- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 14, 2025 16:01

Back to list

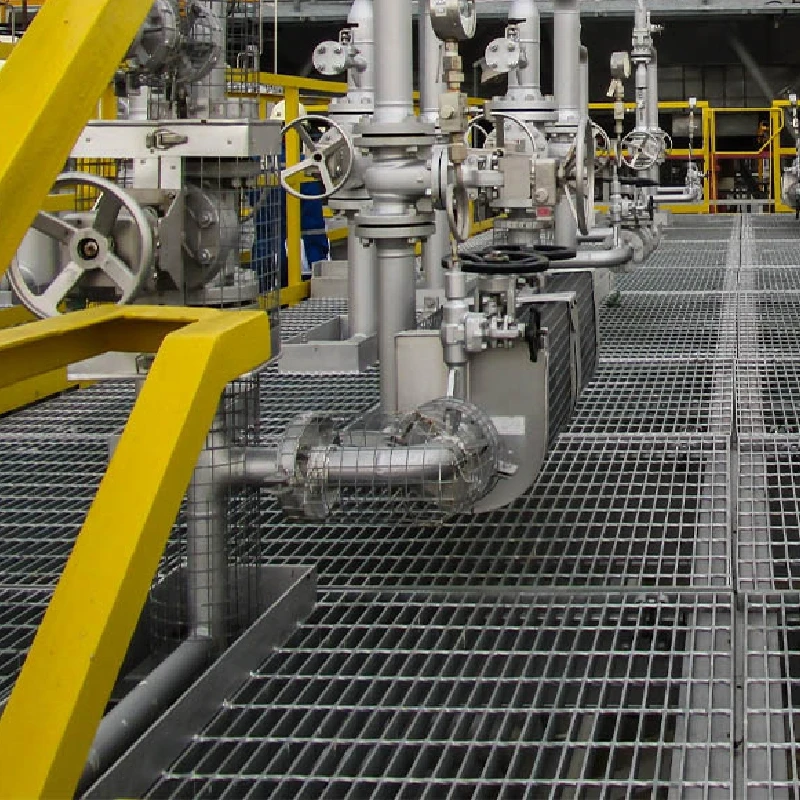

heavy-duty welded bar grating

Bar grating systems are indispensable elements in a variety of industrial and commercial settings, offering unmatched strength and versatility. The significance of 19W4 bar grating weight in these applications cannot be overstated, as it directly influences the performance, safety, and efficiency of installations.

Manufacturers of 19W4 bar grating design their products with consistency in quality and precision of dimensions, which are paramount for users who seek repeatability and reliability in their applications. This reliability helps maintain an organization's reputation by ensuring that public and worker safety is commensurate with regional and international safety standards. When planning the deployment of 19W4 bar grating, the fabrication process and finishing techniques, such as galvanization, are crucial factors as they directly affect weight. Galvanization, for example, adds a protective zinc layer to steel gratings, enhancing corrosion resistance while slightly adding to the overall weight. This trade-off is typically justified by the extended longevity and reduced maintenance associated with galvanized surfaces. Installation considerations must also take into account the grating weight. Heavier sections may require additional lifting equipment and workforce, which could impact the timeline and budget if not correctly anticipated and planned for. Nevertheless, the weight provides the robustness needed for use in challenging environments, favorably offsetting these initial logistic considerations with long-term durability and safety. In the realm of customizations, 19W4 bar gratings can be modified to specific client requirements, including adjustments to bar thickness and additional treatments for improved wear resistance. Such customizations alter the weight characteristics but allow for a tailored fit in specialized applications where off-the-shelf solutions might fall short. In conclusion, the weight of 19W4 bar grating is a pivotal factor that defines its applications and performance in diverse environments. Stakeholders must carefully assess this characteristic to ensure that their selected grating solution aligns with project goals, optimizes cost-effectiveness, and guarantees operational safety and longevity in its intended application. Through a nuanced understanding of 19W4 bar grating weight along with its related design specifications, businesses can make well-informed decisions that uphold both safety standards and economic efficiency.

Manufacturers of 19W4 bar grating design their products with consistency in quality and precision of dimensions, which are paramount for users who seek repeatability and reliability in their applications. This reliability helps maintain an organization's reputation by ensuring that public and worker safety is commensurate with regional and international safety standards. When planning the deployment of 19W4 bar grating, the fabrication process and finishing techniques, such as galvanization, are crucial factors as they directly affect weight. Galvanization, for example, adds a protective zinc layer to steel gratings, enhancing corrosion resistance while slightly adding to the overall weight. This trade-off is typically justified by the extended longevity and reduced maintenance associated with galvanized surfaces. Installation considerations must also take into account the grating weight. Heavier sections may require additional lifting equipment and workforce, which could impact the timeline and budget if not correctly anticipated and planned for. Nevertheless, the weight provides the robustness needed for use in challenging environments, favorably offsetting these initial logistic considerations with long-term durability and safety. In the realm of customizations, 19W4 bar gratings can be modified to specific client requirements, including adjustments to bar thickness and additional treatments for improved wear resistance. Such customizations alter the weight characteristics but allow for a tailored fit in specialized applications where off-the-shelf solutions might fall short. In conclusion, the weight of 19W4 bar grating is a pivotal factor that defines its applications and performance in diverse environments. Stakeholders must carefully assess this characteristic to ensure that their selected grating solution aligns with project goals, optimizes cost-effectiveness, and guarantees operational safety and longevity in its intended application. Through a nuanced understanding of 19W4 bar grating weight along with its related design specifications, businesses can make well-informed decisions that uphold both safety standards and economic efficiency.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025