- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Shale Shaker Screen - Anping County Hangshun Wire Mesh Manufacture Co., Ltd | Solid Control Solutions&Precision Engineering

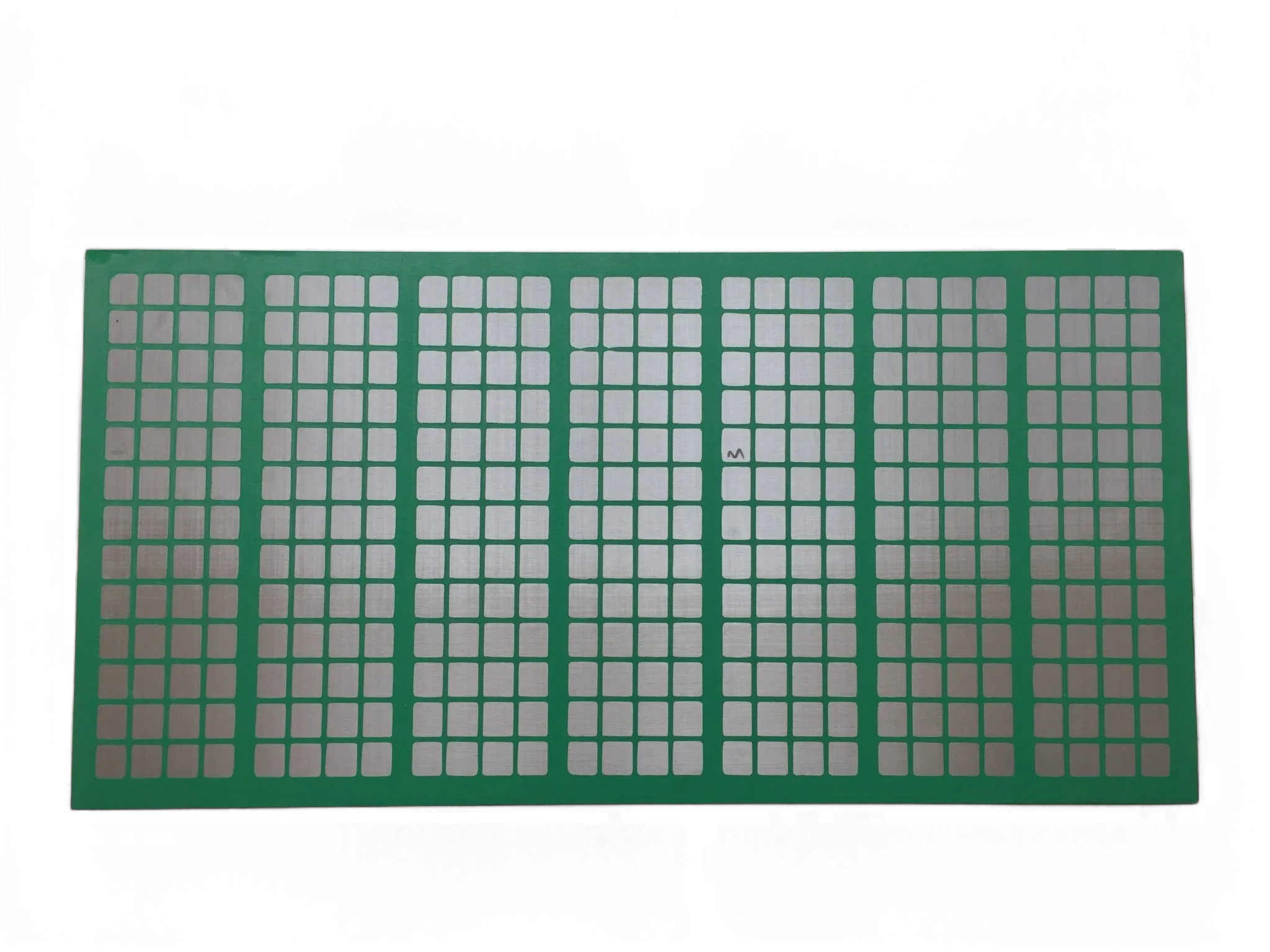

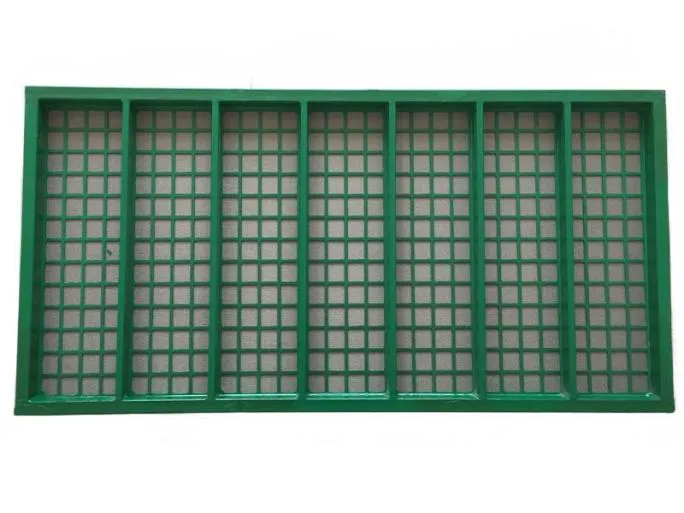

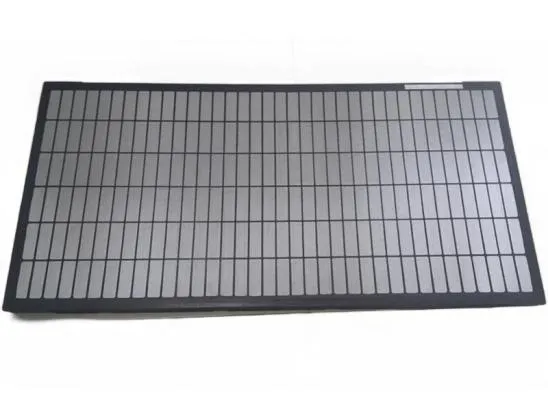

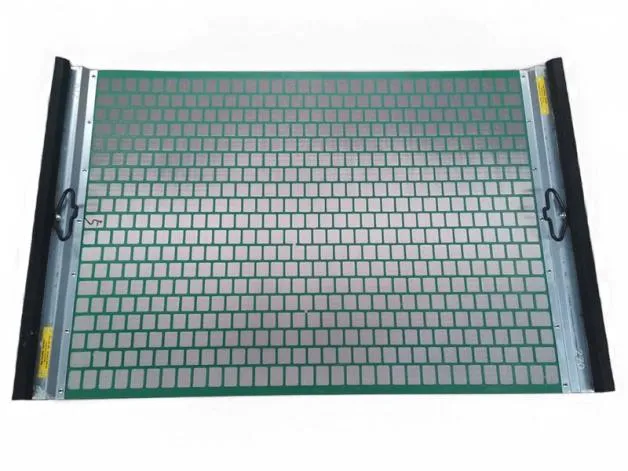

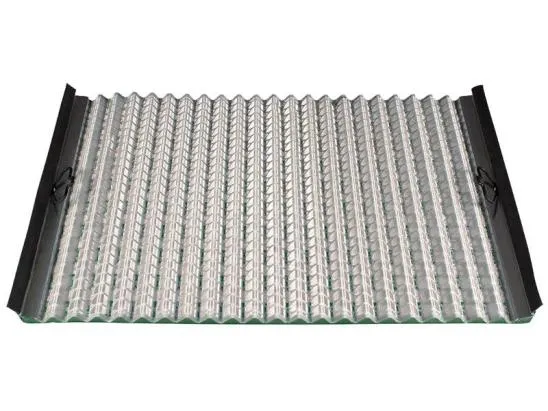

The shale shaker screen is a critical component in modern drilling operations, designed to separate solid cuttings from drilling fluids efficiently. As a vital part of the solid control system, these screens ensure optimal performance in oil and gas extraction, horizontal directional drilling, and environmental protection applications. This article explores the advanced features, technical specifications, and practical applications of shale shaker screen mesh, manufactured by Anping County Hangshun Wire Mesh Manufacture Co., Ltd, a leading provider of industrial filtration solutions.

Product Functionality and Core Advantages

Shale shaker screens are engineered to filter drilling cuttings from mud (drilling fluid) through a multi-layered stainless steel wire mesh system. This dual or triple-layered structure ensures shale shaker screen mesh provides exceptional filtration accuracy, capturing fine solid particles while allowing excess mud to drain back into the system. The screens are designed to withstand high mechanical stress and corrosive environments, making them ideal for demanding drilling conditions.

Key Features

- High Strength and Load Capacity: Constructed with durable stainless steel or carbon steel, these screens can bear heavy drilling fluid loads without deformation.

- Excellent Processing Efficiency: The wave-shaped design maximizes throughput, reducing downtime and improving operational efficiency.

- Corrosion and Wear Resistance: Surface coatings enhance longevity, even in harsh chemical environments.

- Adaptability: Available in steel frame, composite frame, and hook strip configurations, these screens fit various shale shaker models.

- Superior Quality Control: Free from defects like bumps, warping, or solder spatter, ensuring reliable performance.

- Easy Maintenance: Simple installation and replacement procedures minimize operational disruptions.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | Stainless steel, carbon steel |

| Surface Treatment | Coating (black, green, blue, or custom colors) |

| Production Process | Weaving and perforating |

| Types | Steel frame, composite frame, hook strip, wave screen |

| Standards Compliance | ISO 13501, API RP 13C, GBT 11648, GBT 11650 |

Applications in Diverse Industries

Shale shaker screens are widely used in the following fields:

- Oil and Gas Drilling: Essential for solid control in rotary drilling and directional drilling operations.

- Coal Bed Methane Drilling: Ensures efficient removal of fine cuttings in low-permeability reservoirs.

- Shale Gas Extraction: Critical for maintaining fluid purity in hydraulic fracturing processes.

- Environmental Protection: Used in river sludge treatment and soil remediation projects.

- Non-Excavation Horizontal Directional Drilling: Reduces contamination risks during underground pipeline installation.

Company Background and Expertise

Manufactured by Anping County Hangshun Wire Mesh Manufacture Co., Ltd, a leading Chinese manufacturer specializing in industrial filtration solutions, these shale shaker screen combine advanced engineering with rigorous quality control. With over a decade of experience, the company adheres to international standards such as ISO and API, ensuring products meet the demands of global drilling operations.

Why Choose Our Shale Shaker Screens?

Our shale shaker screen mesh offers unmatched performance due to its innovative design and high-quality materials. For instance, the wave shale shaker screen provides the highest processing efficiency, while the steel frame shale shaker screen is ideal for heavy-duty applications. Whether you need a shale shaker screen price that balances cost and performance or a shale shaker screen factory solution, our product line delivers reliable results.

Industry Standards and Certifications

Compliance with global standards is a cornerstone of our manufacturing process. Our shale shaker screen meets the requirements of NIST (National Institute of Standards and Technology) and other regulatory bodies, ensuring consistency in performance and safety. For example, the NIST standards for material testing and quality control are integral to our production protocols.

Conclusion

Investing in high-quality shale shaker screens is essential for optimizing drilling operations and reducing maintenance costs. With their advanced design, durability, and adaptability, these screens are a vital asset for any drilling project. For more information on shale shaker screen price, product specifications, or shale shaker screen factory solutions, visit Anping County Hangshun Wire Mesh Manufacture Co., Ltd.

References

NIST (National Institute of Standards and Technology) standards ensure the reliability and performance of industrial filtration systems. For further details on material testing protocols and quality assurance, refer to NIST's official publications.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025