- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

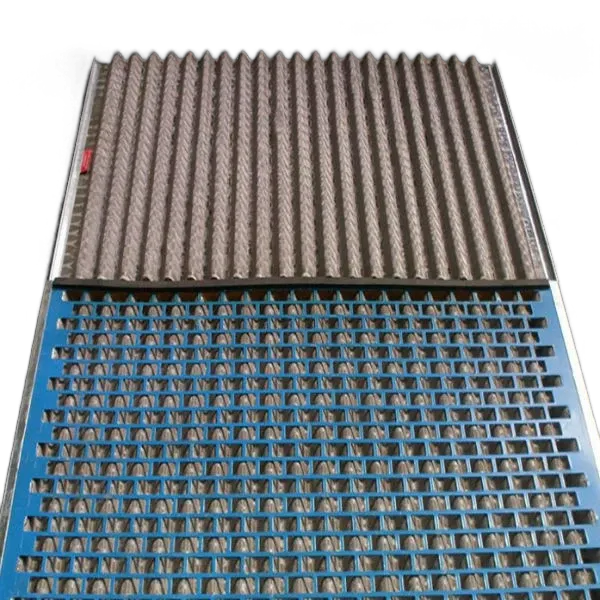

galv grating

Understanding Galvanized Grating A Comprehensive Overview

Galvanized grating is a crucial component utilized in various industrial and commercial applications, offering strength, durability, and corrosion resistance. Comprising steel bars welded together to form a grid, galvanized grating finds its niche in flooring, walkways, and platforms where safety and reliability are paramount. In this article, we will explore the manufacturing process, benefits, applications, and maintenance of galvanized grating.

The Manufacturing Process

The production of galvanized grating begins with selecting high-quality steel bars. These bars are often hot-rolled and come in various sizes and thicknesses, depending on the application requirements. The primary steps involved in manufacturing galvanized grating include

1. Welding The steel bars are arranged in a grid pattern and welded together at their intersections. This creates a strong structural element that is capable of bearing heavy loads.

2. Galvanization After welding, the grating is subjected to a galvanization process. This involves dipping the fabricated grating into a molten zinc bath, which coats the steel with a layer of zinc. This process not only provides corrosion resistance but also enhances the product's longevity.

3. Finishing Once galvanized, the grating may undergo further processing such as cutting to size, drilling holes for mounting, or applying additional finishes to improve aesthetics or slip resistance.

Benefits of Galvanized Grating

Galvanized grating offers a myriad of benefits, making it a preferred choice in many industries. Some of the key advantages include

- Corrosion Resistance The layer of zinc acts as a barrier that protects the underlying steel from moisture, which is essential in environments exposed to chemicals or high humidity.

- Strength and Load Capacity Galvanized grating is designed to support heavy loads, making it ideal for industrial and commercial use. The welded structure provides exceptional strength while maintaining a lightweight profile.

- Low Maintenance Once installed, galvanized grating requires minimal maintenance. The protective zinc coating prevents rust and deterioration, ensuring long-lasting durability.

galv grating

- Safety With options for slip-resistant surfaces, galvanized grating enhances safety in high-traffic areas, reducing the risk of slips and falls.

- Versatile Applications Due to its customizable nature, galvanized grating can be employed in a wide range of settings, from walkways to drainage covers and platform floors.

Applications

Galvanized grating is widely used across various industries due to its durability and versatility. Some common applications include

- Industrial Facilities In factories and warehouses, galvanized grating serves as walkways, platforms, and loading docks, allowing for efficient movement of personnel and equipment.

- Wastewater Treatment Plants Its resistance to harsh chemicals makes it suitable for use in treatment facilities where exposure to moisture and corrosive substances is common.

- Power Plants Galvanized grating is often used in power generation facilities for stairways, platforms, and catwalks, providing safe access to equipment.

- Commercial Buildings In commercial spaces, it is utilized for ventilation grates, mezzanine flooring, and outdoor walkways, contributing to both functionality and aesthetics.

Maintenance Considerations

While galvanized grating is designed to be low maintenance, regular inspections are advisable to ensure its integrity. Cleaning should be conducted periodically to remove debris and corrosive agents, particularly in areas with high foot traffic or exposure to chemicals. Inspecting for damage, such as cracks or loosening, ensures that safety standards are upheld.

Conclusion

In conclusion, galvanized grating is an essential element in various sectors, known for its robustness and resistance to corrosion. With a straightforward manufacturing process and numerous benefits, it remains a favored choice in construction and industrial applications. By understanding its features and maintenance practices, users can fully leverage the advantages that galvanized grating offers, ensuring safe and efficient operations in their respective fields.

-

Upgrade Your Industrial Operations with Durable Steel GratingNewsJul.21,2025

-

Transform Your Flooring Solutions with Quality Floor GratingNewsJul.21,2025

-

Top-Quality Shale Shaker Screens for Your Drilling NeedsNewsJul.21,2025

-

High-Quality Steel Grating for All Your Industrial NeedsNewsJul.21,2025

-

Explore the Durability and Versatility of Galvanized Steel GratingNewsJul.21,2025

-

Ensure Maximum Safety with Premium Safety NetsNewsJul.21,2025