- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

metal grating price

Understanding the Price Dynamics of Metal Grating

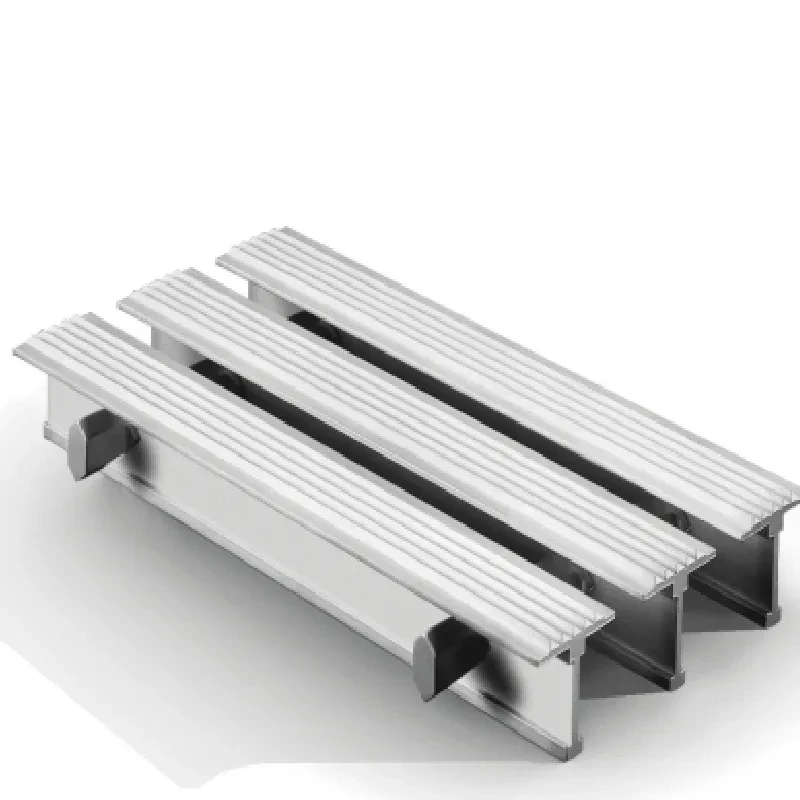

Metal grating has become an integral component in various industries, serving purposes that range from safety and accessibility to drainage and support structures. With its versatility and durability, the demand for metal grating continues to grow. However, one factor that potential buyers often grapple with is pricing. This article aims to break down the components that influence metal grating prices and help consumers make informed decisions.

Types of Metal Grating and Their Impact on Price

Metal grating comes in several types, each with unique characteristics and applications. The most common materials used are steel, aluminum, and stainless steel. Carbon steel grating is typically the most affordable option, yet it may not withstand harsh environments, making it less suitable for applications requiring corrosion resistance. On the other hand, stainless steel grating offers superior durability and corrosion resistance, but it comes at a premium price due to the high cost of raw materials.

Aluminum grating strikes a balance between weight, strength, and cost. While it may be more expensive than carbon steel, its lightweight nature makes it easier to transport and install, potentially saving on labor costs. The choice of material plays a pivotal role in the final price of metal grating.

Factors Influencing the Pricing of Metal Grating

Beyond the type of material, several other factors influence the price of metal grating. These include

metal grating price

1. Manufacturing Process The manufacturing technique adopted also affects cost. For instance, grating produced through a more intricate welding process may be priced higher due to the labor and time required. Standard pressed or welded gratings are more common and may be available at a lower price point.

2. Dimensions and Customization The dimensions of the grating affect pricing as well. Custom sizes and shapes will generally incur additional costs compared to standard sizes. For projects requiring specific measurements, the price may increase to accommodate the specialized manufacturing processes.

3. Surface Finish The type of surface finish can significantly alter the cost of metal grating. Options such as galvanized coatings for rust protection or powder coating for aesthetic appeal tend to increase the overall price. Buyers should consider the long-term benefits of these finishes against their initial costs.

4. Volume and Bulk Orders Many suppliers offer discounts for bulk orders. If an organization requires a large quantity of metal grating, negotiating for a better price can yield substantial savings. It’s often worthwhile to contact manufacturers directly to discuss pricing options for larger projects.

5. Market Trends Like many commodities, metal prices are subject to market fluctuations. Factors such as supply chain disruptions, trade tariffs, and changes in demand can lead to price variations. Staying informed about market trends can assist buyers in making timely purchases.

Conclusion

In conclusion, the pricing of metal grating is influenced by a myriad of factors ranging from the material used to manufacturing processes, sizes, finishes, and market conditions. Understanding these variables can help buyers evaluate their options more effectively and make choices that align with their budget and project requirements. Whether you are in construction, manufacturing, or another industry, investing time to assess the costs and benefits of different metal grating solutions can lead to better purchasing decisions and substantial long-term savings. As the demand for quality metal grating continues to grow, keeping abreast of pricing trends will be crucial in navigating this important aspect of your project planning.

-

Unlocking Efficiency with Premium Shaker ScreensNewsAug.05,2025

-

Safety and Style with Metal Grate WalkwayNewsAug.05,2025

-

Optimize Operations with Shaker Screen SolutionsNewsAug.05,2025

-

Enhance Your Space with Steel GratingNewsAug.05,2025

-

Durability with Concrete Weight Coating MeshNewsAug.05,2025

-

Discover the Power of Perimeter Safety NetNewsAug.05,2025