- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Load Capacity Tables for Steel Bar Grating Applications and Specifications

Understanding Steel Bar Grating Load Tables

Steel bar grating is a versatile and durable construction material often used in various industrial, commercial, and infrastructural applications. Its design, characterized by a series of parallel bars held together by cross bars, offers high strength-to-weight ratios, making it an ideal choice for walkways, platforms, floorings, and drainage covers. A critical aspect of the use of steel bar grating is understanding its load-bearing capacity, which can be effectively determined through load tables.

What are Load Tables?

Load tables are comprehensive charts that provide essential information regarding the load-carrying capabilities of different types of steel bar gratings. These tables facilitate the selection of appropriate grating by detailing the maximum allowable loads based on the grating’s specific dimensions, spacing of bars, and material properties. They help engineers, architects, and designers ensure that the chosen grating will safely support expected loads in various applications.

Key Parameters in Load Tables

1. Grating Depth The depth of the grating, measured in inches, significantly impacts its load-bearing capacity. Generally, deeper gratings can support higher loads due to increased rigidity.

2. Bar Spacing The spacing between the load-carrying bars is another critical element. Standard spacing values can range from 1 inch to 4 inches, influencing both the load capacity and the durability of the grating.

3. Load Type Load tables often categorize different types of loads—uniformly distributed loads (UDL) and concentrated loads. Understanding these distinctions is vital because they affect how the grating reacts under different stress conditions.

steel bar grating load tables

4. Material While steel is the most common material used, variations in steel grade and finish can lead to differing load capacities. Load tables often specify the material properties, including yield strength, to help users make informed decisions.

5. Deflection Limits Another important aspect of load tables is the allowable deflection under specific loads. Excessive deflection can lead to structural failures or safety hazards, turning a load-bearing structure into a potential liability.

Applications and Considerations

Steel bar grating finds extensive use in a variety of fields, including manufacturing plants, power plants, wastewater treatment facilities, and commercial buildings. When selecting the appropriate steel bar grating, professionals must consider the intended application and the specific loading requirements. Load tables provide the data needed to determine which grating will meet safety standards while also considering cost-effectiveness and longevity.

For instance, in a manufacturing environment where heavy machinery is present, selecting a grating with higher depth and narrower spacing would ensure that it can handle potential concentrated loads without failure. In contrast, for pedestrian walkways, lighter duty grating may suffice, favoring aesthetics and cost savings over maximum load capacity.

Final Thoughts

Understanding steel bar grating load tables is crucial for ensuring successful and safe applications across construction and industry. These tables provide invaluable information that aids in the selection of suitable products tailored to specific load requirements. With the right choice of grating, projects can be completed efficiently while adhering to safety regulations and design standards. Consequently, whether for pedestrian walkways, industrial floors, or drainage systems, comprehending load tables ultimately leads to better decision-making in the use of steel bar grating.

-

Welded Steel Bar Grating: The Strongest Choice for Industrial FlooringNewsMay.21,2025

-

Steel Grating for Sale: The Ultimate Anti-Slip SolutionNewsMay.21,2025

-

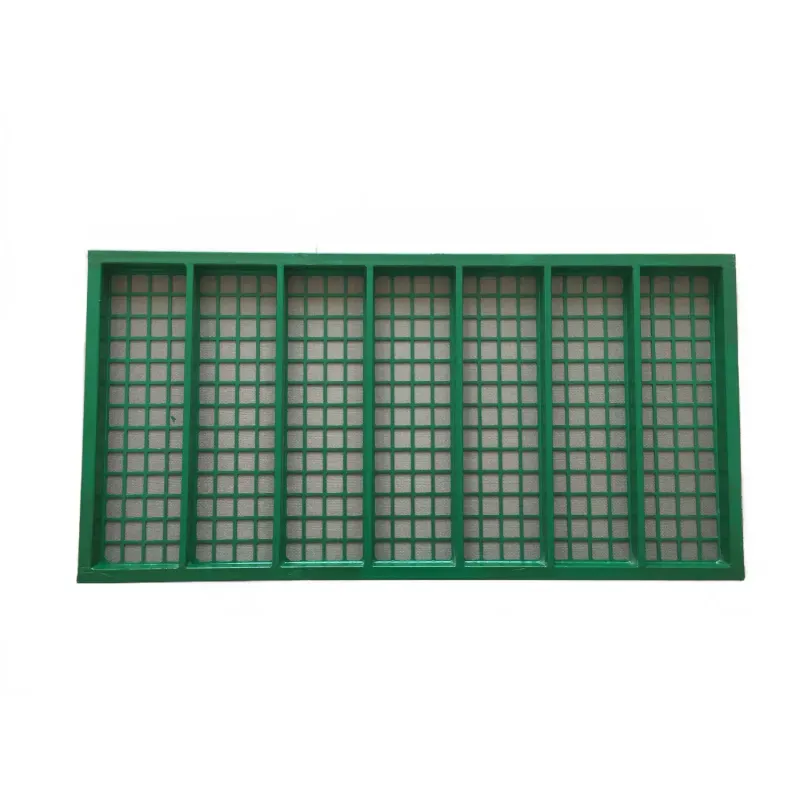

Steel Frame Shaker Screens: Unmatched Durability for Demanding OperationsNewsMay.21,2025

-

Shaker Screens: Your Ultimate Solution for Oil & Gas FiltrationNewsMay.21,2025

-

Press Locked Steel Grating: The Smarter Choice for Heavy-Duty FlooringNewsMay.21,2025

-

Helicopter Deck Safety Nets: Protect Your Crew and EquipmentNewsMay.21,2025