- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

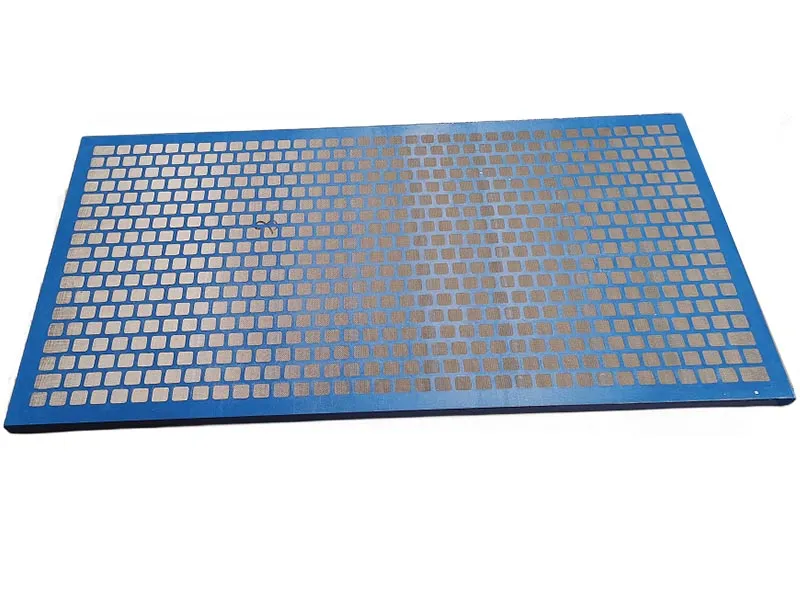

galvanised grating

The Versatility and Benefits of Galvanized Grating

Galvanized grating, an essential component in various industrial and commercial applications, is revered for its durability, strength, and corrosion resistance. Utilized widely in environments where exposure to elements can accelerate wear, galvanized grating presents a practical choice for construction and infrastructure needs. This article will explore the features, benefits, and applications of galvanized grating, emphasizing its importance in modern design and engineering.

What is Galvanized Grating?

Galvanized grating typically refers to a type of steel grating that has undergone a galvanization process, wherein a protective zinc coating is applied to the surface. This process not only enhances the steel's inherent strength but also creates a barrier against rust and corrosion, which is particularly crucial in environments where moisture and chemicals are prevalent. The grating itself generally consists of a series of parallel bars that are welded together, forming an open mesh pattern that allows for maximum drainage and airflow.

Benefits of Galvanized Grating

1. Corrosion Resistance One of the standout features of galvanized grating is its ability to withstand corrosive elements. The zinc coating acts as a sacrificial layer, protecting the underlying steel from rust and degradation. This quality significantly extends the lifespan of the product, making it a cost-effective solution in the long run.

2. Strength and Durability With its robust construction, galvanized grating can handle heavy loads and high traffic, making it suitable for industrial applications such as walkways, platforms, and drainage covers. It is designed to endure challenging conditions, including extreme weather and heavy footfall.

3. Low Maintenance Requirements Thanks to its corrosion-resistant properties, galvanized grating requires minimal maintenance. Unlike untreated steel, which may need regular painting or replacement, galvanized options can remain functional and aesthetically pleasing for years with little intervention.

4. Versatile Applications The versatility of galvanized grating is remarkable. It is employed in various settings, including manufacturing plants, petrochemical facilities, water treatment plants, and commercial buildings. Its adaptable design allows for custom sizes and configurations, catering to specific project needs.

5. Economic Efficiency While the initial investment might be higher compared to non-galvanized alternatives, the long-term savings resulting from reduced maintenance and replacement costs make galvanized grating an economically sound choice. The longevity and durability it provides outweigh the upfront expenditure.

galvanised grating

Applications of Galvanized Grating

The various applications of galvanized grating are vast

- Industrial Flooring In factories and warehouses, galvanized grating can be used as flooring that supports heavy machinery while allowing for drainage and visibility beneath.

- Walkways and Platforms It is ideal for constructing safe walkways and platforms that are essential in areas of high foot traffic or potential exposure to hazardous materials.

- Drainage Solutions With its open design, galvanized grating is effective in drainage systems, allowing for efficient water runoff while preventing clogging.

- Coolings Towers and Roofs In power generation facilities and other industrial setups, galvanized grating’s ability to resist corrosion makes it suitable for use in cooling towers and rooftop installations.

- Vehicle Access Many construction sites and industrial yards use galvanized grating for vehicle access roads, providing a sturdy yet lightweight solution for heavy machinery and trucks.

Conclusion

In summary, galvanized grating is a valuable asset across numerous industries due to its exceptional durability, corrosion resistance, and versatility. As businesses and contractors continue to prioritize cost-effective, long-lasting materials, galvanized grating is likely to remain a preferred choice for structural and safety applications. Whether it is for industrial flooring, walkways, or drainage systems, the advantages of galvanized grating make it an indispensable component in modern engineering and construction. By understanding its benefits and potential applications, stakeholders can make informed decisions that contribute to both safety and efficiency in their projects.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025