- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Serrated Grating Design and Applications in Optical Devices and Sensors

Understanding Serrated Type Grating A Technical Overview

Serrated type grating is an innovative optical component that has garnered significant attention in various fields such as photonics, telecommunications, and spectroscopy. Characterized by its unique teeth-like structure, serrated gratings are designed to manipulate light with enhanced efficiency and precision. This article provides an overview of serrated type grating, exploring its design, applications, and advantages over traditional grating types.

Design and Structure

Serrated gratings are distinguished by their periodic serrations or notches, which can be fabricated on materials such as metal, glass, or semiconductor substrates. These serrations can be designed with different depths, widths, and spacing, allowing for tailored optical performance. The fundamental principle behind serrated gratings lies in their ability to diffract light into several orders, creating specific angles of diffraction based on the incident wavelength.

The configuration of the serrations allows these gratings to achieve both a high diffraction efficiency and low polarization sensitivity. This means that they can effectively function across a wide range of wavelengths while maintaining performance consistency regardless of the polarization state of incoming light.

Applications of Serrated Type Grating

The unique properties of serrated type grating make it suitable for a variety of applications. One prominent use is in spectroscopic systems, where the grating can help analyze the spectral composition of light. By diffracting incoming light into its constituent wavelengths, serrated gratings enable researchers to gather critical data on materials and chemical compositions.

In telecommunications, serrated gratings can be used in wavelength division multiplexing (WDM) systems, allowing multiple signals to be transmitted simultaneously through the same optical fiber. This capability is essential for increasing data bandwidth and improving communication efficiency.

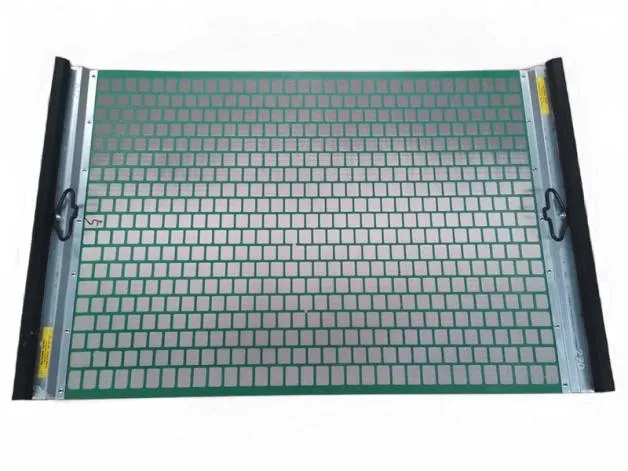

serrated type grating

Another area of application is in the development of laser systems. Serrated gratings are employed in laser beam shaping, helping to control the output beam profile and optimize laser performance. In this context, the precision and efficiency of serrated gratings contribute to advancements in various laser technologies used in medicine, industrial processing, and scientific research.

Advantages of Serrated Type Grating

One of the significant advantages of serrated type gratings is their improved efficiency compared to traditional ruled gratings. The serrated structure reduces scattering losses and enhances the coupling of light into diffracted beams. As a result, serrated gratings can achieve higher diffraction efficiencies across a broader wavelength range, making them ideal for applications where performance is critical.

Moreover, serrated type gratings exhibit better thermal stability and resistance to environmental factors, which ensures consistent performance over time. This durability is particularly valuable in applications where equipment may be subject to varying temperatures and conditions.

In addition to practical benefits, the design flexibility offered by serrated gratings allows engineers and researchers to tailor optical devices to meet specific needs. This adaptability opens doors to innovative applications that were not previously feasible with conventional grating technologies.

Conclusion

Serrated type grating represents a significant advancement in optical design, providing unique advantages in efficiency, durability, and versatility. As technology continues to evolve, the role of serrated gratings in photonics and related fields is expected to expand further, paving the way for new innovations in light manipulation and optical engineering. Understanding and harnessing the potential of these gratings can lead to improved systems in both research and practical applications, demonstrating the dynamic interplay between design and functionality in modern optics.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025