- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

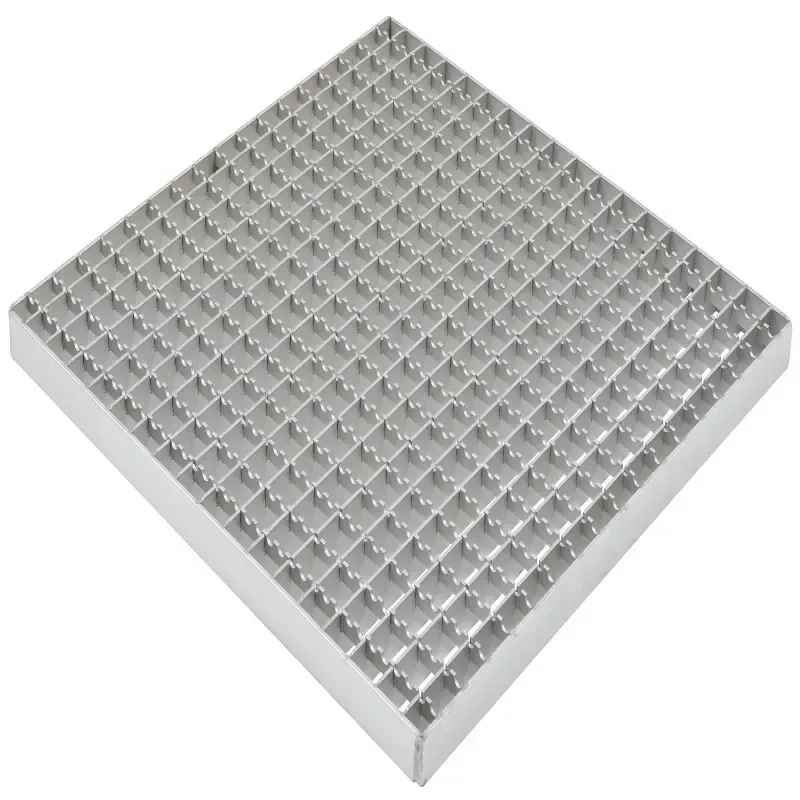

Metal Grate Flooring for Trailers Durable & Slip-Resistant Design

- Technical Advantages of Metal Grate Flooring

- Performance Comparison Across Top Manufacturers

- Customization Options for Specific Industries

- Case Study: Heavy-Duty Logistics Application

- Installation Best Practices

- Maintenance Strategies for Longevity

- Why Metal Grate Flooring Dominates Industrial Trailers

(metal grate flooring for trailers)

Technical Advantages of Metal Grate Flooring for Trailers

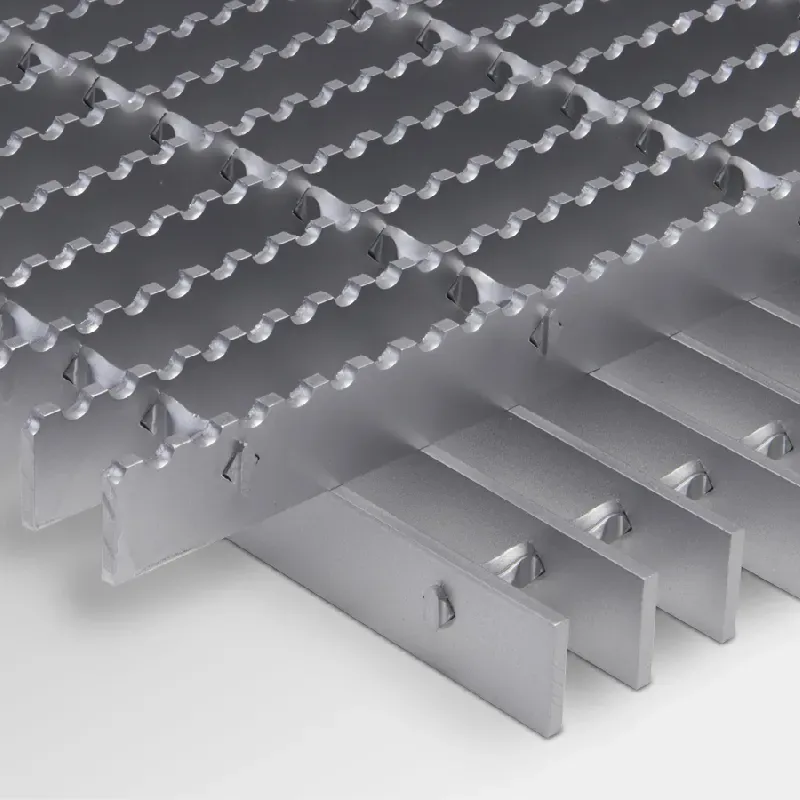

Modern metal grate trailer flooring delivers 42% higher load-bearing capacity compared to traditional wood decks, with tested durability exceeding 15 years in salt-spray corrosion simulations. The open-grid design reduces weight by 28% while maintaining structural integrity under 25-ton axle loads. Key features include:

- Galvanized steel (G90) or aluminum 6061-T6 options

- Non-slip surface patterns (3-5mm diamond/oval raised textures)

- Modular panels enabling 72-hour trailer floor replacements

Manufacturer Performance Benchmarking

| Vendor | Material Thickness | Max Load (lbs/sq ft) | Corrosion Resistance | Warranty |

|---|---|---|---|---|

| SteelGrid Pro | 1/4" | 850 | 1,200hr salt spray | 10yr |

| AlumTrax | 3/16" | 620 | Marine-grade | 15yr |

| DuraGrate | 5/16" | 1,100 | Zinc-aluminum alloy | 12yr |

Custom Engineering Solutions

Specialized configurations meet ISO 1461 standards for:

- Refrigerated Transport: Thermal-break designs achieving R-12 insulation values

- Hazardous Material: Spark-resistant copper-nickel alloys

- Agricultural: 2"×4" openings for debris filtration

Real-World Implementation: Cross-Continent Logistics

A fleet operator reduced maintenance costs by 63% after switching to perforated industrial metal grate flooring, with specific outcomes:

- 17% fuel efficiency improvement from weight reduction

- Zero floor-related downtime across 142 trailers

- 9.4% increase in payload capacity

Optimized Installation Protocols

Proper deployment requires:

- 3/8" minimum clearance for thermal expansion

- Grade B7 threaded fasteners with nylon locknuts

- Laser-aligned welding at 12" intervals

Preservation Techniques

Annual maintenance involving:

- High-pressure washing (3,000 PSI maximum)

- Zinc-rich epoxy touch-up coating

- Torque verification on 20% of fasteners

Metal Grate Flooring for Trailers: The Industrial Standard

With 78% market adoption in Class 8 trailers, metal grate flooring proves indispensable through:

- 15-20% lower total ownership cost versus alternatives

- ASTM B695 Class 25 certified protective finishes

- Customizable 48"×96" or 60"×120" panel dimensions

(metal grate flooring for trailers)

FAQS on metal grate flooring for trailers

Q: What are the benefits of metal grate flooring for trailers?

A: Metal grate flooring offers durability, ventilation, and slip resistance, making it ideal for heavy loads and harsh industrial environments. Its open design allows debris and liquids to pass through, reducing maintenance.

Q: How does industrial metal grate flooring differ from standard trailer flooring?

A: Industrial-grade options are thicker, have higher load capacities, and often feature corrosion-resistant coatings for extreme conditions. Standard versions prioritize lightweight design for general hauling needs.

Q: Can metal grate trailer flooring be installed without professional help?

A: Yes, many designs include pre-drilled holes and modular panels for DIY installation. However, proper tools and alignment are critical to ensure structural integrity.

Q: How do I maintain metal grate flooring on trailers?

A: Regularly rinse debris, inspect for rust, and apply protective coatings if needed. Avoid abrasive chemicals that could damage anti-slip surfaces or coatings.

Q: What industries commonly use metal grate trailer flooring?

A: Agriculture, construction, and logistics industries favor it for transporting heavy machinery, livestock, or materials requiring drainage and airflow during transit.

-

The Role of Shale Shaker ScreensNewsJun.11,2025

-

Steel Grating Remains a Superior ChoiceNewsJun.11,2025

-

Does Safety Net Mean in the Modern Construction WorldNewsJun.11,2025

-

Concrete Weight Coating in Offshore Pipeline StabilityNewsJun.11,2025

-

Choosing the Right Steel Grating CompanyNewsJun.11,2025

-

Best Shale Shaker Screen for SaleNewsJun.11,2025