- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 06, 2025 00:44

Back to list

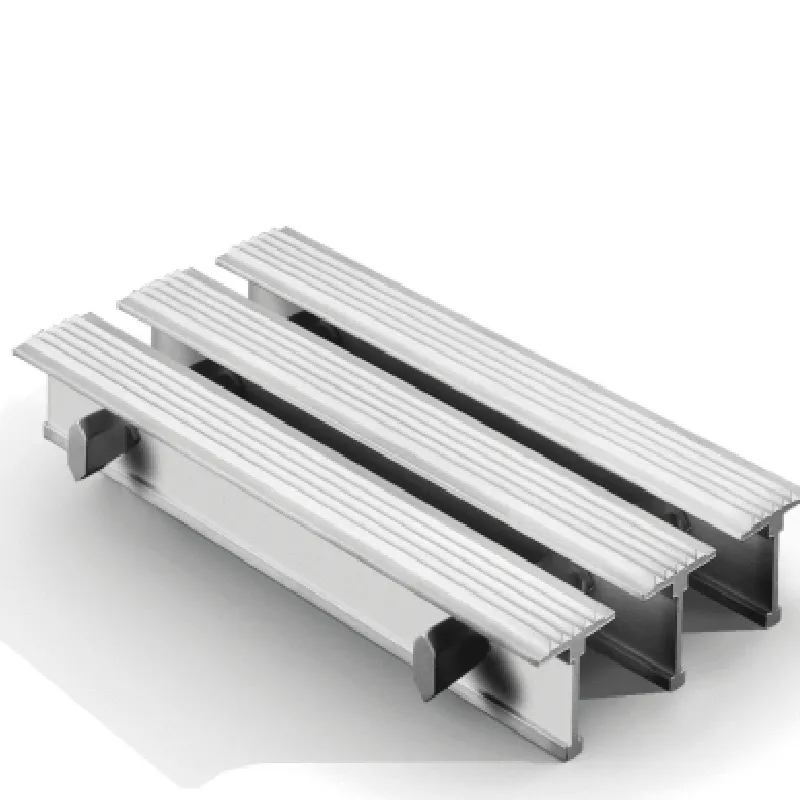

steel grating galvanized

Steel gratings have become an indispensable component in various industrial and commercial applications, primarily due to their strength, durability, and versatility. While there are different types of steel grating available, galvanized steel grating stands out for its exceptional resistance to corrosion and rust. This article dives into the unique benefits and applications of galvanized steel grating, emphasizing its reliability and expert-preferred qualities.

In addition to safety, galvanized steel grating is lauded for its ecological advantages. The zinc coating process is environmentally friendly and complies with modern sustainability standards. Once the grating reaches the end of its lifecycle, it can be recycled without losing its metallurgical properties, aligning with the growing emphasis on environmentally conscious construction materials. This makes galvanized steel grating an authoritative choice for those looking to minimize environmental impact while maintaining structural efficiency. Maintenance professionals have noted that galvanized steel grating requires minimal upkeep. The protective zinc coating significantly reduces the need for frequent inspections or repairs, allowing organizations to allocate resources more efficiently. Its resilience to damage ensures that once installed, the grating can perform optimally for decades, showcasing the material's long-term cost-effectiveness and reliability. For users seeking a blend of strength, safety, and environmental responsibility, galvanized steel grating is the material of choice. Its wide range of applications further showcases its flexibility, from industrial plants and parking decks to drainage systems and urban infrastructure projects. Regardless of the environment, galvanized steel grating upholds its reputation as a dependable and expert-approved solution. To conclude, galvanized steel grating combines strength, durability, and unbeatable resistance to potential environmental threats, making it an authoritative and trustworthy option for various projects. Its expert-endorsed features continue to inspire confidence across industries, offering a balanced solution that meets the high standards of today's construction and industrial landscapes.

In addition to safety, galvanized steel grating is lauded for its ecological advantages. The zinc coating process is environmentally friendly and complies with modern sustainability standards. Once the grating reaches the end of its lifecycle, it can be recycled without losing its metallurgical properties, aligning with the growing emphasis on environmentally conscious construction materials. This makes galvanized steel grating an authoritative choice for those looking to minimize environmental impact while maintaining structural efficiency. Maintenance professionals have noted that galvanized steel grating requires minimal upkeep. The protective zinc coating significantly reduces the need for frequent inspections or repairs, allowing organizations to allocate resources more efficiently. Its resilience to damage ensures that once installed, the grating can perform optimally for decades, showcasing the material's long-term cost-effectiveness and reliability. For users seeking a blend of strength, safety, and environmental responsibility, galvanized steel grating is the material of choice. Its wide range of applications further showcases its flexibility, from industrial plants and parking decks to drainage systems and urban infrastructure projects. Regardless of the environment, galvanized steel grating upholds its reputation as a dependable and expert-approved solution. To conclude, galvanized steel grating combines strength, durability, and unbeatable resistance to potential environmental threats, making it an authoritative and trustworthy option for various projects. Its expert-endorsed features continue to inspire confidence across industries, offering a balanced solution that meets the high standards of today's construction and industrial landscapes.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025