- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

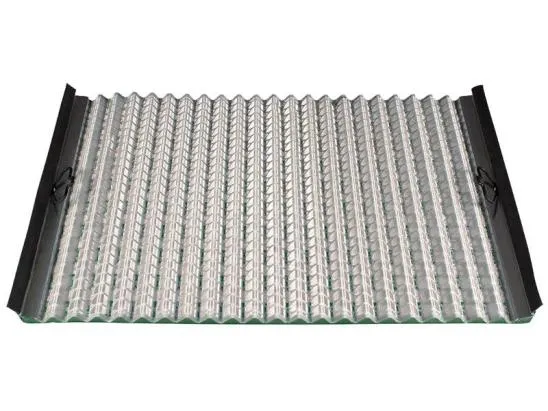

Shale Shaker Screen-Anping Hangshun|Drilling Fluid Separation,API RP 13C

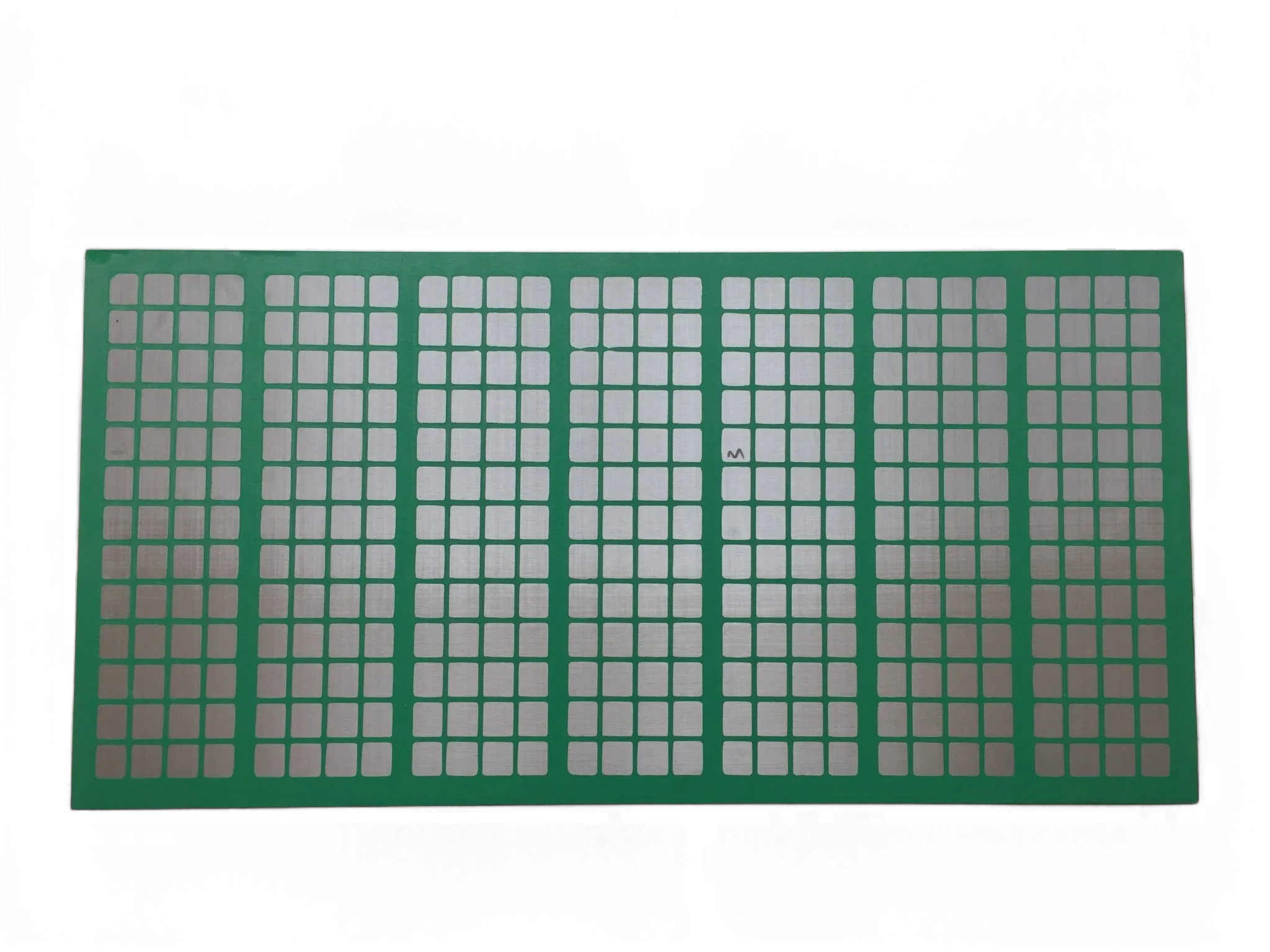

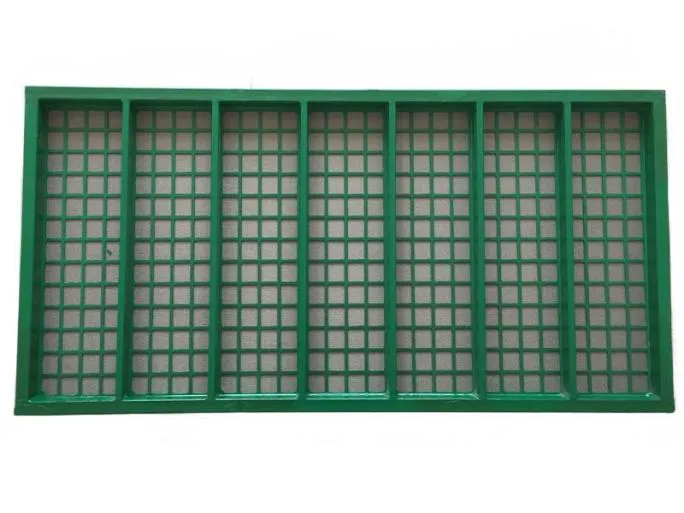

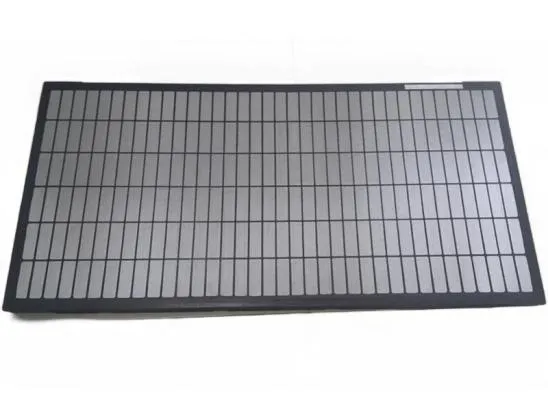

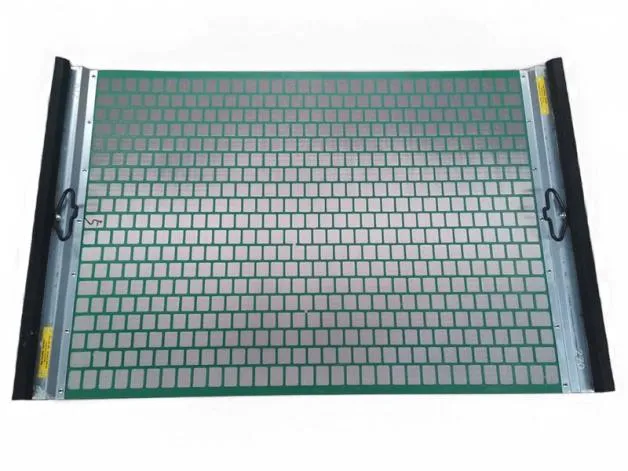

Introduction to Shale Shaker Screens

Shale shaker screens are critical components in the drilling industry, designed to separate solid cuttings from drilling fluids (mud) during oil and gas extraction processes. These screens are typically made of woven metal mesh, often with dual or triple layers, to ensure high filtering accuracy. As part of a shale shaker system, they play a vital role in maintaining the efficiency of drilling operations by capturing solid particles while allowing excess mud to return to the tank. Learn more about shale shaker screen mesh.

Key Features and Advantages

The shale shaker screen is engineered to deliver exceptional performance in demanding drilling environments. Its design incorporates advanced materials and manufacturing techniques to ensure durability and efficiency. Below are the core features that make this product a preferred choice in the industry:

- High Strength and Load Capacity: Constructed from stainless steel or carbon steel, the screen can withstand heavy drilling fluid loads without deformation.

- Superior Filtering Accuracy: Multi-layered mesh configurations (dual or triple) ensure precise separation of solid particles, reducing contamination in drilling fluids.

- Wear and Corrosion Resistance: Surface treatments like coatings enhance longevity, even in harsh chemical environments.

- Flexibility and Adaptability: Available in various types (steel frame, composite, wave, hook strip) to suit different shale shaker models and drilling conditions.

- Easy Installation and Maintenance: Designed for quick replacement, minimizing downtime during operations.

For instance, wave screens are known for their high processing efficiency, while steel frame screens offer the highest weight-bearing capacity. Explore shale shaker screen price options to find the ideal solution for your needs.

Technical Specifications

| Specification | Details |

|---|---|

| Material | Stainless steel, carbon steel |

| Surface Treatment | Coating (black, green, blue; customizable) |

| Production Process | Weaving and perforating |

| Type | Steel or composite frame screen, hook strip screen, wave screen |

| Standards | ISO 13501, API RP 13C, GBT 11648, GBT 11650 |

Applications in Drilling and Environmental Industries

The shale shaker screen is widely used in multiple sectors, including:

- Oil and Gas Drilling: Essential for separating cuttings from drilling mud in rotary and directional drilling operations.

- Coal Bed Methane and Shale Gas Drilling: Ensures efficient mud recycling and environmental compliance.

- Non-Excavation Horizontal Directional Drilling: Reduces downtime by maintaining clean drilling fluids.

- Environmental Protection: Used in sludge treatment and water purification systems to remove solid contaminants.

For example, composite frame shale shaker screens are ideal for applications requiring both durability and flexibility. Discover more about shale shaker screen factory solutions tailored to your industry.

Company Background: Anping County Hangshun Wire Mesh Manufacture Co., Ltd.

As a leading manufacturer in the wire mesh industry, Anping County Hangshun Wire Mesh Manufacture Co., Ltd. specializes in producing high-quality shale shaker screens and related products. With a focus on precision engineering and adherence to international standards, the company has established itself as a trusted supplier for drilling and environmental applications. Their commitment to innovation and quality ensures that their products meet the rigorous demands of modern industrial environments.

For more information about their shale shaker screen factory, visit https://www.hfpetromesh.com/shale-shaker-screen.html.

Industry Standards and Compliance

The shale shaker screen complies with globally recognized standards such as ISO 13501 and API RP 13C, ensuring reliability and performance in critical applications. These standards, often referenced by organizations like the National Institute of Standards and Technology (NIST), set benchmarks for material quality and manufacturing processes. By adhering to these guidelines, Anping County Hangshun Wire Mesh Manufacture Co., Ltd. guarantees that their products meet the highest levels of industrial safety and efficiency.

References:

NIST. (n.d.). National Institute of Standards and Technology. Retrieved from https://www.nist.gov/

-

The Versatility of Steel Walkway GratingNewsAug.07,2025

-

The Benefits of Galvanized Steel Grating for Your ProjectsNewsAug.07,2025

-

Shaker Screens: The Ultimate Solution for Your Drilling NeedsNewsAug.07,2025

-

Perimeter Safety Net: An Essential Solution for Helipad SafetyNewsAug.07,2025

-

Enhance Safety and Efficiency with Steel Walkway GratingNewsAug.07,2025

-

Discover Exceptional Steel Grating for SaleNewsAug.07,2025