- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

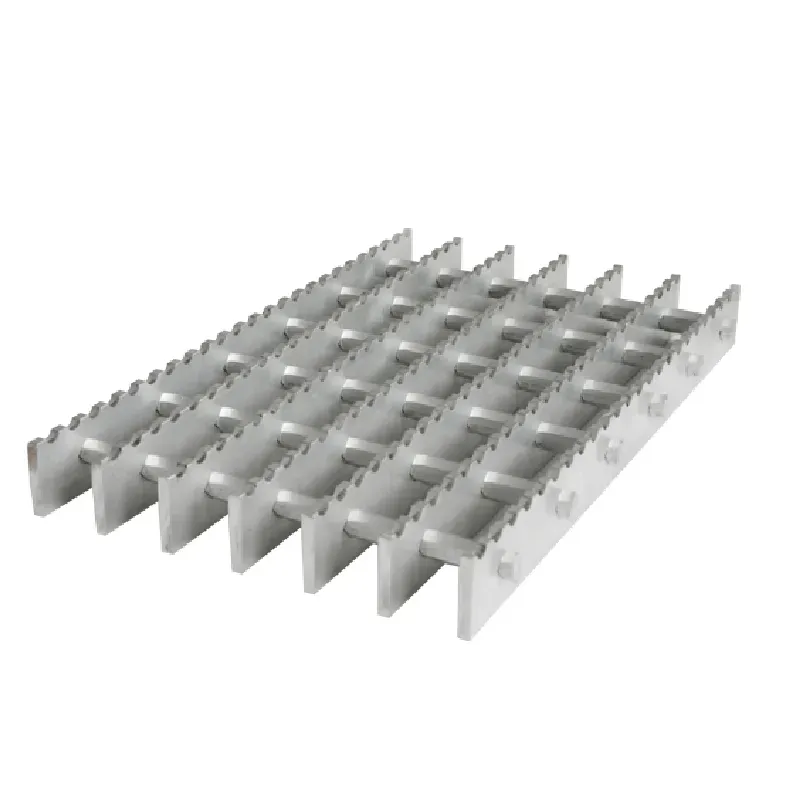

welded steel grating

The Importance of Welded Steel Grating in Modern Construction

Welded steel grating is a versatile and durable material widely used in various construction and industrial applications. Characterized by its open structure and high strength, welded steel grating has become a preferred choice for flooring, walkways, and platforms across a myriad of industries, including manufacturing, agriculture, and transportation.

Definition and Composition

Welded steel grating is comprised of longitudinal and transverse bars that are welded together at their intersection points, forming a grid-like structure. This configuration not only provides exceptional strength and stability but also allows for easy drainage and ventilation, making it suitable for many outdoor and industrial environments. The bars are typically made of carbon steel, stainless steel, or aluminum, ensuring a combination of robustness and resistance to environmental factors.

Key Benefits

1. Strength and Load-Bearing Capacity One of the most significant advantages of welded steel grating is its high load-bearing capacity. When properly designed and installed, it can support heavy machinery, equipment, and foot traffic while maintaining structural integrity.

2. Safety Features The open design of welded steel grating enhances safety by reducing the risk of slipping or falling. The gaps allow for water, debris, and other substances to drain away, minimizing hazards associated with wet or slippery surfaces.

3. Ease of Installation Welded steel grating is relatively easy to install, requiring minimal tools and labor. The panels can be cut to size and fitted into various applications, making it a practical choice for contractors and builders.

welded steel grating

4. Low Maintenance Unlike other flooring materials, welded steel grating requires little maintenance. Its durable construction resists corrosion and rust, especially when treated with protective coatings, which prolong its lifespan even in harsh environments.

5. Versatility This type of grating is used in a wide range of applications, from industrial flooring and safety platforms to catwalks and stair treads. It is equally effective in commercial settings, such as retail outlets and public buildings, where a combination of aesthetics and functionality is essential.

Applications

Welded steel grating is extensively used across various sectors. In industrial settings, it is often found in manufacturing plants, chemical facilities, and waste treatment sites. Here, it serves as flooring for conveyor systems, drainage covers, and access walkways. Its load-bearing properties make it suitable for use in heavy machinery sectors, where safety and structural integrity are paramount.

In the construction of commercial properties, welded steel grating provides an attractive solution for mezzanines, balconies, and ventilation grilles. Its ability to allow light and air to pass through enhances the overall environment while still providing the necessary support.

Conclusion

In summary, welded steel grating represents an essential element of modern construction and industrial design, offering unmatched strength, safety, and versatility. Whether used in heavy-duty industrial settings or aesthetic commercial applications, its benefits are clear. The combination of durability with low maintenance makes it an ideal solution for a myriad of environments. As industries continue to evolve and demand more innovative materials, welded steel grating is likely to remain at the forefront of structural solutions, ensuring safe and efficient operations in various applications. Embracing this technology will not only enhance productivity but also contribute to the longevity of infrastructure in a sustainable manner.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025