearer picture, let's look at some ballpark costs associated with various types of bar grating

- Steel Grating Prices typically range from $5 to $30 per square foot, depending on thickness and coating options. - Aluminum Grating Generally costs between $30 and $45 per square foot. The price varies based on the grade of aluminum and the complexity of the design. - Fiberglass Grating These can range from $60 to $100 per square foot, reflecting their specialized manufacturing process and the material's unique properties. - Plastic Grating Pricing can fluctuate between $15 to $30 per square foot, making it a versatile option for cost-sensitive projects.

Conclusion

Investing in bar grating is essential for many applications, but understanding the cost implications is crucial for making the right choice. By considering material type, load requirements, size, finishes, and manufacturing processes, you can tailor your decision to your specific needs and budget constraints. Properly assessing these factors will enable businesses and individuals to select the most suitable bar grating solutions that meet their performance expectations without overspending. Whether for industrial, commercial, or residential use, having a clear grasp of bar grating costs will facilitate better purchasing decisions, ensuring durability and safety in every application.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025