- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

helmi . 13, 2025 00:33

Back to list

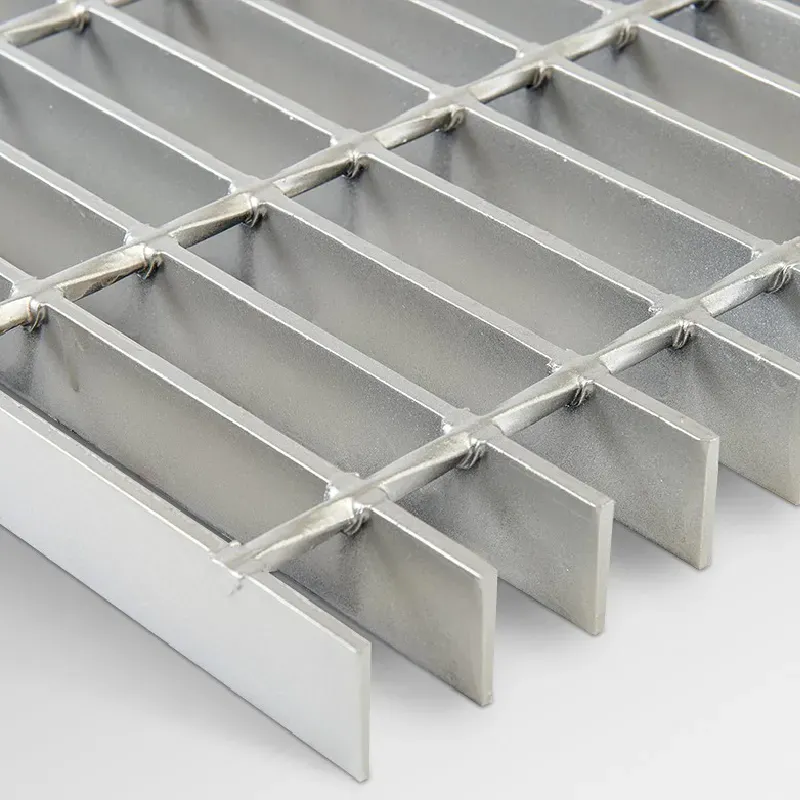

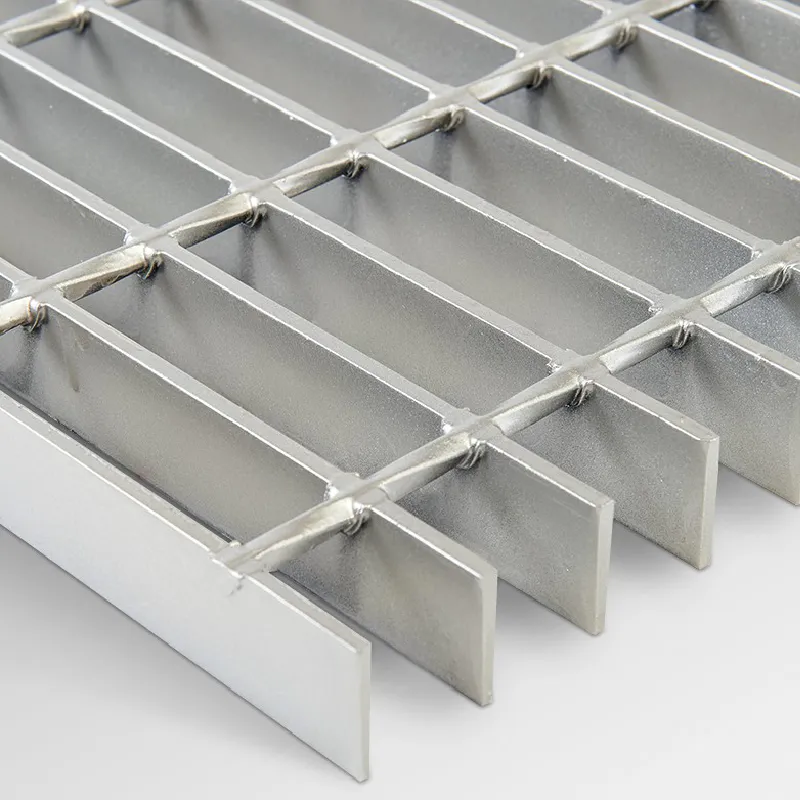

steel walkway grating

Stainless steel grating is an essential component for a wide range of industrial applications, owing to its durability, resistance to corrosion, and non-slip properties. For those within fields such as construction, manufacturing, or any sector that requires sturdy flooring solutions, understanding stainless steel grating specifications is crucial for ensuring safety and effectiveness.

Expert installation and maintenance further enhance the longevity and effectiveness of stainless steel grating. Ensuring that the grating is securely fastened using the right clips and fasteners prevents any displacement that could lead to hazards. Regular inspection and cleaning are necessary steps to maintain the grating's integrity and performance, particularly in environments where debris and residues could accumulate and cause corrosion over time. In terms of sustainability, stainless steel is highly recyclable, aligning with many industries' environmental goals. Beyond its recyclability, the longevity and robust nature of stainless steel grating mean fewer replacements and lower lifecycle costs, making it an economically viable option despite the higher initial investment compared to other materials. Instructors and experts in the field, such as civil engineers and industrial safety officers, consistently recommend stainless steel grating for its balance of strength, safety, and durability. Its authority in industrial settings is unmatched due to its performance in corrosive environments, low maintenance needs, and compliance with industry safety standards. When seeking reliable stainless steel grating suppliers, it's imperative to engage with businesses that not only offer certified products but also possess a track record of expert advice and technical support. Trustworthy suppliers will provide detailed product specifications, including grade certifications and load-bearing tests, thus ensuring that each purchase meets the stringent demands of specific applications. In conclusion, the selection, installation, and maintenance of stainless steel grating must be approached with comprehensive knowledge of its specifications and industry requirements. This approach guarantees not only the optimal performance of the grating in diverse environments but also the manifest benefits of safety and durability, which are paramount in industrial applications.

Expert installation and maintenance further enhance the longevity and effectiveness of stainless steel grating. Ensuring that the grating is securely fastened using the right clips and fasteners prevents any displacement that could lead to hazards. Regular inspection and cleaning are necessary steps to maintain the grating's integrity and performance, particularly in environments where debris and residues could accumulate and cause corrosion over time. In terms of sustainability, stainless steel is highly recyclable, aligning with many industries' environmental goals. Beyond its recyclability, the longevity and robust nature of stainless steel grating mean fewer replacements and lower lifecycle costs, making it an economically viable option despite the higher initial investment compared to other materials. Instructors and experts in the field, such as civil engineers and industrial safety officers, consistently recommend stainless steel grating for its balance of strength, safety, and durability. Its authority in industrial settings is unmatched due to its performance in corrosive environments, low maintenance needs, and compliance with industry safety standards. When seeking reliable stainless steel grating suppliers, it's imperative to engage with businesses that not only offer certified products but also possess a track record of expert advice and technical support. Trustworthy suppliers will provide detailed product specifications, including grade certifications and load-bearing tests, thus ensuring that each purchase meets the stringent demands of specific applications. In conclusion, the selection, installation, and maintenance of stainless steel grating must be approached with comprehensive knowledge of its specifications and industry requirements. This approach guarantees not only the optimal performance of the grating in diverse environments but also the manifest benefits of safety and durability, which are paramount in industrial applications.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025