- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jan . 20, 2025 12:13

Back to list

concrete weight coating

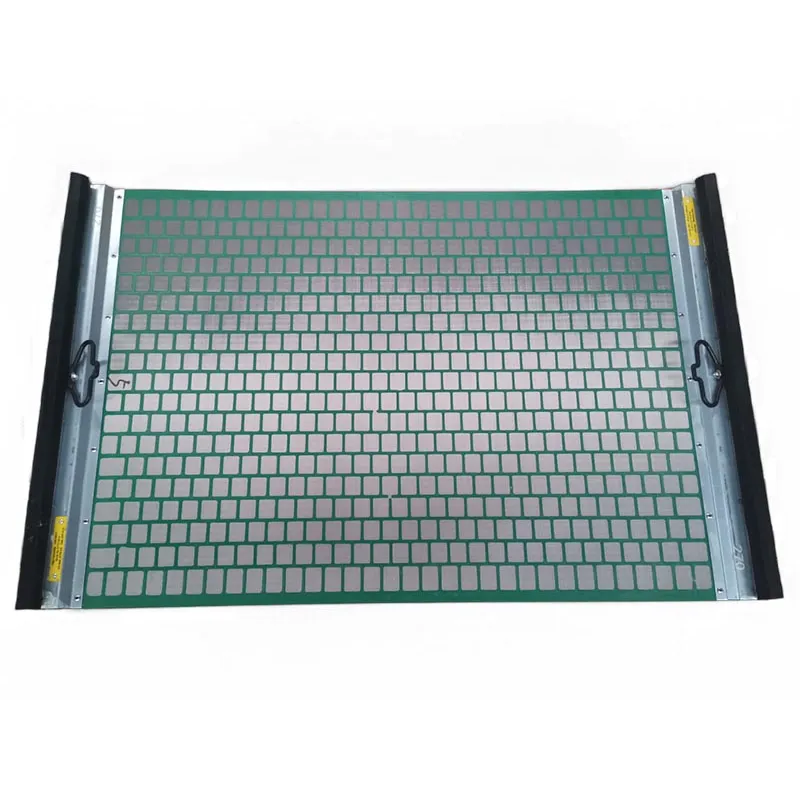

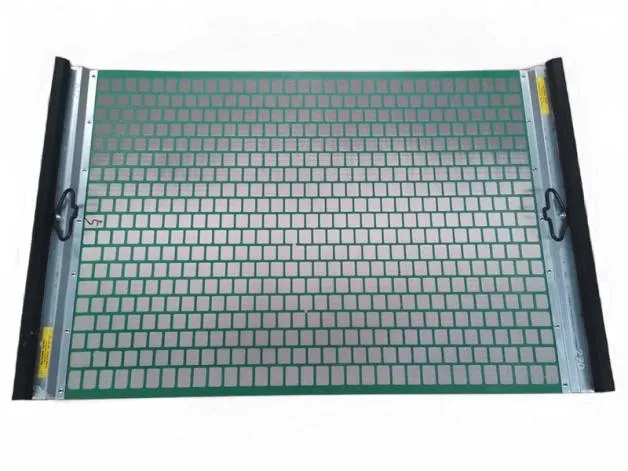

Aluminum grating is known for its lightweight properties and effective utility in various industrial applications. Its weight is a critical factor influencing its selection and implementation across different sectors, mainly due to its significant impact on transportation, installation, and structural integrity. As an expert in architectural and industrial materials, I will provide insights on the factors influencing aluminum grating weight and its implications on design and functionality.

In industries focused on safety, such as oil and gas or chemical processing plants, aluminum grating provides a crucial balance between strength and weight. Its ability to withstand corrosive agents while maintaining a manageable weight makes it ideal for offshore platforms and refining facilities where material integrity is paramount. Transportation costs are another area where aluminum grating's weight advantage becomes evident. Lighter materials mean lower fuel costs and easier handling, reducing logistics expenses and making it an economically viable option for large-scale projects. This is particularly beneficial in temporary setups or relocations, where the grating must be moved multiple times. Environmental and sustainability factors also enhance the appeal of aluminum grating from a weight perspective. The reduction in weight corresponds to lower emissions in both production and transportation phases, aligning with global efforts towards sustainable construction practices. Additionally, aluminum is highly recyclable, contributing further to its eco-friendly credentials. By understanding these factors, engineers, architects, and decision-makers can make informed choices about aluminum grating, balancing weight and performance to meet specific project requirements. The strategic use of aluminum grating can lead to efficient, durable, and economically sound solutions across various sectors, showcasing its value as a modern construction and industrial material. In summary, the weight of aluminum grating is more than just a physical characteristic; it is a pivotal factor that influences material choice, project costs, and operational efficiency. Recognizing its benefits and potential applications reinforces aluminum grating's essential role in contemporary architecture and industry, maintaining its status as a high-demand material. For those seeking a reliable, lightweight, and versatile material, aluminum grating continues to deliver on all fronts.

In industries focused on safety, such as oil and gas or chemical processing plants, aluminum grating provides a crucial balance between strength and weight. Its ability to withstand corrosive agents while maintaining a manageable weight makes it ideal for offshore platforms and refining facilities where material integrity is paramount. Transportation costs are another area where aluminum grating's weight advantage becomes evident. Lighter materials mean lower fuel costs and easier handling, reducing logistics expenses and making it an economically viable option for large-scale projects. This is particularly beneficial in temporary setups or relocations, where the grating must be moved multiple times. Environmental and sustainability factors also enhance the appeal of aluminum grating from a weight perspective. The reduction in weight corresponds to lower emissions in both production and transportation phases, aligning with global efforts towards sustainable construction practices. Additionally, aluminum is highly recyclable, contributing further to its eco-friendly credentials. By understanding these factors, engineers, architects, and decision-makers can make informed choices about aluminum grating, balancing weight and performance to meet specific project requirements. The strategic use of aluminum grating can lead to efficient, durable, and economically sound solutions across various sectors, showcasing its value as a modern construction and industrial material. In summary, the weight of aluminum grating is more than just a physical characteristic; it is a pivotal factor that influences material choice, project costs, and operational efficiency. Recognizing its benefits and potential applications reinforces aluminum grating's essential role in contemporary architecture and industry, maintaining its status as a high-demand material. For those seeking a reliable, lightweight, and versatile material, aluminum grating continues to deliver on all fronts.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025