- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

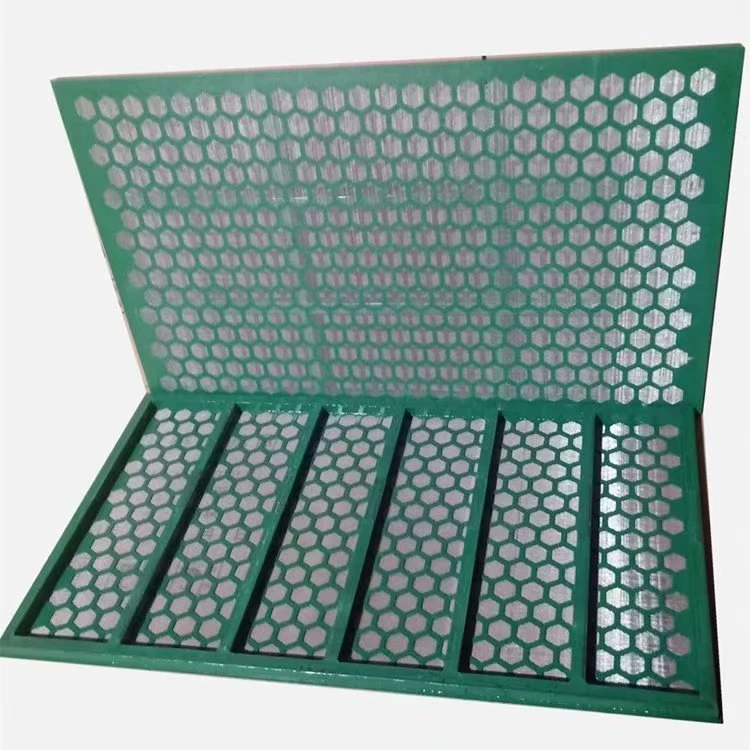

Exploring the Benefits and Features of SWACO Shaker Screens for Efficient Filtration

Understanding SWACO Shaker Screens A Key Component in the Drilling Industry

In the oil and gas industry, efficient drilling operations are crucial for productivity and environmental responsibility. One essential component in achieving these goals is the shaker screen, particularly those produced by SWACO, a division of Schlumberger. These screens play a vital role in the drilling fluid recycling process, enhancing the efficiency of mud systems and ensuring optimum drilling performance.

What are Shaker Screens?

Shaker screens are integral parts of shale shakers, which are equipment used to separate solid particles from drilling fluids. During the drilling process, a mixture of water, clay, and various chemicals—commonly referred to as 'mud'—is used to facilitate the extraction of oil or gas. As the drill bit penetrates the earth, it produces cuttings and debris, which must be removed to maintain the efficiency of the drilling operation. Shaker screens effectively filter out these solid materials, allowing cleaned drilling fluid to be recirculated.

The Role of SWACO in the Market

SWACO has established itself as a leader in the manufacture and supply of high-quality shaker screens. Their products are designed to meet the demanding requirements of today’s drilling operations, offering various mesh sizes and configurations tailored for specific drilling conditions. SWACO screens are renowned for their durability, efficiency, and ability to reduce the overall costs associated with drilling operations.

One notable feature of SWACO shaker screens is their innovative composite frame design, which significantly improves the strength-to-weight ratio. This design not only enhances the lifespan of the screens but also optimizes the fluid flow, contributing to better separation and less downtime. Moreover, SWACO screens apply advanced technology to ensure uniformity in mesh sizes, allowing for precise control over the sizing of drilled cuttings.

Advantages of SWACO Shaker Screens

swaco shaker screens

1. Improved Performance High-quality materials and advanced engineering contribute to the superior performance of SWACO shaker screens, resulting in effective separation and better fluid management.

2. Cost Efficiency By extending the lifespan of the screens and reducing the need for frequent replacements, SWACO products can lower operational costs over time.

3. Environmental Benefits Efficient separation of solids from drilling fluids minimizes waste generation and promotes better recycling of drilling materials, leading to reduced environmental impact.

4. Adaptability SWACO offers a range of screen options suitable for various drilling conditions, including shale, mud, and other formations, providing flexibility for operators facing diverse challenges.

The Future of Shaker Screens

As drilling technologies evolve, the demand for innovative and efficient shaker screens continues to grow. The oil and gas industry is increasingly focusing on sustainability and reducing environmental footprints. Companies like SWACO are at the forefront of this transformation, continuously investing in research and development to enhance their products and meet the changing needs of the market.

In conclusion, SWACO shaker screens are critical components in achieving efficient and sustainable drilling operations. With their advanced design, durability, and focus on performance, they stand out as a reliable choice for drilling companies worldwide. As the industry continues to embrace new technologies and practices, SWACO's commitment to quality and innovation will undoubtedly play a significant role in shaping the future of drilling operations.

-

Welded Steel Grating: The Strong Foundation for Industrial SafetyNewsJul.16,2025

-

Strong and Safe: Swaged Grating SolutionsNewsJul.16,2025

-

Smart Choice For Industrial Safety MeshNewsJul.16,2025

-

Press-Locked Steel Grating: The Ultimate in Strength and SafetyNewsJul.16,2025

-

Keep Worksites Safer With Practical NettingNewsJul.16,2025

-

Helideck Safety Nets: Your First Line of DefenseNewsJul.16,2025