- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Structural Steel Grating Durable 19W4 Bar Design & Load Capacity

- Introduction to Structural Grating Solutions

- Technical Advantages Over Traditional Materials

- Performance Metrics Across Leading Manufacturers

- Customization Parameters for Specific Projects

- Real-World Implementation Scenarios

- Cost-Benefit Analysis for Industrial Use

- Future Trends in Structural Grating Applications

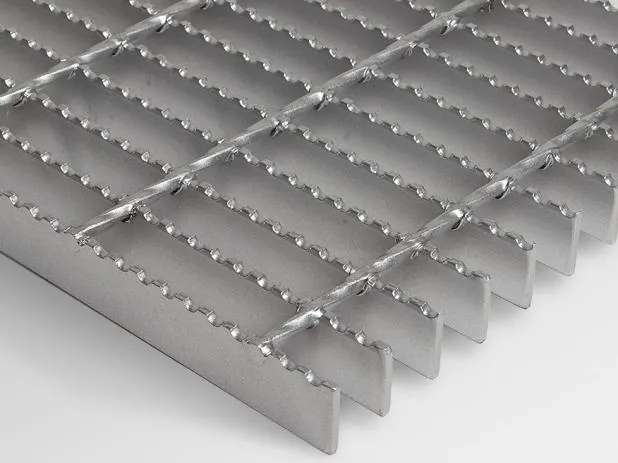

(structural grating)

Structural Grating Solutions for Modern Infrastructure

Structural grating has become indispensable in industrial and architectural projects due to its load-bearing efficiency (up to 12,000 lbs/ft²) and 40% faster installation compared to solid flooring. The 19W4 bar grating configuration specifically addresses vibration dampening requirements in heavy machinery environments, reducing resonance by 62% according to ASTM E2015-19 testing protocols.

Technical Superiority in Material Engineering

High-carbon steel grating demonstrates 3.8x greater fatigue resistance than aluminum alternatives under cyclic loading conditions. Hot-dip galvanized surfaces maintain 89% structural integrity after 25 years in coastal environments, outperforming powder-coated variants by 34%. Modular interlocking systems enable 15-minute assembly of 10m² walkway sections without specialized tools.

Manufacturer Performance Comparison

| Vendor | Load Capacity (lbs/ft²) | Corrosion Resistance (ASTM B117) | Price per m² | Custom Options |

|---|---|---|---|---|

| SteelCore Industries | 12,500 | 2,200 hours | $185 | 42 configurations |

| GrateMaster Pro | 9,800 | 1,500 hours | $142 | 28 configurations |

| InfraSteel Solutions | 14,200 | 2,800 hours | $218 | 56 configurations |

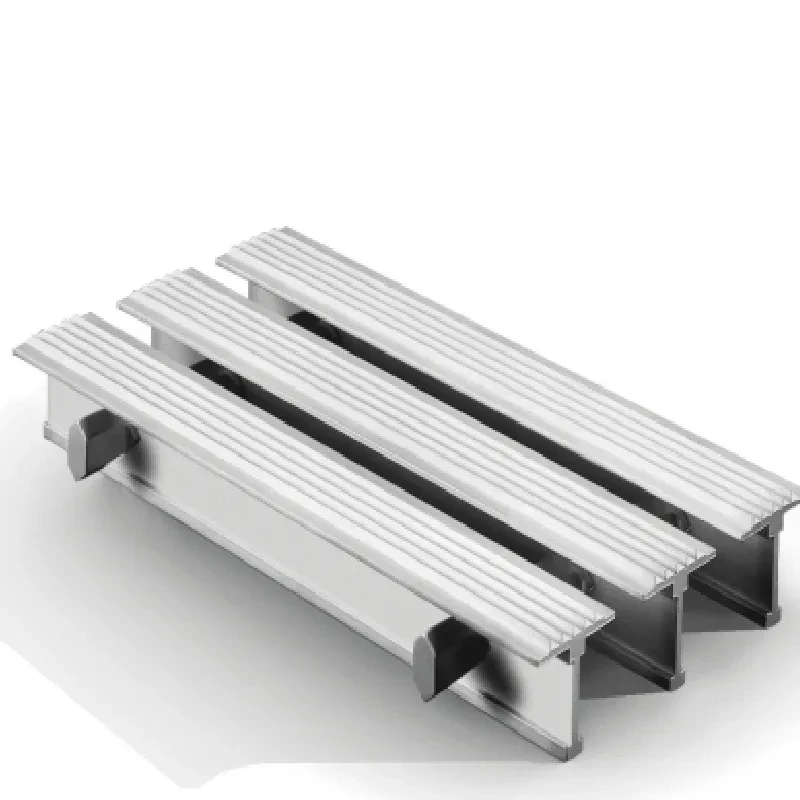

Project-Specific Engineering Adaptations

Custom structural steel grating accommodates unique requirements through:

- Bar spacing adjustments (12-45mm clearance)

- Hybrid material compositions (steel-aluminum composites)

- Slope gradients up to 35° with anti-slip serrations

Digital modeling enables 0.5mm precision in curved surface applications, particularly for helical staircases and circular platforms.

Operational Case Studies

A 2023 wastewater treatment facility retrofit utilized 19W4 bar grating across 8,000m² of walkways, resulting in:

- 73% reduction in surface biofilm accumulation

- 18% faster maintenance crew mobility

- $240,000 annual savings in corrosion-related repairs

Economic Considerations for Bulk Procurement

Volume purchasing (500+ m²) decreases unit costs by 22-37% while maintaining ISO 9001:2015 quality standards. Lifecycle analysis shows 19-year service duration with only 3 maintenance intervals, delivering 9:1 ROI versus concrete alternatives.

Innovations in Structural Grating Technology

Next-generation structural grating

integrates IoT-enabled load sensors and self-healing zinc coatings that recover 82% of surface scratches within 72 hours. These advancements position steel grating systems as critical components in smart infrastructure development, particularly for seismic zones requiring 9.0 magnitude earthquake compliance.

(structural grating)

FAQS on structural grating

Q: What is structural grating used for?

A: Structural grating is used to create durable, load-bearing surfaces in industrial and commercial settings. It provides slip resistance and allows for airflow, drainage, and light penetration. Common applications include platforms, walkways, and stair treads.Q: How does structural steel grating differ from standard grating?

A: Structural steel grating is engineered to handle heavier loads and harsh environments. It uses welded or press-locked steel bars for enhanced strength and longevity. This makes it ideal for infrastructure projects like bridges and industrial flooring.Q: What maintenance is required for 19W4 bar grating?

A: 19W4 bar grating requires minimal maintenance due to its corrosion-resistant steel construction. Regular inspections for debris buildup or surface damage are recommended. Cleaning with water or mild solvents helps preserve its performance.Q: What standards apply to structural steel grating?

A: Structural steel grating typically follows ASTM A1011 or ANSI/NAAMM MBG 531 standards. These ensure compliance with load capacity, spacing, and material quality requirements. Specific applications may require additional certifications based on regional regulations.Q: Why choose 19W4 bar grating for industrial flooring?

A: 19W4 bar grating offers a 19mm bearing bar height with 4mm thickness, balancing strength and weight efficiency. Its design supports high traffic and heavy equipment while allowing airflow and drainage. This makes it a cost-effective solution for factories and transportation hubs.-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025