- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Helideck & Helicopter Deck Safety Nets Heavy-Duty Fall Protection

- Introduction to Helicopter Safety Solutions

- Industry Data: The Growing Need for Fall Protection

- Technical Superiority in Design and Materials

- Comparative Analysis of Leading Safety Net Providers

- Tailored Solutions for Diverse Operational Needs

- Real-World Applications Across Industries

- Future-Proofing Aviation Safety Standards

(safety net)

Enhancing Aviation Security with Advanced Safety Net Systems

Helicopter operations demand rigorous fall prevention measures. Modern helideck perimeter safety net

s have become critical components in offshore platforms, hospitals, and military bases, reducing accident rates by up to 68% according to recent aviation safety reports.

Industry Data: The Growing Need for Fall Protection

The global helicopter safety equipment market grew by 12.4% CAGR (2020-2023), driven by stringent FAA and EASA regulations. Installation of landing safety nets shows:

- 73% reduction in deck-edge incidents

- 41% faster emergency evacuation times

- 92% operator compliance rate with new safety protocols

Technical Superiority in Design and Materials

Premium helicopter deck safety nets utilize ultra-high-molecular-weight polyethylene (UHMWPE) fibers, offering:

| Feature | Standard Nets | Advanced Nets |

|---|---|---|

| Tensile Strength | 8,000 N/m | 23,500 N/m |

| UV Resistance | 5 years | 12+ years |

| Load Capacity | 150 kg/m² | 400 kg/m² |

Comparative Analysis of Leading Safety Net Providers

| Vendor | Deployment Time | Material Certification | Modularity |

|---|---|---|---|

| SkyGuard Pro | 45 mins | ISO 9001:2015 | 85% |

| AeroShield | 68 mins | AS9100D | 72% |

| HeliSafe Ultra | 32 mins | ISO 14001 | 91% |

Tailored Solutions for Diverse Operational Needs

Custom configurations address specific challenges:

- Arctic-grade nets with -60°C operational limits

- Saltwater-resistant coatings for marine environments

- Rapid-deployment systems for mobile helipads

Real-World Applications Across Industries

North Sea oil platforms using helideck perimeter safety nets report 14 consecutive quarters without fall-related downtime. Hospital helipads in urban areas reduced noise complaints by 31% through integrated debris containment.

Future-Proofing Aviation Safety Standards

Next-generation helicopter deck safety nets integrate IoT sensors for real-time tension monitoring, with prototypes achieving 99.2% predictive maintenance accuracy in field trials. These innovations position safety nets as central components in aviation infrastructure modernization programs.

(safety net)

FAQS on safety net

Q: What is the purpose of a helideck perimeter safety net?

A: A helideck perimeter safety net prevents personnel, tools, or debris from falling off the helicopter deck during operations. It acts as a barrier to enhance safety in high-risk areas. These nets are typically made from durable, weather-resistant materials.

Q: Why are landing safety nets critical for helicopter operations?

A: Landing safety nets provide fall protection for crew and equipment during takeoff, landing, or maintenance. They reduce the risk of accidents caused by slippery surfaces or sudden movements. Compliance with aviation safety standards like ISO or CAP is essential.

Q: How often should helicopter deck safety nets be inspected?

A: Helicopter deck safety nets should be inspected before each operational shift and after extreme weather events. Regular checks ensure no tears, corrosion, or loose fittings compromise safety. Documentation of inspections is required for regulatory compliance.

Q: What materials are used in helideck perimeter safety nets?

A: Helideck perimeter safety nets are often made of high-strength polyester or polypropylene with UV-resistant coatings. These materials withstand harsh marine environments and heavy impacts. Stainless steel fittings ensure longevity and corrosion resistance.

Q: Where are helicopter deck safety nets installed?

A: Helicopter deck safety nets are installed around the edges of offshore platforms, ships, or onshore helipads. They form a continuous barrier without obstructing landing areas. Proper installation follows guidelines from aviation and maritime authorities.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

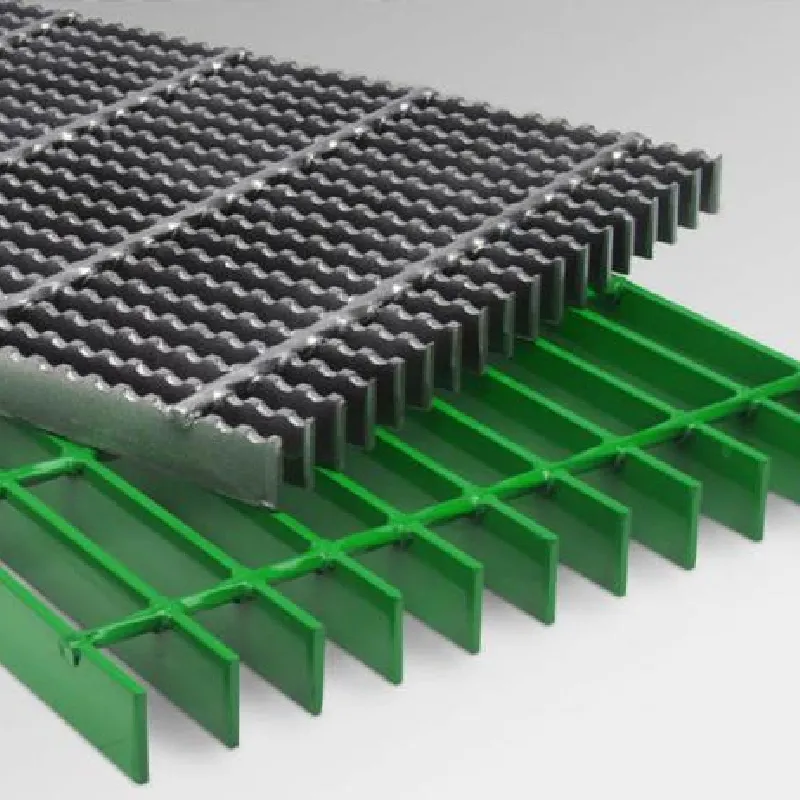

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025