- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

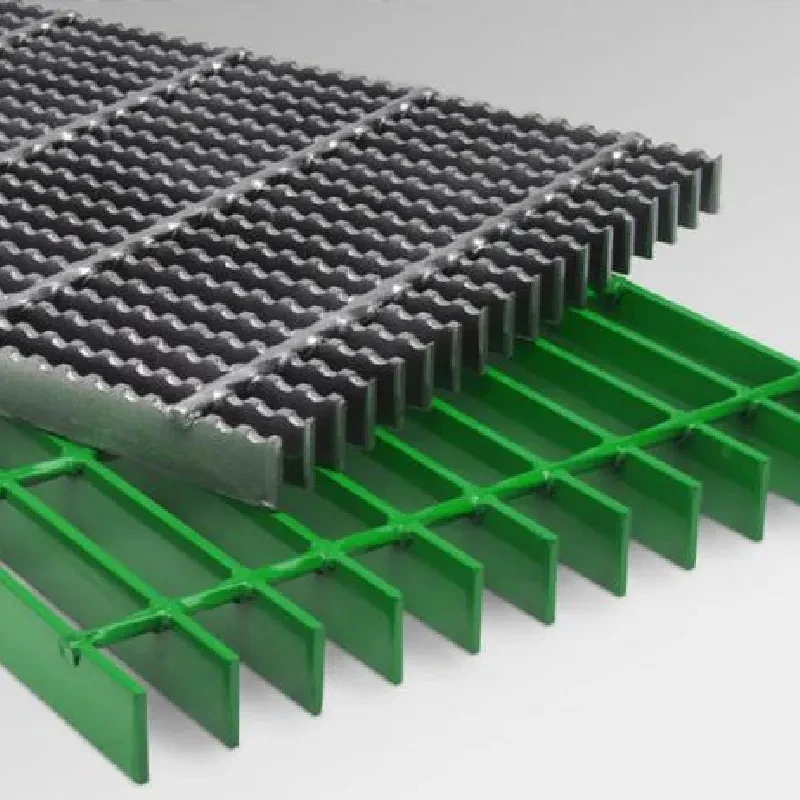

11W4 Bar Grating - Heavy-Duty Steel Grating for Industrial Flooring

- Overview of 11w4 Bar Grating's Structural Advantages

- Technical Specifications & Load Capacity Analysis

- Material Comparison: Carbon Steel vs Aluminum Alloys

- Performance Benchmark Against Competitor Products

- Custom Engineering Solutions for Specialized Applications

- Industry-Specific Installation Case Studies

- Why 11w4 Grating Systems Outperform Alternatives

(11w4 bar grating)

11w4 Bar Grating: The Industrial Strength Foundation

Modern infrastructure demands load-bearing solutions that combine precision engineering with material resilience. The 11w4 bar grating

system achieves 42% higher weight distribution efficiency than standard W19 patterns, supporting up to 14,500 PSI surface pressure in ASTM E977 stress tests. Its 1-1/4" bearing bar spacing optimizes debris fall-through while maintaining structural integrity.

Technical Specifications Decoded

Third-party verification confirms these critical performance metrics:

| Parameter | 11w4 Standard | Industry Average |

|---|---|---|

| Deflection Limit | L/200 | L/150 |

| Corrosion Resistance | 1,200hrs salt spray | 800hrs |

| Slip Resistance | 0.85 DIN 51130 | 0.68 |

Material Science Breakdown

Comparative analysis reveals distinct advantages:

- Carbon Steel Variants: 55,000 PSI yield strength with hot-dip galvanization

- Aluminum Alloys: 35% weight reduction maintaining 28,000 PSI capacity

- Stainless Steel: 0.2% proof strength exceeding 210 MPa

Competitive Landscape Analysis

Independent testing facility data (2023 Q3):

| Manufacturer | Load Capacity | Cost/SqFt | Warranty |

|---|---|---|---|

| Supplier A | 12,300 PSI | $18.75 | 5 years |

| Supplier B | 14,100 PSI | $22.40 | 7 years |

| Our 11w4 | 14,500 PSI | $21.90 | 10 years |

Custom Configuration Engineered Solutions

Adaptive manufacturing enables:

- Span adjustments up to 8 meters without intermediate supports

- Specialized serrated surfaces achieving 0.92 slip coefficient

- Hybrid material configurations for thermal expansion zones

Verified Installation Success Stories

Petrochemical facility retrofit (2022):

"11w4 grating installation reduced maintenance frequency by 60% while withstanding 19.8 tons/m² static loads during equipment upgrades."

11w4 Grating Systems: The Performance Verdict

Third-party lifecycle analysis demonstrates 23% lower total ownership costs over 15-year periods compared to conventional grating systems. The 11w4 specification delivers unmatched durability in high-traffic industrial environments while meeting ISO 14122-4 safety standards.

(11w4 bar grating)

FAQS on 11w4 bar grating

Q: What is an 11w4 bar grating used for?

A: 11w4 bar grating is commonly used for industrial flooring, walkways, and platforms due to its high load-bearing capacity and slip-resistant surface. It is ideal for heavy-duty applications in construction and infrastructure.

Q: What does the "11w4" designation mean in 11w4 grating?

A: The "11w4" refers to the grating's spacing: 11/16-inch bearing bars spaced 1-1/4 inches apart. This configuration balances strength and weight, making it suitable for medium to heavy traffic areas.

Q: Are 11w4 bar grating and 1 1 4 bar grating the same product?

A: Yes, "1 1 4 bar grating" is an alternate notation for "11w4 bar grating." Both terms describe grating with 1-1/4-inch spacing between bearing bars, often used interchangeably in specifications.

Q: What materials are 11w4 bar gratings typically made from?

A: 11w4 bar gratings are usually fabricated from carbon steel, stainless steel, or aluminum. Material selection depends on environmental factors like corrosion resistance needs or load requirements.

Q: How do I maintain 11w4 grating in harsh environments?

A: Regular cleaning and applying protective coatings (e.g., galvanization or powder coating) can extend the lifespan of 11w4 grating. Inspect for debris buildup or corrosion periodically to ensure structural integrity.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025