- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

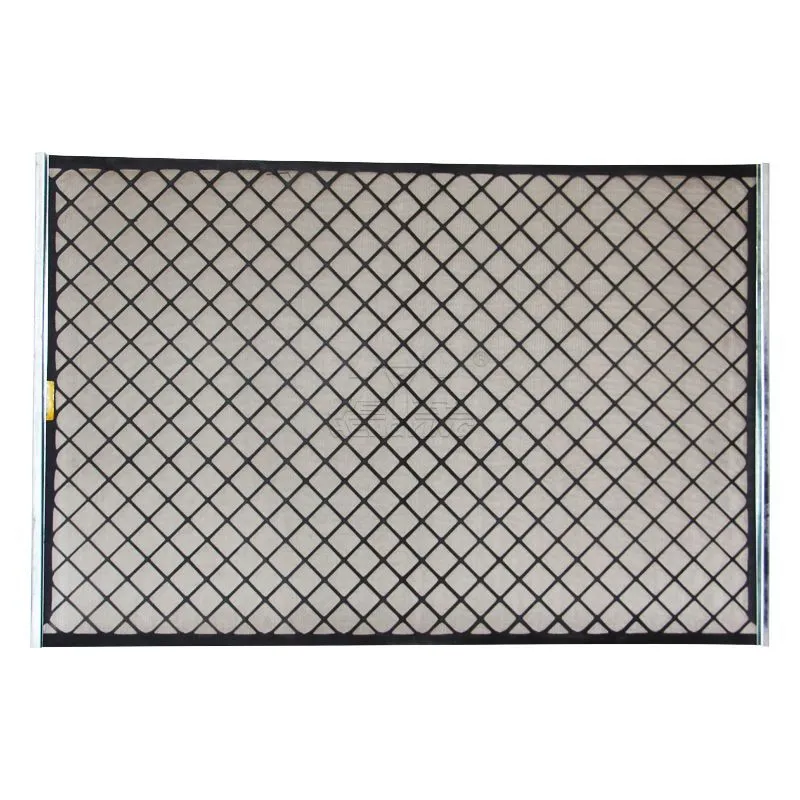

concrete weight coating mesh

The Importance and Application of Concrete Weight Coating Mesh in Pipeline Industries

Concrete weight coating (CWC) is an essential process employed in the pipeline industry to provide weight, protection, and stability to underwater pipelines. Increasingly, combining advanced materials like concrete with innovative mesh structures has highlighted the significant role of concrete weight coating mesh. This article explores the importance, applications, and benefits of concrete weight coating mesh in various sectors.

Understanding Concrete Weight Coating

Concrete weight coating involves the application of concrete to the outer surface of a pipeline. The primary reason for this practice is to add weight, which helps to keep the pipeline submerged and prevents it from floating up due to buoyancy forces in marine environments. The weight coating also protects the pipeline from external damage, such as abrasions from seabed movements or contact with other marine structures.

The mesh in concrete weight coating serves a critical role in enhancing the structural integrity of the coating itself. It acts as a reinforcement, improving the load-bearing capacity and durability of the concrete layer. Often made from high-tensile steel or polymer materials, this mesh not only provides strength but also ensures that the concrete adheres well to the pipeline surface.

Applications of Concrete Weight Coating Mesh

Offshore Pipelines

One of the primary applications of concrete weight coating mesh is in offshore pipelines that transport oil, gas, and other resources across challenging marine environments. The mesh reinforces the concrete, which keeps the pipeline stable on the seabed, mitigating the risks of movement caused by currents, storms, or seismic activities.

Submarine Cable Protection

In addition to pipelines, concrete weight coating mesh is also used for protecting submarine cables. The addition of weight prevents the cables from floating, minimizing the risk of damage from environmental factors. The mesh provides a durable layer that shields the cables from mechanical stresses and external impacts.

concrete weight coating mesh

Industrial Applications

Beyond marine uses, concrete weight coating mesh finds applications in various industrial sectors. For instance, in the construction of heavy machinery foundations or in building support systems, the added weight and stability provided by concrete weight coating mesh can enhance the overall performance of the structure.

Benefits of Concrete Weight Coating Mesh

1. Enhanced Durability The integration of mesh within concrete coating significantly extends the lifespan of pipelines and cable systems, particularly in adverse conditions. 2. Increased Stability The additional weight helps stabilize underwater structures, ensuring they resist natural forces without shifting or floating.

3. Cost-Effectiveness By preventing damage and reducing maintenance needs, concrete weight coating mesh can lead to substantial cost savings over time.

4. Versatility The use of various materials in manufacturing meshes allows for customization based on specific project needs, including flexibility in weight and dimension.

5. Safety Considerations The reinforcement provided by the mesh reduces potential risks associated with pipeline failures, thus enhancing safety for marine and industrial applications.

Conclusion

Concrete weight coating mesh is a critical component in the construction and maintenance of both underwater pipelines and other industrial structures. Its ability to enhance the durability, stability, and overall performance of weight coatings makes it indispensable in the pipeline industry. As demand for more sustainable and resilient infrastructure grows, the use of advanced materials and reinforced systems like concrete weight coating mesh will continue to expand. By ensuring that pipelines remain submerged and protected from environmental challenges, this innovative approach contributes to the efficient, safe, and reliable transport of essential resources worldwide.

With ongoing advancements in material science and engineering techniques, the future of concrete weight coating mesh looks promising. Industries that rely on underwater infrastructure can anticipate even greater levels of protection and efficiency, paving the way for more robust marine operations. As the sector evolves, investment in new technologies and materials will be critical for addressing future challenges and ensuring sustainable development in marine resource management.

-

Welded Steel Bar Grating: The Strongest Choice for Industrial FlooringNewsMay.21,2025

-

Steel Grating for Sale: The Ultimate Anti-Slip SolutionNewsMay.21,2025

-

Steel Frame Shaker Screens: Unmatched Durability for Demanding OperationsNewsMay.21,2025

-

Shaker Screens: Your Ultimate Solution for Oil & Gas FiltrationNewsMay.21,2025

-

Press Locked Steel Grating: The Smarter Choice for Heavy-Duty FlooringNewsMay.21,2025

-

Helicopter Deck Safety Nets: Protect Your Crew and EquipmentNewsMay.21,2025