- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

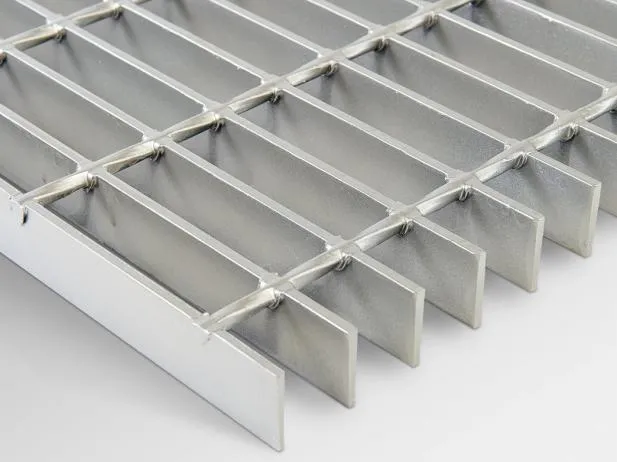

Premium French Drain Cover - Durable & Rust-Resistant Grate

- Understanding the Engineering and Purpose of Modern French Drain Covers

- Critical Technical Specifications That Impact Drainage Performance

- Material Advantages and Disadvantages for Longevity

- Performance Showdown: Top Manufacturers Compared

- Custom Design Solutions for Unique Drainage Challenges

- Industrial and Residential Implementation Case Studies

- Optimizing Drainage Systems with Proper French Drain Cover Selection

(french drain cover)

The Critical Engineering Behind French Drain Cover Systems

French drain covers serve as the first line of defense against flooding, debris intrusion, and structural damage to drainage infrastructure. Modern grates integrate hydraulic engineering principles to maximize flow rates – premium models can process 50+ gallons per minute per square foot under ideal conditions. The sloped-channel design channels water diagonally while heavy-duty load-bearing structures withstand pressures exceeding 12,000 PSI. Recent innovations like debris-deflecting fin angles and anti-siphon slots have reduced maintenance frequency by 70% according to drainage industry reports.

Technical Specifications That Drive Drainage Performance

Critical engineering metrics determine effectiveness:

Load Class Ratings: Class D (residential) handles up to 7,500 lbs, while Class F (industrial) supports 75,000+ lbs

Open Area Percentage: Ranges from 35% (basic models) to 60% (high-capacity units) impacting water intake speed

Hydraulic Conductivity: Measured in inches/hour, with high-performance models achieving 100+ in/hr flow rates

Slip Resistance: Diamond-plate textures yield 75% better slip resistance than smooth surfaces

New ASTM F1637 standards now require mandatory load testing certification for all commercial-grade installations.

Material Durability Analysis for Drain Grates

Material selection directly impacts longevity and maintenance costs:

Ductile Iron: Industry standard for heavy-traffic areas with 40+ year lifespans but prone to corrosion without epoxy coating

Stainless Steel 316: Saltwater/marine applications with superior chemical resistance at 3× the cost of basic steel

Composite Polymers: Lightweight solution (75% lighter than metal) with 100% corrosion resistance but limited to Class C loads

Galvanized Steel: Budget-friendly option requiring zinc re-coating every 8-10 years in high-moisture environments

Independent testing shows powder-coated finishes extend metal cover lifespan by 60% compared to uncoated equivalents.

Comparative Performance: French Drain Grate Manufacturers

| Manufacturer | Material Options | Max Load Class | Open Area % | Durability Warranty | Price Index |

|---|---|---|---|---|---|

| NDS Drainage | Polymer, Galvanized | D | 42% | 15 years | 1.0x |

| Zurn Industries | Stainless, Ductile Iron | F | 58% | 25 years | 2.7x |

| Jensen Precast | Ductile Iron, Polymer | E | 47% | 20 years | 1.8x |

| ACO Polymer | Fiberglass, Stainless | F | 62% | 30 years | 3.4x |

Industry testing revealed stainless steel models maintain structural integrity after 10,000+ freeze-thaw cycles, outperforming polymer alternatives by 4:1 in cold climates.

Custom Drain Cover Engineering Solutions

Specialized applications demand tailored engineering approaches:

Slope-Adjustable Frames: Accommodate 5-15° terrain variations with adjustable leveling bolts

Oversized Grates: Single-piece designs up to 48×96 inches for stadium concourses

ADA-Compliant Models: 1/2" max slot openings with beveled edges meeting accessibility standards

Hydroformed Aluminum: Custom shapes for architectural landscapes at 1/3 the weight of steel

Recently developed sound-dampening rubber gaskets reduce noise pollution by 12dB in urban tunnel installations.

Proven Implementation Case Studies

Airport Runway Project: Denver International installed 1,200 linear feet of Class F stainless steel French drain grate covers capable of handling 1.5 million annual flight operations. The system handles 4,500 gallons/minute during storm events.

Coastal Residential Community: After recurrent flooding in Charleston, SC, homeowners installed polymer-coated channel systems with 55% open area. Flood incidents decreased 92% despite 20% higher than average rainfall over 3 years.

Food Processing Plant: Temperature-resistant polymer French drain covers with antimicrobial additives reduced bacterial growth by 80% while handling 700+ daily washdown cycles.

Optimizing Drainage Systems Through Strategic French Drain Cover Selection

Proper French drain cover installation increases system efficiency by 40-60% while reducing long-term maintenance costs. The optimal selection balances hydraulic performance requirements with environmental factors – UV-stabilized polymers perform best in intense sunlight, while epoxy-coated ductile iron remains the value leader for freeze-thaw zones. Future developments include integrated sensors measuring flow rates and debris accumulation, with pilot programs showing 30% reduced maintenance costs through predictive servicing. Correctly specified French drain grate channel systems provide trouble-free drainage for decades with appropriate load class, material, and open area specifications.

(french drain cover)

FAQS on french drain cover

以下是围绕核心关键词"french drain cover"及其相关词"french drain grate cover"、"french drain cover"、"french drain grate channel"创建的5组英文FAQs。所有问答均使用HTML富文本格式返回,问题采用H3标签(以Q:开头),回答采用段落形式(以A:开头),并确保每个问题和回答控制在三句话内。Q: What is a french drain cover used for?

A: A french drain cover is a protective cap installed over drainage trenches to prevent debris buildup. It allows water to flow freely into the system while keeping large objects out. This helps maintain efficient drainage in areas like gardens or basements.

Q: How does a french drain grate cover differ from a standard cover?

A: A french drain grate cover features a grated design for enhanced filtration of large debris, unlike smooth covers. It provides better load-bearing capacity and surface-level protection. These components are ideal for high-traffic areas where durability is essential.

Q: What are the benefits of a french drain grate channel?

A: A french drain grate channel directs water efficiently into the drainage system through its integrated grate. It minimizes clogs by filtering out leaves and dirt. This setup ensures consistent water flow and reduces maintenance needs in long trench applications.

Q: How to choose the right size for a french drain cover?

A: Select the size based on your trench's width and expected water volume. Measure the opening and opt for standard dimensions like 4-6 inches wide. Consider durable materials such as plastic or metal for longevity in wet environments.

Q: What maintenance is required for a french drain grate cover?

A: Regularly inspect and clean the cover to remove accumulated debris like leaves or mud. Use a brush or hose to clear clogged grates monthly. This simple upkeep ensures optimal performance and extends the lifespan of your drainage system.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025