- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 05, 2025 01:09

Back to list

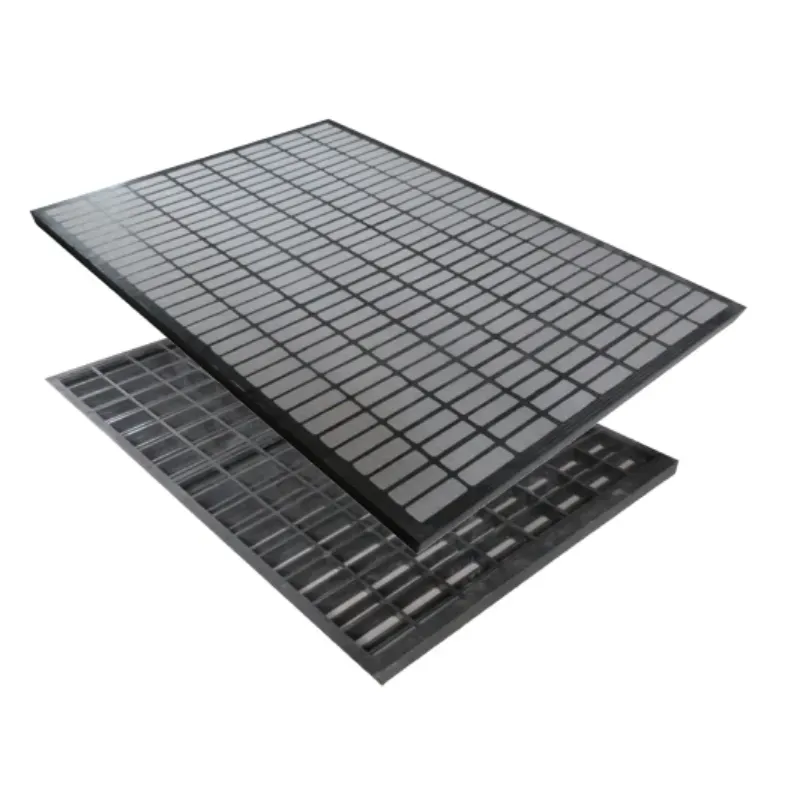

galvanised steel grating

Galvanised steel grating is increasingly becoming a vital component in numerous industrial applications, gaining popularity due to its exceptional durability and versatile functionality. The process of galvanisation, involving the application of a protective zinc coating, significantly enhances the steel's resistance to corrosion—a frequent challenge in environments exposed to moisture or chemicals. This critical characteristic makes galvanised steel grating an ideal choice for a wide array of industries, from petrochemicals to food processing facilities.

Quality assurance is another critical factor enhancing the trustworthiness of galvanised steel grating. Reputable manufacturers adhere to international standards such as ISO 9001 and ISO 1461, ensuring that every piece of grating meets stringent quality and performance benchmarks. This rigorous quality control process not only fosters trust among buyers but also signifies a commitment to delivering value and excellence. To further augment its benefits, experts recommend regular inspection and maintenance to preserve its condition over the years. Preventive maintenance schedules can identify potential issues such as excessive wear or accidental damage before they escalate into major problems. By doing so, businesses not only safeguard their investment but also affirm the trust placed in galvanised steel grating as a cornerstone component in their operations. In conclusion, galvanised steel grating stands out as a product characterized by durability, versatility, and reliability—a preferred choice among experienced industry professionals. Its capacity to meet and exceed various industrial requirements, coupled with endorsements from seasoned experts, cements its place as an authoritative and trustworthy component in today’s market. Whether for industrial, architectural, or commercial use, galvanised steel grating exemplifies a convergence of practical functionality and proven quality, ensuring it will continue to be a staple in numerous applications worldwide.

Quality assurance is another critical factor enhancing the trustworthiness of galvanised steel grating. Reputable manufacturers adhere to international standards such as ISO 9001 and ISO 1461, ensuring that every piece of grating meets stringent quality and performance benchmarks. This rigorous quality control process not only fosters trust among buyers but also signifies a commitment to delivering value and excellence. To further augment its benefits, experts recommend regular inspection and maintenance to preserve its condition over the years. Preventive maintenance schedules can identify potential issues such as excessive wear or accidental damage before they escalate into major problems. By doing so, businesses not only safeguard their investment but also affirm the trust placed in galvanised steel grating as a cornerstone component in their operations. In conclusion, galvanised steel grating stands out as a product characterized by durability, versatility, and reliability—a preferred choice among experienced industry professionals. Its capacity to meet and exceed various industrial requirements, coupled with endorsements from seasoned experts, cements its place as an authoritative and trustworthy component in today’s market. Whether for industrial, architectural, or commercial use, galvanised steel grating exemplifies a convergence of practical functionality and proven quality, ensuring it will continue to be a staple in numerous applications worldwide.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025