- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

concrete weight coating pipe mesh

Understanding Concrete Weight Coating for Piping and its Mesh Applications

Concrete weight coating (CWC) is a technique utilized predominantly in the pipeline industry to provide additional weight and protection to pipelines. This is especially crucial for underwater pipelines or those installed in areas where soil movement is a concern. CWC involves applying a layer of concrete around the pipe, which enhances its stability and helps prevent buoyancy in marine environments. This not only protects the pipe from external forces but ensures its longevity and structural integrity throughout its operational lifespan.

The Process of Concrete Weight Coating

The application of concrete weight coating is a meticulous process. Initially, the pipes are cleaned to remove rust, debris, and contaminants that could affect the bond between the concrete and the pipe surface. The next step involves the preparation of a concrete mixture, which typically consists of cement, sand, and aggregates. The concrete must be of high quality to withstand the harsh conditions it may encounter during its service.

Once the pipe is ready, it is conveyed through a coating facility where it undergoes the actual coating process. There are various techniques for applying the concrete, with the most common methods being centrifugal casting and static coating. In centrifugal casting, the pipes are rotated at high speeds while concrete is introduced, allowing for an even distribution. On the other hand, static coating involves manually or mechanically applying the concrete mixture onto the pipe. After the concrete is applied, it is cured to enhance its strength.

Benefits of Concrete Weight Coating

The advantages of using concrete weight coating are manifold. Firstly, the added weight of the concrete helps ensure that the pipes remain submerged on the seabed, preventing them from floating during installation or due to changes in external conditions. This is particularly important for offshore oil and gas pipelines, where maintaining position is vital for operational efficiency.

Moreover, the concrete acts as a protective barrier against physical damage. During transportation and installation, pipelines face several risks, including impacts from machinery, falling debris, and environmental conditions. The concrete layer absorbs these shocks, reducing the likelihood of damage to the pipeline itself.

concrete weight coating pipe mesh

Additionally, concrete weight coating provides excellent durability against corrosion and environmental degradation. While pipelines may be subject to various types of corrosion — from natural elements like water and salt to chemical exposure — the concrete surface reduces direct exposure to such damaging agents, thus prolonging the lifespan of the pipe.

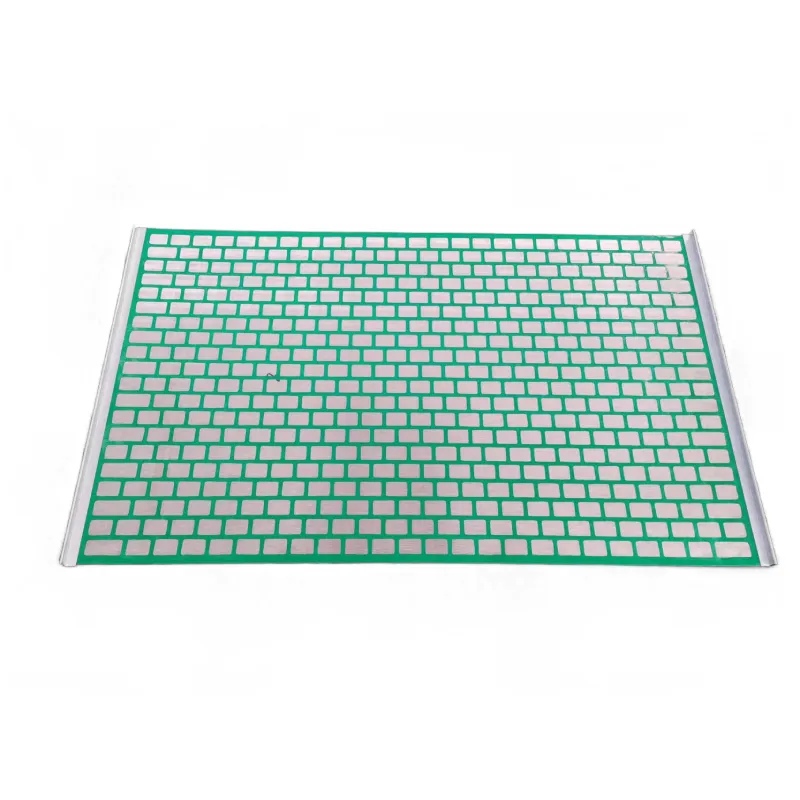

The Role of Mesh in Concrete Weight Coating

A crucial aspect of the concrete weight coating process is the integration of mesh, typically made from steel, within the coating. This mesh serves multiple purposes. Primarily, it enhances the tensile strength of the concrete, ensuring that it can withstand not only external pressures but also tensile forces that may occur during installation and over the lifecycle of the pipeline.

The incorporation of mesh also helps with the adhesion between the concrete and the pipe, creating a composite material that combines the beneficial properties of both components. Furthermore, the mesh can assist in preventing cracking during curing and throughout the pipe's service.

Conclusion

In summary, concrete weight coating for pipes is an essential technology in the modern pipeline industry, particularly for underwater installations. The process of applying concrete not only increases the weight and stability of pipelines but also provides vital protection against damage and corrosion. The use of reinforcing mesh within the concrete layer further enhances the overall performance and reliability of the coating.

As pipeline infrastructure continues to expand globally, adopting advanced coating techniques and materials becomes crucial in ensuring the safety and efficiency of energy transportation. Understanding the importance of concrete weight coating, alongside its applications and benefits, underscores its significance in the realm of pipeline engineering, enabling us to meet the ever-growing demands of the energy sector.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025