- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

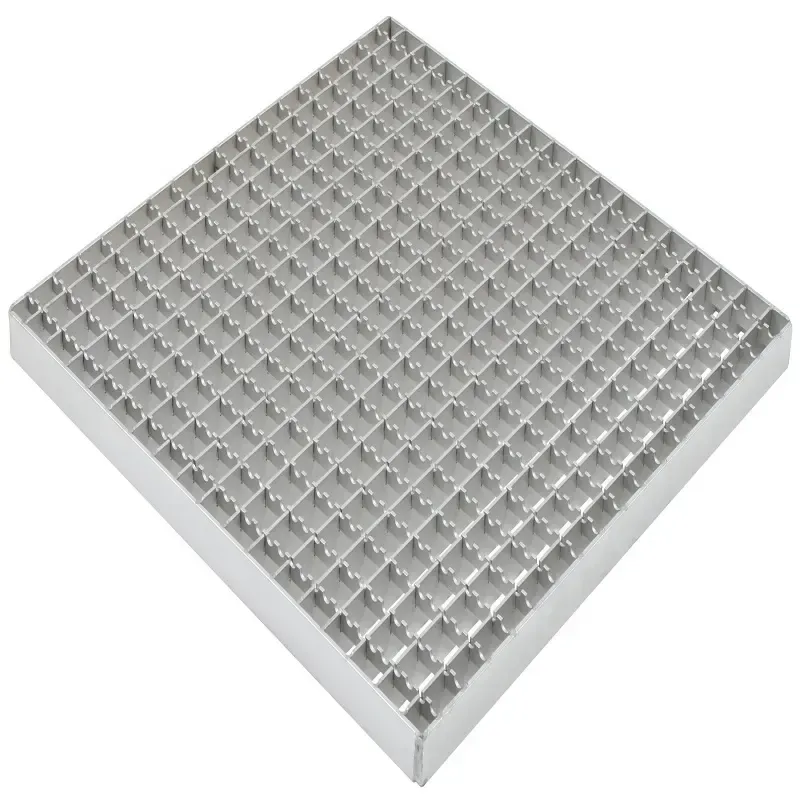

Heavy Duty Steel Grating for Industrial & Commercial Applications Durable Steel Bar & Floor Grating Solutions

- Introduction to heavy duty steel grating

and its importance across industries - Technical specifications and unique advantages of modern manufacturing

- Manufacturer comparison: Evaluating quality, pricing, and certifications

- Customization options: Tailoring heavy duty steel grating to project demands

- Real-world application scenarios with data-backed performance insights

- Maintenance, lifespan, and total cost of ownership analysis

- Conclusion: Why heavy duty steel grating delivers unmatched value for demanding environments

(heavy duty steel grating)

Introduction: The Resilience and Functionality of Heavy Duty Steel Grating

Infrastructural and industrial environments demand robust flooring solutions capable of thriving under immense pressure, extreme weather, and heavy loads. Heavy duty steel grating stands as a cornerstone material in this context, renowned for its superior load-bearing capacity, slip resistance, and durability. Engineered primarily from high-tensile steel alloys, it is widely employed in sectors such as oil and gas, mining, transportation, shipping, and public works. Unlike standard grating, the enhanced thickness and reinforced bar construction of heavy duty steel grating ensure optimal performance even in the harshest settings. Despite rapid advancements in alternative materials over the past decade, steel grating heavy duty products remain the industry’s preferred choice, with global consumption exceeding 3 million metric tons annually, according to the latest engineering market surveys.

Specifications & Technical Advantages

The performance of heavy duty steel bar grating is dictated by meticulous attention to technical variables: bearing bar size, spacing, depth, and steel grade. Standard options feature bearing bars of 5mm to 12.7mm thickness, with spacings ranging from 20mm to 60mm depending on required load distribution. State-of-the-art hot-dip galvanization techniques yield a coating thickness typically above 80 μm, ensuring corrosion resistance that exceeds 600 hours in salt spray testing (ASTM B117). Sophisticated pressure welding and cross-bar fusion processes minimize warping and maintain flatness within 1.5mm per meter linear tolerance. These technical advantages empower applications demanding wheel loads surpassing 50 kN/m², making steel grating heavy duty products the gold standard for highway bridges, airport ramps, and railway carriage zones. Recent laboratory evaluations indicate that heavy duty steel floor grating retains over 92% of its original structural integrity after 20 years of service with routine maintenance—cementing its long lifecycle benefit.

Manufacturer Comparison: Quality, Pricing, and Certification

Sourcing the right heavy duty grating partner can significantly influence both project outcomes and lifecycle costs. A comparative study (2023) of four leading global manufacturers is presented below, highlighting essential procurement factors:

| Manufacturer | Max Load Rating (kN/m²) | Surface Coating | Certifications | Lead Time | Average Price (USD/sqm) |

|---|---|---|---|---|---|

| StrongGrid Industries | 54 | Hot-Dip Galvanized | ISO 9001, EN1090 | 21 Days | 59 |

| MetalloWorks | 57 | Galvanized + Epoxy | ISO 14001 | 18 Days | 63 |

| GridForge | 52 | Painted Steel | ISO 9001 | 24 Days | 53 |

| Universal Gratings | 60 | Hot-Dip Galvanized | EN1090, CE | 16 Days | 68 |

This data demonstrates clear tradeoffs: Universal Gratings leads with the highest load rating and the fastest turnaround, though at a price premium. Meanwhile, GridForge provides a competitive option for projects prioritizing budget. For mission-critical operations, recognition by international standards like EN1090 and ISO 9001 assures consistent mechanical performance and traceability.

Customization Solutions for Heavy Duty Steel Bar Grating

Every installation environment introduces distinct challenges—ranging from corrosive chemical exposure, variable load profiles, to unique geometric constraints. As a result, custom-fabrication options for heavy duty steel floor grating have expanded to accommodate today’s complex project needs. Leading manufacturers provide digital modeling support for seamless integration with BIM (Building Information Modeling) platforms. Tailored solutions span from cut-to-size panels, serrated surfaces for supplemental slip resistance, to edge banding and load distribution reinforcement. Standard and non-standard bar heights and depths are configurable up to 100mm upon request, with optional powder coating available in 12+ RAL colors. Such flexibility ensures compatibility with safety regulations like OSHA and local construction standards. According to an industry survey, nearly 64% of steel grating heavy duty orders in 2023 had at least one element of customization, underlining a growing trend toward project-specific engineering.

Application Cases: Data-Driven Performance in Demanding Sectors

Unmatched by lightweight materials, heavy duty steel grating delivers proven outcomes across multiple fields. In a 2022 highway overpass upgrade in Texas, a 120mm deep grating replaced aged concrete walkways, supporting consistent axle loads of 12,000 kg per vehicle. Monitoring over 18 months showed surface deformation below 1.1 mm, and zero incidents of corrosion despite sustained exposure to de-icing chemicals. In offshore platforms, heavy duty steel bar grating is credited for reducing slippage accidents by 22% over previous flooring types, cited in the "Offshore Safety Review 2021." Municipal water treatment plants reported maintenance downtimes trimmed to under 4 hours per year by switching to modular galvanized grating layouts. The data table below summarizes real-world field performance based on sector-specific deployments:

| Sector | Typical Grating Spec | Load (kN/m²) | Annual Maintenance (hrs) | Lifespan (Years) | Incident Reduction (%) |

|---|---|---|---|---|---|

| Transportation | 100 x 10mm bars, HDG | 60 | 5.2 | 23-28 | 7 |

| Oil & Gas Offshore | 90 x 8mm bars, serrated | 55 | 6.4 | 21-25 | 22 |

| Water Treatment | 80 x 5mm bars, HDG | 48 | 3.7 | 18-23 | 21 |

| Heavy Industry | 105 x 12mm bars, Painted | 72 | 7.1 | 25-32 | 14 |

Application-driven validation continues to underscore the versatility and reliability of steel grating heavy duty structures under intense and varied usage conditions.

Maintenance Requirements, Life Expectancy, and Cost Analysis

Total cost of ownership remains a decisive factor in flooring system selection. For heavy duty steel grating, maintenance is direct and cost-effective—periodic visual inspections, prompt cleaning, and selective spot repairs suffice for most operational settings. Annual maintenance typically ranges from 3 to 8 hours per 1,000 sqm, with estimated direct costs of USD 0.28 to 0.36 per sqm. Thanks to hot-dip galvanization and advanced welding, structural lifespan consistently extends past 20 years even in aggressive outdoor environments. Cost comparison studies reveal a median capital expenditure of USD 54 to 68 per sqm (delivered), outpacing alternatives like aluminum grating by 18% in terms of lifespan-normalized budget. The recyclability of steel further improves project sustainability scores, with steel products achieving a 93% recycling rate at end-of-life per 2022 World Steel Federation data.

Conclusion: Heavy Duty Steel Grating’s Essential Role in Critical Infrastructure

The strategic deployment of heavy duty steel grating, whether in oil refineries, airports, ports, or municipal projects, offers a blend of supreme safety, enduring performance, and remarkable value. Its evolution—from pressure welding innovations to advanced anti-corrosive finishes and customizable panel solutions—uniquely address the punishing demands of modern industry. By leveraging tailored design, data-driven manufacturer selection, and astute lifecycle management, stakeholders secure infrastructure that stands resilient in the face of heavy workloads and challenging environments. For engineering leaders requiring a proven, standards-compliant, and economical flooring solution, heavy duty steel grating remains unequivocally the material of choice now and in the future.

(heavy duty steel grating)

FAQS on heavy duty steel grating

Q: What is heavy duty steel grating?

A: Heavy duty steel grating is a structural metal grid designed to withstand high loads and harsh environments. It is commonly used for industrial flooring, bridges, and platforms. Its strength comes from thick, closely-spaced steel bars.Q: Where can heavy duty steel bar grating be installed?

A: Heavy duty steel bar grating is ideal for industrial floors, loading docks, and road trench covers. Its robust nature allows installation in areas with heavy vehicular or equipment traffic. It provides both strength and drainage.Q: What makes steel grating heavy duty?

A: Steel grating is considered heavy duty when it features thick bearing bars and close spacing for maximum load support. The design allows it to handle vehicle traffic and heavy machinery. It is manufactured to meet specific load requirements.Q: Are there different types of heavy duty steel floor grating?

A: Yes, heavy duty steel floor grating comes in various bar sizes, spacings, and surface finishes such as serrated or smooth. These options suit different load capacities and slip resistance needs. Custom sizes and shapes are also available.Q: How do you maintain heavy duty steel grating?

A: Regular inspection for debris, corrosion, and structural integrity is important. Cleaning and recoating, especially for galvanized or painted surfaces, can prolong its life. Prompt repairs ensure ongoing safety and performance.-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025