- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jan . 19, 2025 23:30

Back to list

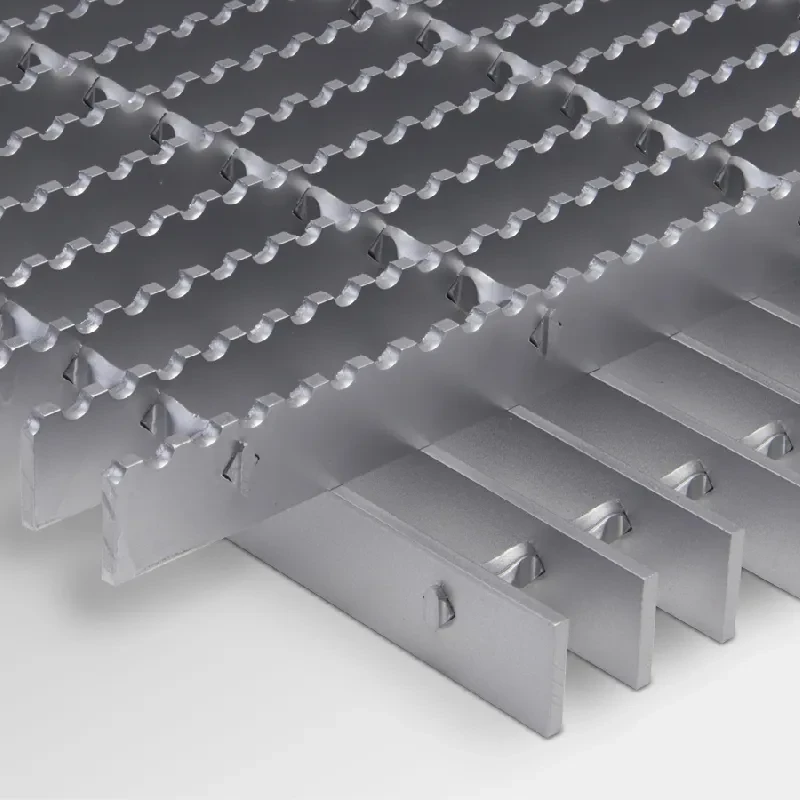

galvanised metal grate

The advent of galvanised metal grates has revolutionized industries by providing durable and reliable solutions for drainage, safety, and support applications. These grates are coated with a layer of zinc, which not only enhances their strength but also serves as a robust barrier against corrosion, a critical feature for installations in challenging environments. Industries ranging from construction and manufacturing to agriculture and urban planning have increasingly recognized the value of galvanised metal grates in maintaining functionality and safety over extended periods.

From an environmental perspective, galvanised metal grates present a sustainable option. The longevity and durability result in fewer replacements, thus reducing the material consumption and waste associated with frequent replacements. Additionally, the zinc utilized in galvanisation is recyclable, aligning with eco-friendly practices and regulations that are increasingly becoming stringent across the globe. Urban developers and environmental consultants are finding these grates to be consistent with green building initiatives and sustainable development goals. In the realm of product reliability and consumer trust, galvanised metal grates establish their market authority through certified manufacturing processes that adhere to international standards. Professional associations and governing bodies often underscore the reliability of galvanised products through rigorous testing and accreditation, ensuring that end-users have confidence in the performance and safety of their investments. Engineers, architects, and procurement managers seeking certified and dependable grate solutions widely endorse these products owing to their proven track record and verified compliance. The use of galvanised metal grates, with their exceptional balance of durability, safety, and environmental friendliness, supports a myriad of applications essential for both modern infrastructure and traditional industries. Their adoption demonstrates a forward-thinking approach to engineering challenges, environment-conscious construction, and the ever-important aspect of user safety. As industries continue to evolve, the deployment of galvanised metal grates will undoubtedly remain a cornerstone of innovation, fortifying structures and protecting assets in ways that align with the benchmarks of advanced engineering practices.

From an environmental perspective, galvanised metal grates present a sustainable option. The longevity and durability result in fewer replacements, thus reducing the material consumption and waste associated with frequent replacements. Additionally, the zinc utilized in galvanisation is recyclable, aligning with eco-friendly practices and regulations that are increasingly becoming stringent across the globe. Urban developers and environmental consultants are finding these grates to be consistent with green building initiatives and sustainable development goals. In the realm of product reliability and consumer trust, galvanised metal grates establish their market authority through certified manufacturing processes that adhere to international standards. Professional associations and governing bodies often underscore the reliability of galvanised products through rigorous testing and accreditation, ensuring that end-users have confidence in the performance and safety of their investments. Engineers, architects, and procurement managers seeking certified and dependable grate solutions widely endorse these products owing to their proven track record and verified compliance. The use of galvanised metal grates, with their exceptional balance of durability, safety, and environmental friendliness, supports a myriad of applications essential for both modern infrastructure and traditional industries. Their adoption demonstrates a forward-thinking approach to engineering challenges, environment-conscious construction, and the ever-important aspect of user safety. As industries continue to evolve, the deployment of galvanised metal grates will undoubtedly remain a cornerstone of innovation, fortifying structures and protecting assets in ways that align with the benchmarks of advanced engineering practices.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025