- אזור תעשייה, מדרום לאנפינג טאון, הנגשוי, הביי, סין.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  אנגלית

אנגלית  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- אנגלית

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

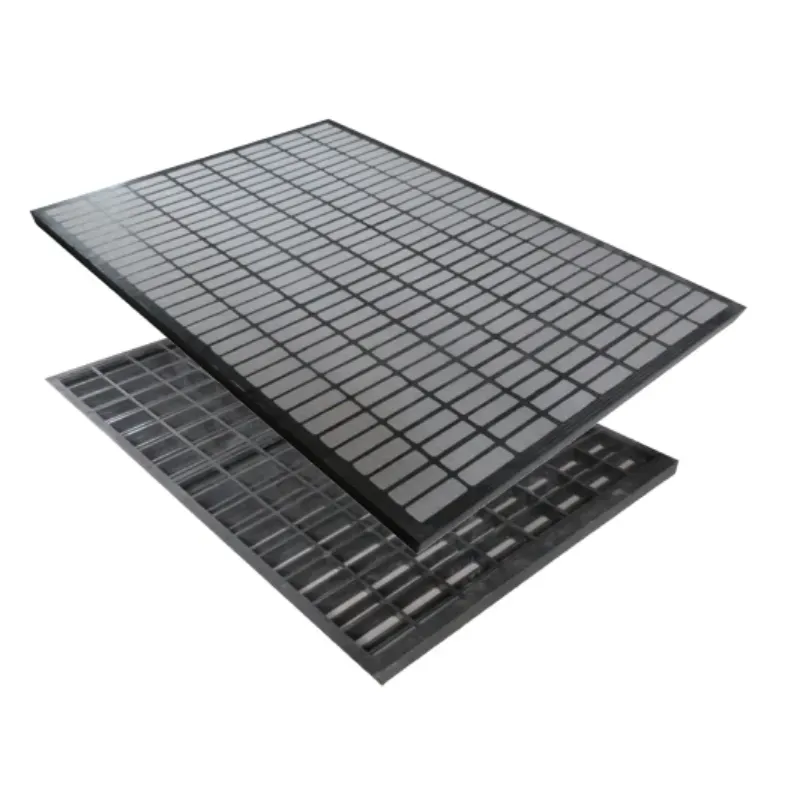

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening Power

In the demanding field of oil and gas exploration, the performance of your solid control system can define the success of the entire operation. Among all the components, the shale shaker screen stands as the frontline filter, playing a critical role in the fluid circulation process during drilling. For operators seeking reliable separation technology and long-term cost-efficiency, choosing the right shale shaker screen for sale is an investment in productivity, environmental compliance, and equipment longevity.

How the Shale Shaker Screen Enhances Oil Drilling Operations

A high-quality shale shaker screen is vital in the initial phase of solids control in oil drilling. As drilling fluid returns from the borehole, it contains a mixture of formation cuttings and other particulates. The shale shaker screen separates these solids from the fluid through vibratory motion, allowing clean mud to be recirculated back into the system while discarding the solids.

This process not only preserves expensive drilling fluids but also protects downstream equipment such as desanders, desilters, and centrifuges from wear. By maintaining the integrity of the drilling fluid, the shale shaker screen improves rate of penetration (ROP), enhances drill bit performance, and significantly reduces downtime. Selecting a premium shale shaker screen supplier ensures consistent particle removal and lower operational risk under extreme drilling conditions.

The Importance of Screen Layer Count in Shale Shaker Screens

The number of mesh layers used in a shale shaker screen directly impacts its efficiency, durability, and lifespan. Typically, single-layer screens are lightweight and suitable for large particle separation, while dual- or triple-layer screens offer finer filtration and extended durability through multi-stage particle interception.

A multi-layer shale shaker screen is designed to maintain flow rate while reducing the risk of clogging, as the top layer captures larger particles and the bottom layers handle finer debris. This distribution minimizes abrasion and prevents premature screen failure. Operators can tailor their screen selection based on the drilling formation and mud properties. When exploring shale shaker screen for sale options, multi-layer construction should be considered for high-performance wells, especially those requiring tighter solids control and longer operating intervals.

In addition, layer bonding techniques such as composite framing or high-tension adhesive welding are crucial for preventing delamination. That’s why a trusted shale shaker screen supplier always offers customizable layering options to match the physical demands of your site.

Grid Structure of the Shale Shaker Screen and Its Impact

While mesh count governs filtration precision, the grid structure determines the mechanical strength and vibration performance of a shale shaker screen. The internal support grid, typically made of steel or composite materials, provides the necessary tension to keep the mesh flat and taut during operation. A well-designed grid structure minimizes mesh flutter, improves solids conveyance, and extends the life of the screen.

Popular grid designs include rectangular and hexagonal patterns, each optimized for different flow and vibration characteristics. A tighter grid ensures more support across the mesh surface, reducing the chance of tearing or collapse during high-G operation. Conversely, more open grid structures promote higher flow capacity but may require reinforced frame construction.

For high-pressure drilling environments, choosing a shale shaker screen for sale with a reinforced steel frame and laser-cut support grid ensures consistent screening efficiency and reduces the likelihood of downtime due to mesh fatigue. Reputable shale shaker screen suppliers offer detailed specifications on grid design, allowing customers to match structural properties with site demands.

Balancing Cost and Quality: Understanding Shale Shaker Screen Price Factors

When considering the shale shaker screen price, it’s important to look beyond initial cost and evaluate the product’s long-term value. A lower upfront cost may mean shorter screen life, poor vibration handling, or less efficient solids separation. Instead, the total cost of ownership—including replacement frequency, downtime due to failure, and drilling fluid losses—should guide purchasing decisions.

High-performance shale shaker screens for sale may come with premium pricing, especially if they feature multi-layer mesh, corrosion-resistant frames, or proprietary grid reinforcement. However, these options pay off by extending runtime, increasing separation precision, and reducing fluid waste. Advanced screen materials such as stainless steel or composite frames also command higher prices but significantly improve ROI.

Reliable shale shaker screen suppliers will provide transparent pricing based on mesh type, frame material, size, and performance guarantees. Many also offer custom-built screens tailored to specific shaker models, further optimizing separation results.

Shale Shaker Screen FAQs

How does a shale shaker screen help improve drilling performance?

A shale shaker screen removes drilled solids from the returning mud, ensuring cleaner fluid for recirculation. This reduces equipment wear, improves drilling speed, and helps maintain fluid properties.

What’s the benefit of using multi-layer shale shaker screens?

Multi-layer shale shaker screens provide superior filtration and longer lifespan. Each layer captures different particle sizes, improving efficiency while protecting the screen from rapid wear.

How does the grid structure affect shale shaker screen performance?

The grid structure supports the mesh and influences vibration distribution. A strong, well-designed grid in a shale shaker screen reduces mesh damage and increases flow consistency.

Why do shale shaker screen prices vary so much?

Shale shaker screen price differences are due to mesh quality, number of layers, frame material, and durability. Premium screens offer longer service life and more efficient separation, saving money over time.

Where can I find a reliable shale shaker screen supplier?

A trusted shale shaker screen supplier will offer a range of API-compliant screens, custom configurations, transparent pricing, and ongoing technical support to suit different drilling requirements.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationחֲדָשׁוֹתAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyחֲדָשׁוֹתAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsחֲדָשׁוֹתAug.08,2025

-

Precision Strength with Welded Steel Bar GratingחֲדָשׁוֹתAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsחֲדָשׁוֹתAug.08,2025

-

Maximize Performance with Steel Walkway GratingחֲדָשׁוֹתAug.08,2025