- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

bar grating cost

Understanding the Costs of Bar Grating A Comprehensive Overview

Bar grating is a versatile and widely used product in various industries, including construction, manufacturing, and transportation. It provides a durable and effective solution for flooring, walkways, platforms, and other applications where strength and safety are paramount. However, as with any material, understanding the associated costs of bar grating is essential for making informed purchasing decisions.

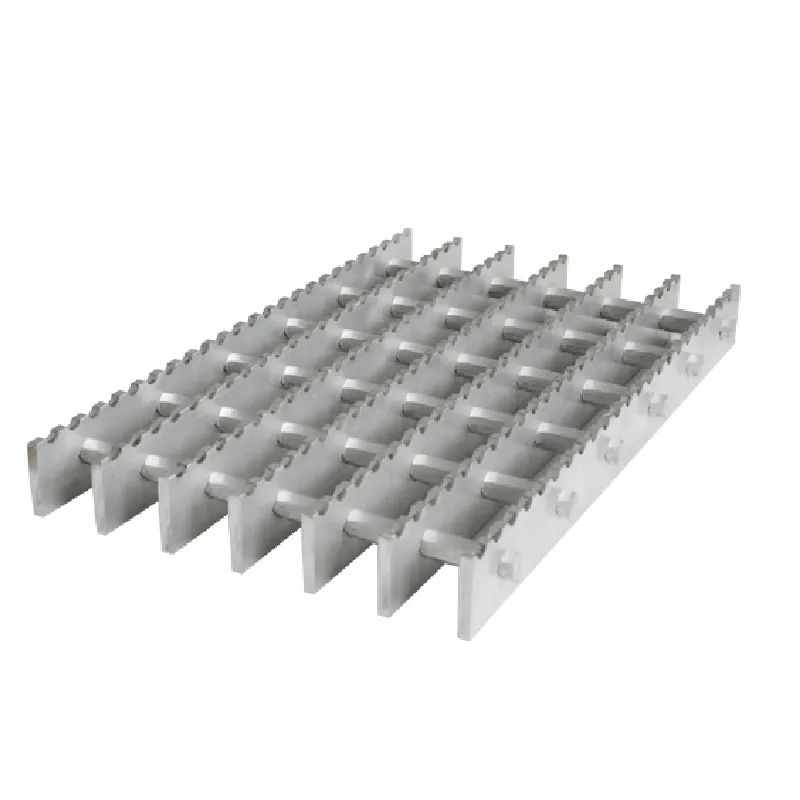

What is Bar Grating?

Bar grating consists of a series of parallel bars that are joined together to create a sturdy surface. The bars can be made from different materials, including steel, aluminum, and fiberglass, each offering distinct advantages based on the intended application. Bar grating is available in various styles and sizes, such as welded, press-locked, and swaged, allowing for customization based on specific project needs.

Factors Influencing Bar Grating Costs

1. Material Type The choice of material is one of the primary factors affecting the cost of bar grating. Steel, for instance, is typically more affordable than aluminum. However, aluminum grating offers advantages such as resistance to corrosion and lighter weight, which may justify its higher cost in certain applications. Fiberglass grating, while often more expensive upfront, can be beneficial in corrosive environments where longevity and maintenance considerations make it a cost-effective choice over time.

2. Grating Style and Configuration The design and configuration of the grating also significantly impact its cost. Standard welded grating tends to be more economical, while more complex configurations such as swaged bar grating may incur higher manufacturing costs. Custom designs may lead to increased costs due to specialized tooling and production processes.

3. Thickness and Load Requirements The thickness of the bars and the load-bearing requirements of the grating can influence the price. Heavier, thicker bars capable of withstanding substantial loads will generally cost more than lighter options. When planning a project, it's vital to assess the anticipated load to ensure that the selected grating can meet safety and performance standards without unnecessary expenditures.

bar grating cost

4. Surface Treatments Bar grating can be treated with various finishes to enhance durability, slip resistance, and aesthetics. Galvanizing, for example, is a common surface treatment that protects steel from rust and corrosion but adds to the overall cost. Additionally, options like powder coating can provide both protection and color, influencing pricing further.

5. Quantity and Bulk Discounts The overall quantity of bar grating required for a project can significantly affect per-unit costs. Obtaining grating in bulk often allows businesses to negotiate better prices. If you're considering a large project, collaborating with suppliers to explore bulk order discounts can lead to substantial savings.

6. Transportation and Installation Costs Transportation costs can vary, depending on the location and the volume of the order. Additionally, installation can add to the overall cost of bar grating. It’s essential to factor in these expenses, especially for larger installations or those in remote locations.

Cost Comparison and Budgeting

When budgeting for a bar grating project, conducting a thorough cost comparison among different suppliers is crucial. Prices can vary substantially between manufacturers based on the factors outlined above. It’s advisable to gather quotes and consider the total cost of ownership, not just the initial purchase price.

Conclusion

In conclusion, understanding the costs associated with bar grating involves examining various factors, including material type, design, thickness, finishing options, quantity, and additional expenses such as transportation and installation. By taking the time to assess these variables, businesses can make informed decisions that meet their functional needs while staying within budget constraints. Investing in the right bar grating solution can ultimately enhance safety, durability, and efficiency in various applications, making it a worthwhile consideration for any project.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025