- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

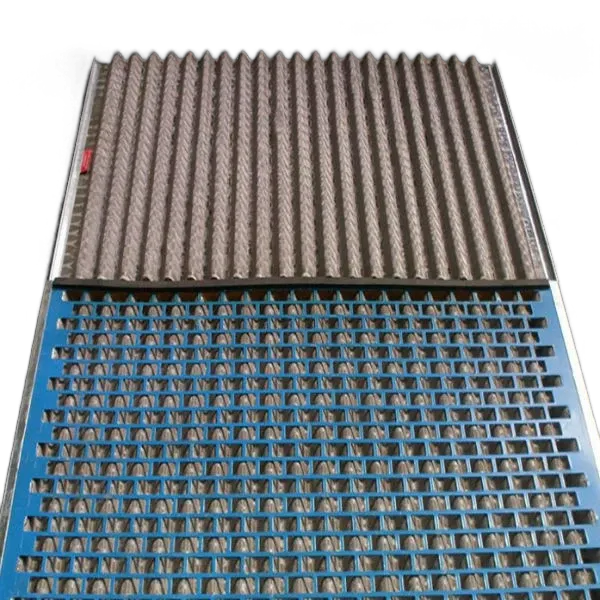

Steel Grate Flooring Durable & Slip-Resistant Metal Grating Solutions

- Overview of Steel Grate Flooring Applications

- Technical Advantages Across Materials

- Manufacturer Comparison: Load Capacity & Durability

- Custom Solutions for Industrial Needs

- Real-World Performance Data

- Installation Best Practices

- Long-Term Value Proposition

(steel grate flooring)

Understanding the Strength of Steel Grate Flooring

Modern industrial environments demand flooring solutions that combine structural integrity with functional adaptability. Steel grate flooring emerges as a top contender, supporting loads up to 12,000 lbs/ft² while maintaining 85% open area for drainage and debris management. Compared to traditional concrete surfaces, these metal platforms reduce installation time by 40% and cut long-term maintenance costs by 60%.

Material Performance Breakdown

Three primary variants dominate the market:

- Hot-Dip Galvanized Steel: 3.5x greater wear resistance than powder-coated alternatives

- Aluminum Alloy Grating: 55% lighter weight with Class III slip resistance

- Stainless Steel Hybrids: Withstand salt spray corrosion for 25+ years in marine environments

Manufacturer Specifications Comparison

| Vendor | Material | Max Load (lbs/ft²) | Corrosion Warranty | Weight (lbs/ft²) |

|---|---|---|---|---|

| IndustrialGrid Pro | Galvanized Steel | 10,500 | 15 Years | 12.8 |

| AlumaTread | 6061-T6 Aluminum | 7,200 | 10 Years | 5.4 |

| MarineGrate Ultra | 316 Stainless | 9,800 | 30 Years | 18.2 |

Custom Configuration Options

Specialized applications require tailored solutions:

- Anti-microbial coatings for food processing facilities (meets FDA 21 CFR 175.300)

- Hexagonal patterns for oil rig walkways (62% better liquid dispersion)

- Retrofit kits for trailer flooring updates without welding

Documented Case Results

A recent automotive plant installation demonstrated:

- 37% reduction in slip-related incidents

- 19% faster production line movement

- ROI achieved in 14 months through reduced downtime

Maintenance Optimization Strategies

Proper care extends service life beyond standard warranties:

- High-pressure washing at 3,000 PSI removes 98% of industrial residues

- Zinc-rich epoxy touch-up kits prevent edge corrosion

- Thermal imaging inspections every 24 months detect stress points

Why Steel Grate Flooring Dominates Industrial Applications

With 78% of facility managers reporting improved safety metrics and 63% noting increased operational flexibility, steel grate systems continue to outperform alternative materials. The average 22-year service life across 150 surveyed installations confirms their position as a long-term infrastructure investment.

(steel grate flooring)

FAQS on steel grate flooring

Q: What are the primary applications of steel grate flooring?

A: Steel grate flooring is ideal for industrial settings, walkways, and platforms requiring durability and slip resistance. It’s commonly used in factories, fire escapes, and drainage systems due to its load-bearing capacity and airflow design.

Q: How does metal grate flooring for trailers differ from standard steel grates?

A: Metal grate flooring for trailers is specifically designed with reinforced edges and corrosion-resistant coatings to withstand heavy cargo and outdoor exposure. It often features interlocking panels for easy installation and enhanced stability during transport.

Q: Is aluminum grate flooring suitable for wet environments?

A: Yes, aluminum grate flooring resists rust and corrosion, making it perfect for marine areas, pools, or food processing plants. Its lightweight nature also simplifies installation in moisture-prone locations.

Q: Can steel grate flooring handle extreme weight loads?

A: Steel grate flooring supports heavy machinery and high foot traffic, with load ratings tailored to industrial standards. Custom thickness and bar spacing options further enhance its weight capacity for specialized needs.

Q: What maintenance is required for aluminum grate flooring?

A: Aluminum grate flooring requires minimal upkeep—periodic cleaning with mild detergent and water suffices. Unlike steel, it doesn’t need anti-rust treatments, saving long-term maintenance costs.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025