- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

फरवरी . 14, 2025 12:36

Back to list

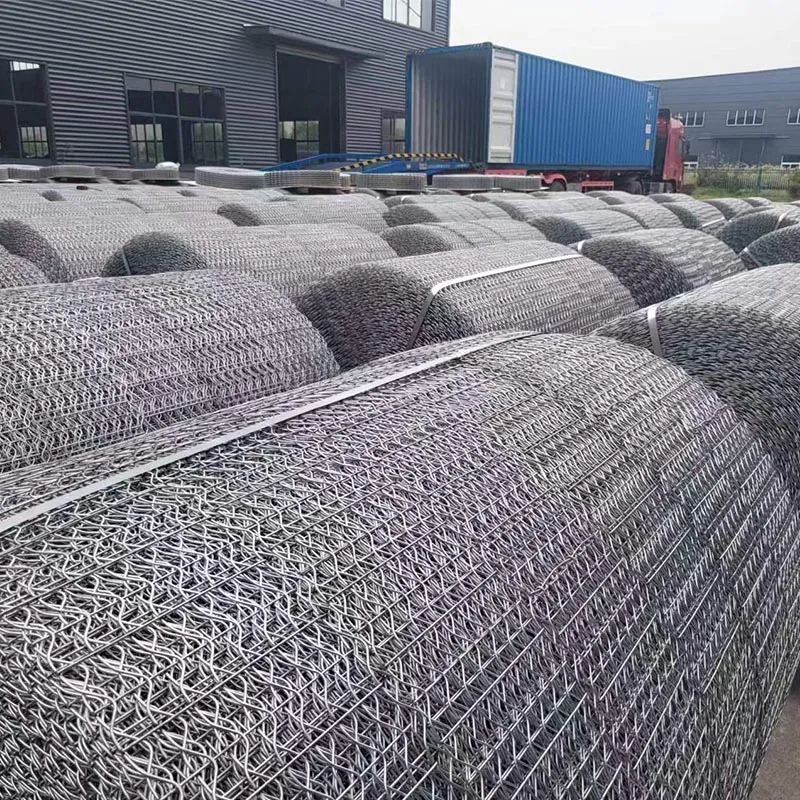

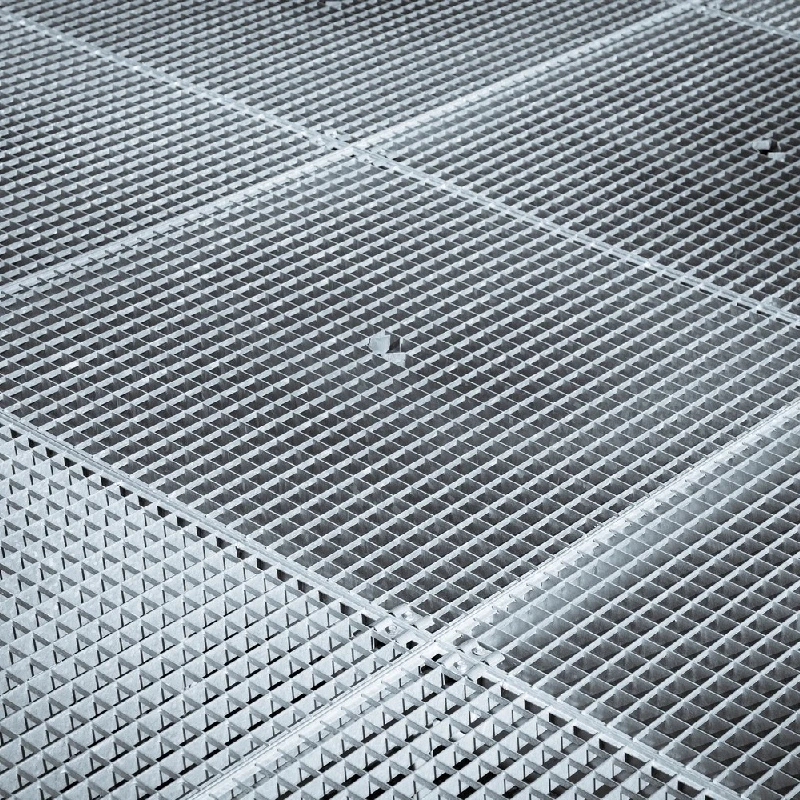

bar grating cost

Navigating the intricacies of bar grating pricing requires an understanding rooted in experience and expertise, coupled with a nod toward the trustworthiness and authority of the information provided. As an essential component in various industrial and architectural applications, the cost of bar grating is influenced by myriad factors, making the journey toward purchasing a wise investment of both time and resources.

Supply chain dynamics and market fluctuations also play a pivotal role in determining price. As with many materials, the cost of raw materials such as steel and aluminum can fluctuate based on global economic conditions, affecting overall pricing. Moreover, logistical considerations—including manufacturing location, shipping distance, and delivery speed—add another layer of complexity, emphasizing the necessity of understanding how and why prices vary from one supplier to another. Navigating supplier credibility is critical in the purchasing decision-making process. Choosing a supplier with a robust track record, positive reviews, and a transparent pricing model can heighten the sense of reliability and security in the purchase. Engaging with suppliers that offer comprehensive support, including consultation and customization services, can enhance the overall investment value, outweighing initial cost considerations. Ensuring value in bar grating procurement, beyond initial costs, involves considering aspects such as long-term durability, maintenance requirements, and the total life cycle of the product. Investing in high-quality grating, though more costly at the outset, often results in savings by minimizing replacements and repairs over time, not to mention reducing potential hazards associated with product failure. As the demand and technology surrounding bar grating continue to evolve, staying informed about innovations in material science and manufacturing techniques can provide purchasers with a strategic advantage. Emerging technologies such as enhanced corrosion-resistant coatings or eco-friendly production processes not only offer functional benefits but can also align with broader organizational sustainability goals, indirectly influencing cost strategies. In conclusion, understanding bar grating costs requires a seamless blend of experience, expertise, and authoritative insight, grounded in trustworthiness concerning both product and supplier. By considering material type, manufacturing method, customization, and supplier credibility, purchasers can not only navigate the complexities of cost efficiently but also make informed decisions that yield long-term benefits both economically and functionally.

Supply chain dynamics and market fluctuations also play a pivotal role in determining price. As with many materials, the cost of raw materials such as steel and aluminum can fluctuate based on global economic conditions, affecting overall pricing. Moreover, logistical considerations—including manufacturing location, shipping distance, and delivery speed—add another layer of complexity, emphasizing the necessity of understanding how and why prices vary from one supplier to another. Navigating supplier credibility is critical in the purchasing decision-making process. Choosing a supplier with a robust track record, positive reviews, and a transparent pricing model can heighten the sense of reliability and security in the purchase. Engaging with suppliers that offer comprehensive support, including consultation and customization services, can enhance the overall investment value, outweighing initial cost considerations. Ensuring value in bar grating procurement, beyond initial costs, involves considering aspects such as long-term durability, maintenance requirements, and the total life cycle of the product. Investing in high-quality grating, though more costly at the outset, often results in savings by minimizing replacements and repairs over time, not to mention reducing potential hazards associated with product failure. As the demand and technology surrounding bar grating continue to evolve, staying informed about innovations in material science and manufacturing techniques can provide purchasers with a strategic advantage. Emerging technologies such as enhanced corrosion-resistant coatings or eco-friendly production processes not only offer functional benefits but can also align with broader organizational sustainability goals, indirectly influencing cost strategies. In conclusion, understanding bar grating costs requires a seamless blend of experience, expertise, and authoritative insight, grounded in trustworthiness concerning both product and supplier. By considering material type, manufacturing method, customization, and supplier credibility, purchasers can not only navigate the complexities of cost efficiently but also make informed decisions that yield long-term benefits both economically and functionally.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025