- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

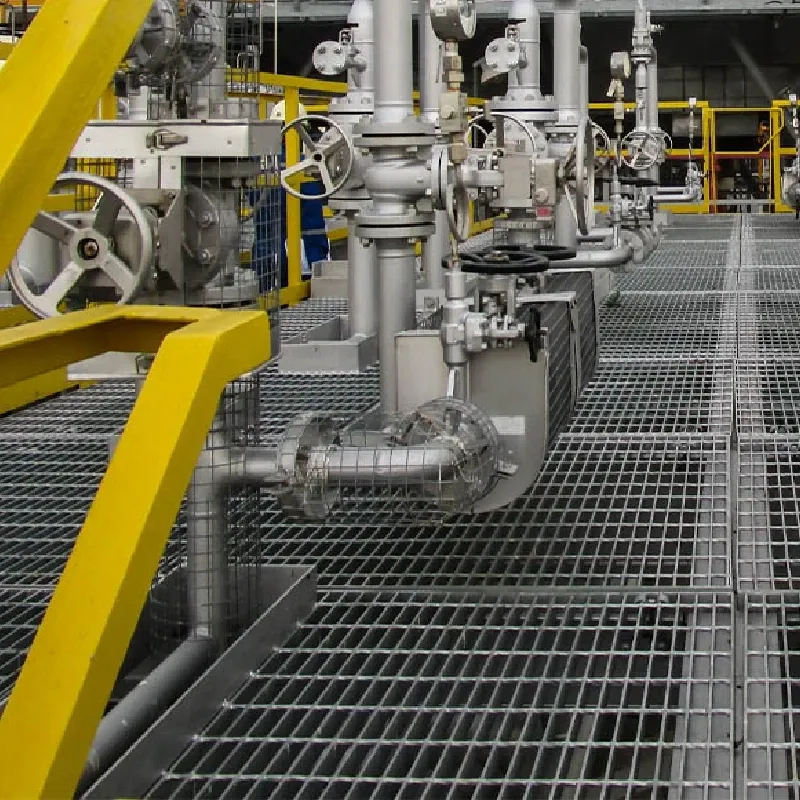

Galvanised Steel Grid Mesh Flooring Heavy-Duty & Weatherproof

- Understanding Galvanised Grid Solutions for Industrial Applications

- Technical Advantages of Galvanised Steel Grid Systems

- Comparing Top Manufacturers: Performance Metrics & Durability

- Customisation Options for Galvanised Grid Mesh Flooring

- Case Studies: Real-World Applications Across Industries

- Installation Best Practices and Maintenance Guidelines

- Future Trends in Galvanised Grid Technology

(galvanised grid)

Understanding Galvanised Grid Solutions for Industrial Applications

Galvanised grid systems, including galvanised steel grid and galvanised grid

mesh flooring, have become indispensable in sectors requiring robust, corrosion-resistant infrastructure. These products are engineered using hot-dip galvanisation, a process that coats steel with a zinc layer, enhancing longevity by up to 4x compared to untreated alternatives. Industries such as construction, logistics, and agriculture rely on these grids for load-bearing platforms, walkways, and safety barriers, where a single panel can withstand loads exceeding 1,500 kg/m².

Technical Advantages of Galvanised Steel Grid Systems

Galvanised steel grids offer unmatched mechanical properties. Key benefits include:

- Corrosion Resistance: Zinc coatings of 80–100 microns provide 25+ years of service in harsh environments.

- Weight Efficiency: High strength-to-weight ratios reduce structural support costs by 30%.

- Safety Compliance: Anti-slip surfaces achieve DIN 51130 R10–R13 ratings, critical for OSHA-compliant workplaces.

Comparing Top Manufacturers: Performance Metrics & Durability

| Manufacturer | Coating Thickness (microns) | Max Load Capacity (kg/m²) | Warranty Period | Price per m² (USD) |

|---|---|---|---|---|

| SteelGrid Pro | 95 | 1,800 | 20 years | 85 |

| ZincShield Industries | 85 | 1,600 | 15 years | 72 |

| DuraMesh Solutions | 105 | 2,000 | 25 years | 98 |

Customisation Options for Galvanised Grid Mesh Flooring

Tailored galvanised grid solutions address specific project requirements. Customisation parameters include:

- Panel Dimensions: Modular designs from 500x500mm to 3,000x1,200mm.

- Mesh Density: Adjustable bar spacing (10–50mm) for varying load and debris management needs.

- Coating Upgrades: Additional epoxy or powder coatings for extreme pH or temperature environments.

Case Studies: Real-World Applications Across Industries

Automotive Manufacturing: A German car plant installed 2,500 m² of galvanised grid mesh flooring, reducing maintenance costs by 40% over five years. Renewable Energy: Offshore wind farms utilise galvanised steel grids with 120-micron coatings to resist saltwater corrosion, achieving 99.6% uptime.

Installation Best Practices and Maintenance Guidelines

Proper installation ensures optimal performance. Critical steps include:

- Substrate preparation with ≤3mm level tolerance

- Welded or bolted connections rated for ≥1.5x expected loads

- Annual inspections using ASTM A123 compliance checklists

Future Trends in Galvanised Grid Technology

Innovations like nano-coated galvanised grids and AI-driven corrosion monitoring systems are reshaping the industry. Manufacturers now integrate IoT sensors into galvanised steel grid panels, enabling predictive maintenance and extending service life to 35+ years. These advancements position galvanised grid mesh flooring as a cornerstone of sustainable industrial design.

(galvanised grid)

FAQS on galvanised grid

Q: What are the primary uses of galvanised grid mesh flooring?

A: Galvanised grid mesh flooring is ideal for industrial walkways, drainage covers, and safety platforms. Its zinc coating resists corrosion, making it suitable for wet or outdoor environments. The open-grid design allows debris and liquids to pass through easily.

Q: How does galvanised steel grid differ from regular steel grid?

A: Galvanised steel grid undergoes a zinc-coating process to prevent rust and corrosion, unlike untreated steel. This makes it 3-5 times more durable in harsh weather or chemical exposure. It maintains structural strength while requiring less maintenance.

Q: Can galvanised grid support heavy machinery?

A: Yes, high-grade galvanised grids with 50mm x 10mm steel bars can bear loads up to 3 tonnes/m². Load capacity depends on grid thickness and welding quality. Always verify manufacturer specifications for industrial applications.

Q: Why choose galvanised grid over fiberglass alternatives?

A: Galvanised grid offers superior heat resistance (up to 400°C) and higher load capacity compared to fiberglass. It's more cost-effective for permanent installations, though slightly heavier. Zinc coating provides better UV stability than plastic composites.

Q: How to maintain galvanised grid mesh flooring?

A: Rinse with water quarterly to remove corrosive salts or chemicals. Inspect for zinc coating damage annually - touch up with cold galvanizing spray if needed. Avoid pressure washing above 1,500 PSI to preserve the protective layer.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025